3D sensor

30

9.3.8 Transmit process values of the level measurement via PROFINET

The device can transmit the process values to a PLC via the PROFINET fieldbus. The process values are

displayed in the ifm Vision Assistant as output string as below:

Only one fieldbus can be active at a time. The fieldbus is adjustable (→ software manual).

The output string is transferred to a PLC in the displayed sequence.

Observe the following remarks for the transmission of the output string to a PLC:

● Bytes 0 to 7 are part of the output string. They are not displayed in the ifm Vision Assistant (see

screenshot above).

● Semicolons ";" in the output string are not transferred.

● Float values are converted into 16-bit integers before the transmission.

● All numerical values are converted into binary 16-bit integers before the transmission.

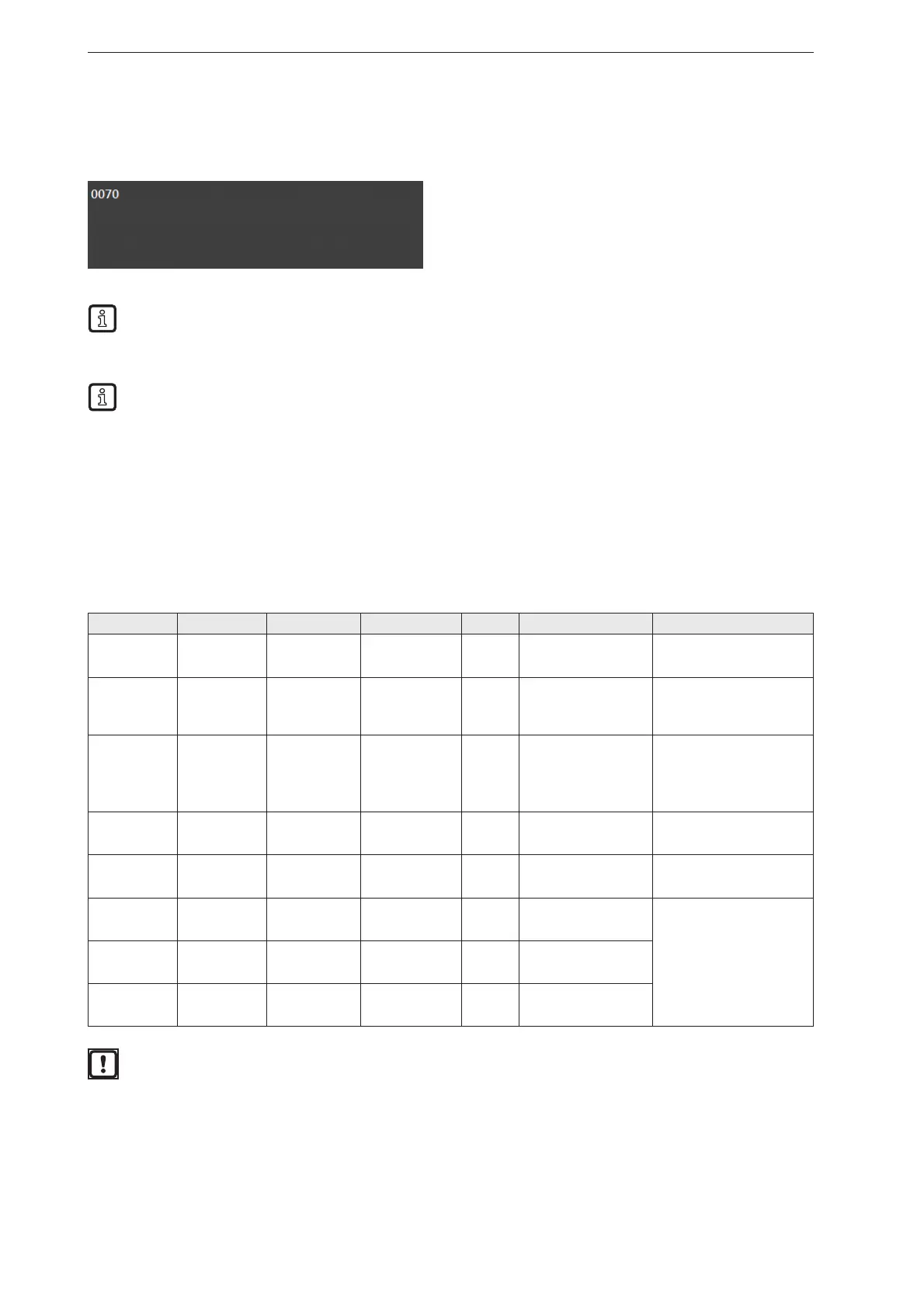

The output string is composed of the following:

0070

Byte no. Data Coding Process value Unit Description Comments

0 2#0010_0000 Binary

0.5

Duplicated

command word

Bit 0.5 shows a successful

trigger command

1 2#0000_0000 Binary

2 2#0000_0000 Decimal

Synchronous /

asynchronous

message

identification

3 2#0000_0000 Decimal

4 0 Decimal

30 Message counter

● The device has received

30 messages.

● Increments by 1 with

each action (trigger,

message sent etc.).

5 30 Decimal

6 0 Decimal

Reserved

7 0 Decimal

8 0 Decimal

0

Status of all ROIs

(0 = bad, 1 = good)

Shows the status of the

level measurement

9 0 Decimal

10 0 Decimal

0 ROI ID

ROI status:

0 = good

6 = overfill

7 = underfill

11 0 Decimal

12 0 Decimal

7 ROI status

13 7 Decimal

14 0 Decimal

0 mm ROI value

15 0 Decimal

Faulty execution of a command leads to the following status:

● Error bit = 1

● Duplicated command word is displayed

● Asynchronous message bit = 0

● Asynchronous message identification = 0

● Message counter increments by 1

Loading...

Loading...