TroubleshooTing and sysTem TesTs

5-4 powermax

45

Service Manual

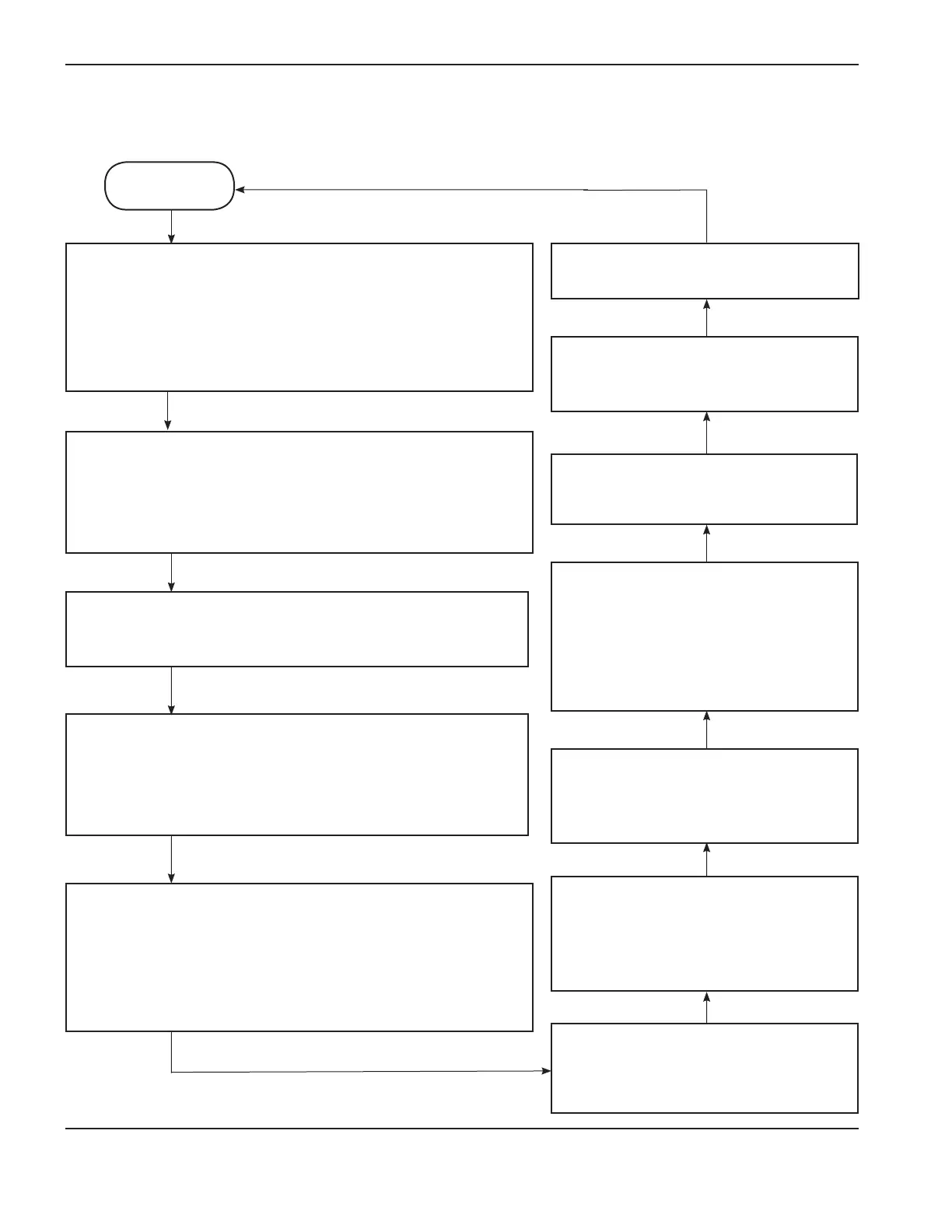

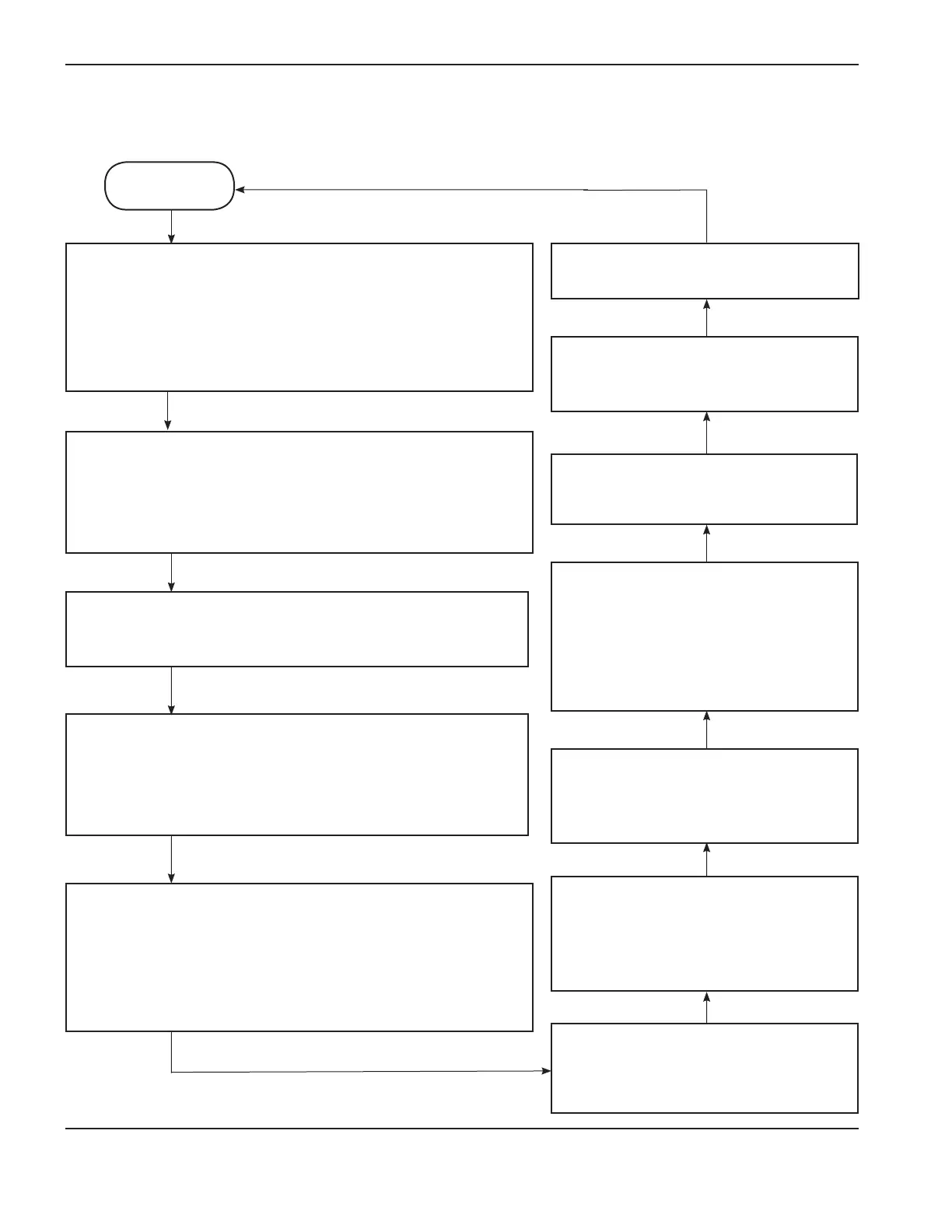

Sequence of operation

Power OFF

•Connect the gas supply to the air fitting on the power supply.

•Connect the work lead to the workpiece.

•Plug in the power supply and make sure incoming power is ON if using a

line-disconnect box.

•Set the ON/OFF switch(S1) to ON(I).

•Set the power switch(S1) to OFF(O).

•The gas solenoid valve(V1) closes.

•The gas flow stops.

•The arc extinguishes.

•Gas continues to flow for 20seconds.

•Drag the torch lightly across the workpiece to

make a cut.

•The workpiece drops after the cut.

•Release the plasma start trigger on the hand

torch or the remote start switch for the machine

torch.

•The gas solenoid valve(V1) opens.

•The gas flow starts.

•The cutting arc starts.

•Position the torch on the workpiece.

•Pull the plasma start trigger on the hand torch

or press the remote start switch for the machine

torch.

•The gas solenoid valve(V1) closes.

•The gas flow stops.

•The power circuits are ready.

•Turn the amperage adjustment knob to the gas test position.

•The gas solenoid valve(V1) opens to purge the system and to allow the

gas pressure to be set.

•The green power ON LED illuminates, indicating the system is ready for

operation.

•All the fault LEDs should be extinguished (see the Troubleshooting guide

on page 5-11 for more information).

•Verify that the gas pressure LED illuminates green and is centered in the

pressure bar.

•Set the amperage adjustment knob to the desired output current (between

20 and 45amps) based on the thickness of the metal to be cut.

•Set the mode switch to the desired mode for cutting or gouging.

Loading...

Loading...