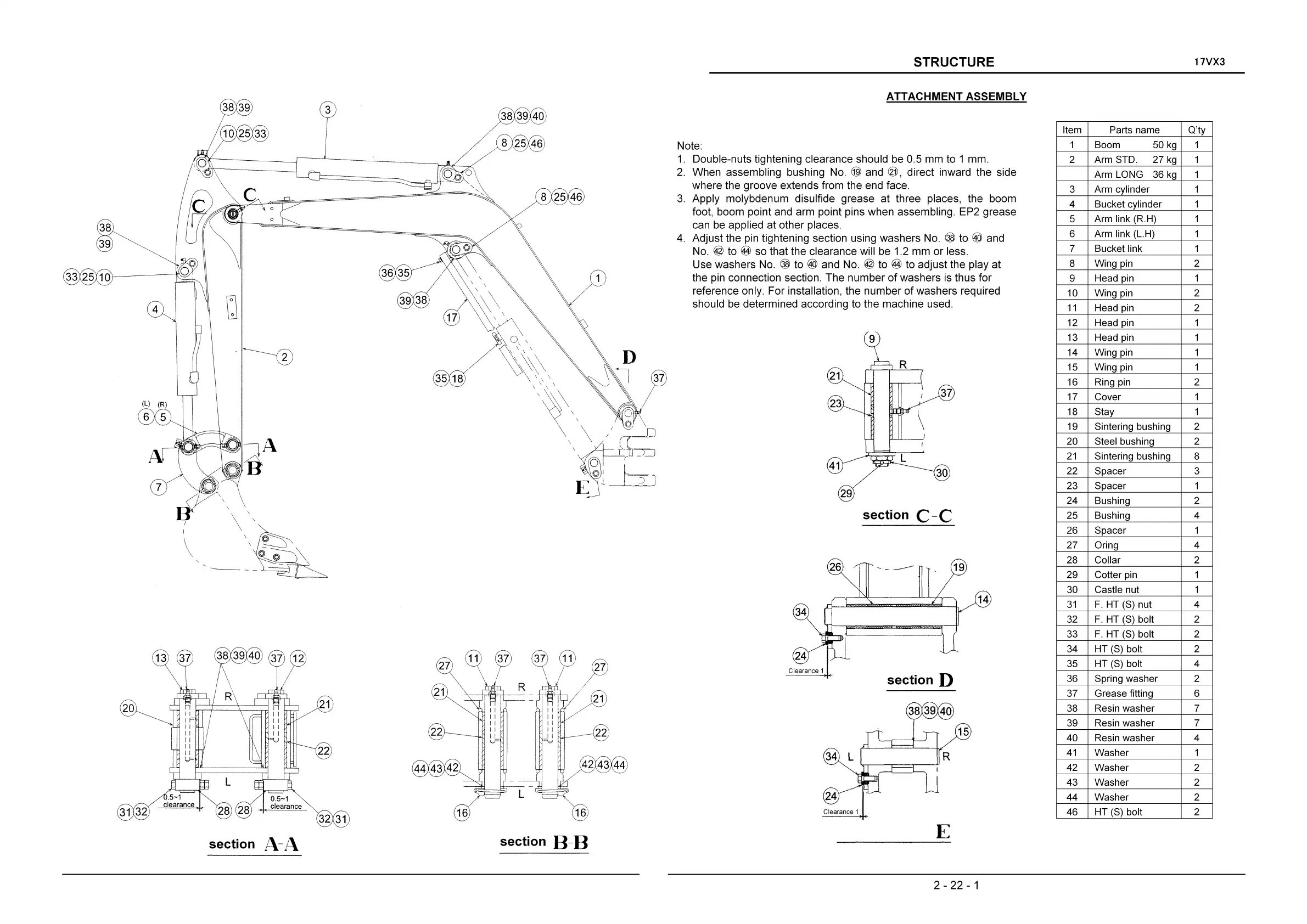

STRUCTURE

17VX3

Item Parts name

O'ty

1 Boom 50

kg

1

2 Arm STD. 27

kg

1

Arm LONG 36

kg

1

3

Arm cylinder 1

4 Bucket cylinder 1

5

Arm link (R.H) 1

6

Arm link (L.H) 1

7 Bucket link 1

8

Wing pin 2

9

Head pin 1

10 Wing pin 2

11

Head pin 2

12 Head pin 1

13 Head pin 1

14 Wing pin 1

15 Wing pin 1

16 Ring pin 2

17 Cover 1

18

Stay

1

19 Sintering bushing 2

20 Steel bushing 2

21

Sintering bushing

8

22 Spacer

3

23 Spacer 1

24 Bushing 2

25 Bushing 4

26 Spacer 1

27 Oring 4

28 Collar 2

29 Cotter pin 1

30

Castle nut 1

31

F.

HT (S) nut 4

32

F.

HT (S) bolt 2

33

F.

HT (S) bolt 2

34 HT (S) bolt 2

35

HT (S) bolt 4

36

Spring washer 2

37 Grease fitting

6

38

Resin washer 7

39

Resin washer 7

40 Resin washer 4

41

Washer 1

42 Washer 2

43 Washer 2

44 Washer 2

46 HT (S) bolt 2

37

Clearance 1

E

24

9

24

34

L

ATTACHMENT

ASSEMBLY

34

Clearance 1

section D

Note:

1.

Double-nuts tightening clearance should be 0.5

mm

to 1 mm.

2.

When

assembling bushing No. @ and ®, direct inward the side

where

the

groove

extends from the end face.

3.

Apply

molybdenum

disulfide grease

at

three places, the boom

foot, boom point and arm point pins

when

assembling. EP2

grease

can be applied

at

other

places.

4.

Adjust

the pin tightening section using

washers

No. @ to ® and

No.

© to @ so that the clearance will be 1.2

mm

or

less.

Use

washers

No. @ to ® and No. © to @ to adjust the play

at

the pin connection section.

The

number

of

washers

is thus

for

reference only.

For

installation, the

number

of

washers

required

should be determined according to the machine used.

22

42 43 44

?

21

16

8 25 46

38 39 40

section B-B

16

36 35

21

32

31

22

\0

~----

__

J

38 39

section A-A

30

29

section

C-C

\

\

\

-----

26

.......

_---

38

39

33

25

10

2 - 22 - 1

Loading...

Loading...