Thermal Metrology

22 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

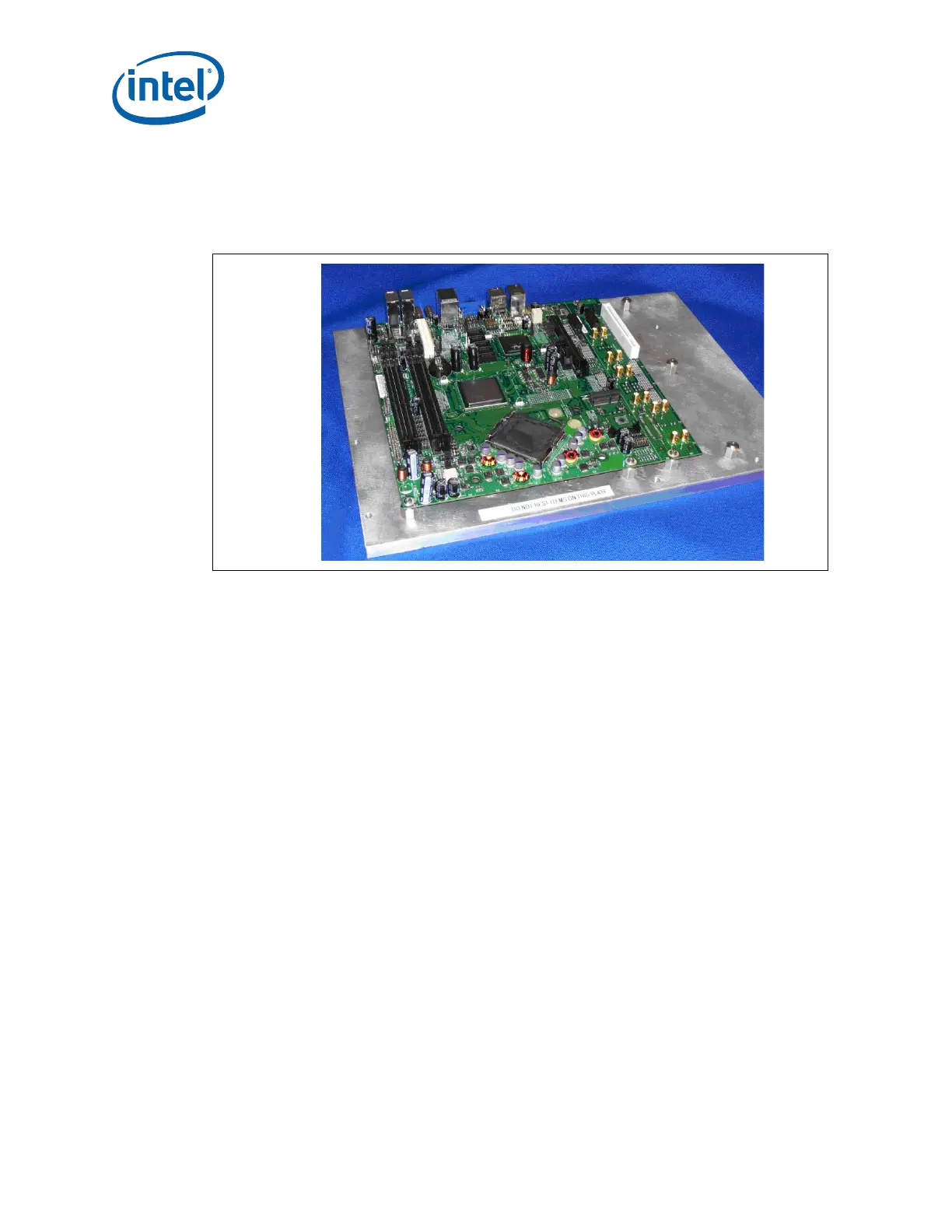

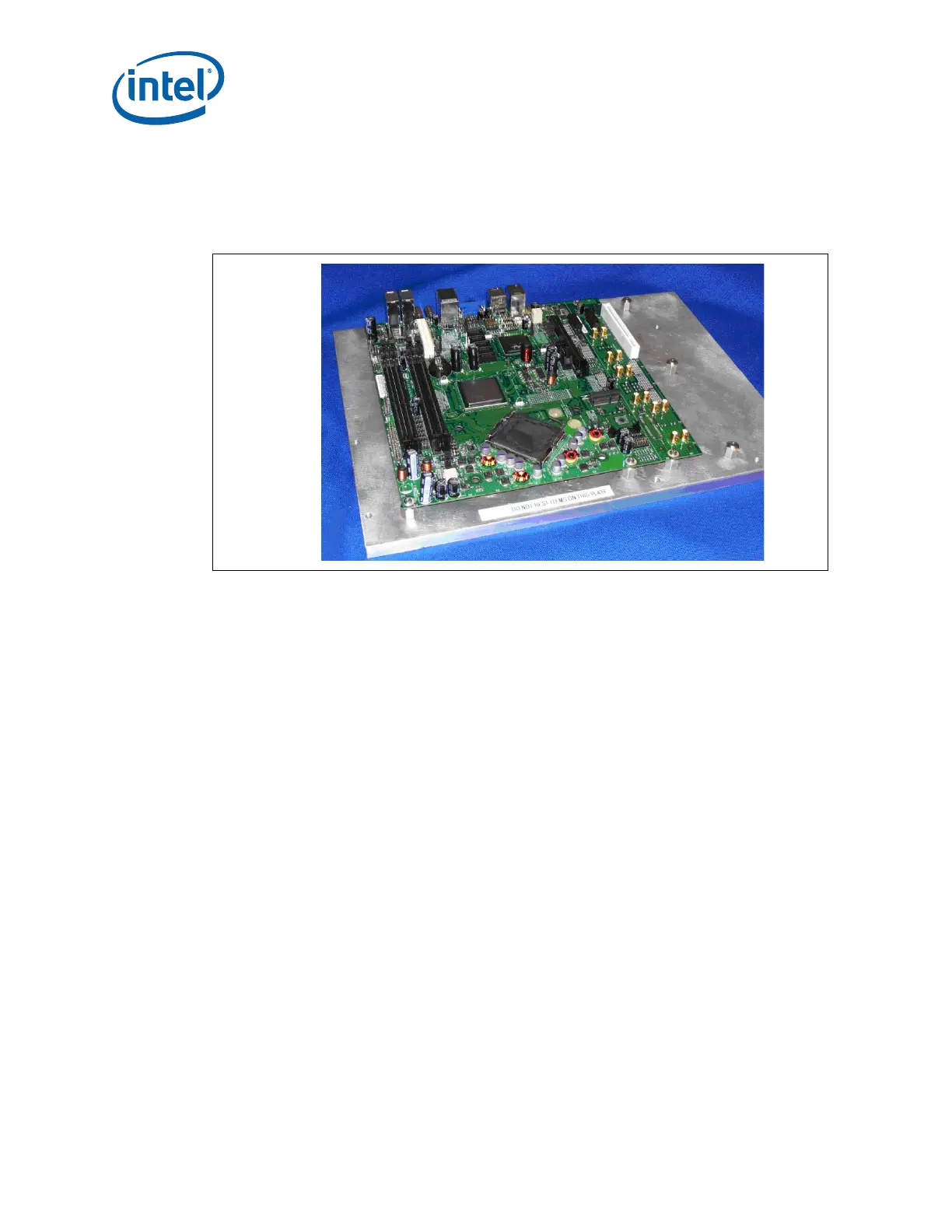

Select a machine shop that is capable of holding drawing-specified tolerances. IHS

groove geometry is critical for repeatable placement of the thermocouple bead,

ensuring precise thermal measurements. A fixture plate should be used to machine the

IHS groove on the FCBGA7 Chipset Package on the Live Board. Refer to Figure 5-4.

5.1.4 Thermocouple Attach Procedure

In order to accomplish the thermocouple attach procedure, the following steps are

required:

1. Thermocouple conditioning and preparation

2. Thermocouple attach to the IHS

3. Soldering process

4. Cleaning and completion of the thermocouple installation

5.1.4.1 Thermocouple Conditioning and Preparation

1. Use a calibrated thermocouple, as specified in Section 5.1.3.

2. Under a microscope verify the thermocouple insulation meets the quality

requirements. The insulation should be about 1/16 inch (0.062 ± 0.030) from the

end of the bead. Refer to Figure 5-5.

Figure 5-4. The Live Board on the Fixture Plate

Loading...

Loading...