page 12

1.5. Mounting of the modules

In order to expose the controller modules to the minimum

mechanical stress they should preferably be mounted

horizontally or vertically on the mounting panel. The module

must be fixed with four screws to DIN 7500 or DIN 7984 (M5 x

L).

If possible, the modules should be mounted in such a way that

the cable entry of the plug points downwards.

1.6. Electrical connection of the modules

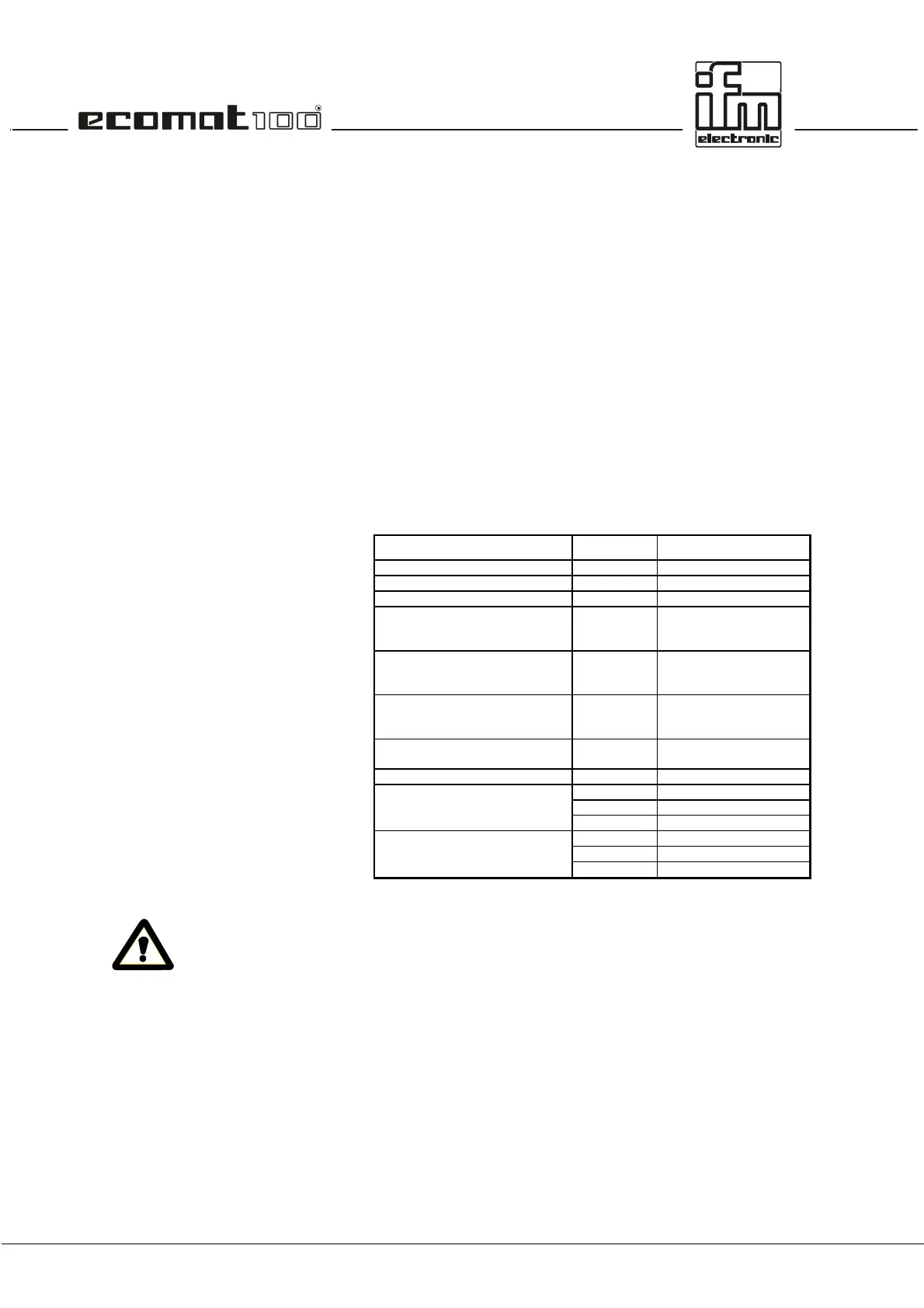

Before commissioning it must be ensured that the following pins

must/can be connected to the corresponding potentials.

To guarantee the electrical interference protection of the

controller modules, the housings must be connected to

the ground of the vehicle.

1.7. Fusing of the controller modules

In order to protect the whole system (cabling and controller) the

individual circuits must be fused accordingly, taking into account

the total current of 10 A of the individual output modules (max. 8

outputs – e.g. QX0.08 ... QX0.15).

Designation Pin No. Potential

Supply voltage 23 (VBB

S

) + 24 V DC

Ground 01 (GND

S

) GND

Analog ground 12 (GND

A

) GND

Supply voltage

outputs High-Side

without monitoring relay

05 (VBBo) + 24 V DC

Supply voltage

outputs High-Side

with monitoring relay

34 (VBB

R

) + 24 V DC

Supply voltage

outputs Low-Side

without monitoring relay

15 (GNDo) GND

Test input,

programming mode

24 (Test) + 24 V DC

Test input, operating mode 24 (Test) open

Programming interface RS 232 06 (RxD) Pin 03, PC 9pin SUB-D

07 (TxD) Pin 02, PC 9pin SUB-D

33 (CM

5

) Pin 05, PC 9pin SUB-D

CAN interface 14 (CAN

H

) CAN

H

further participant

32 (CAN

L

) CAN

L

further participant

33 (CM

5

) GND further participant

Loading...

Loading...