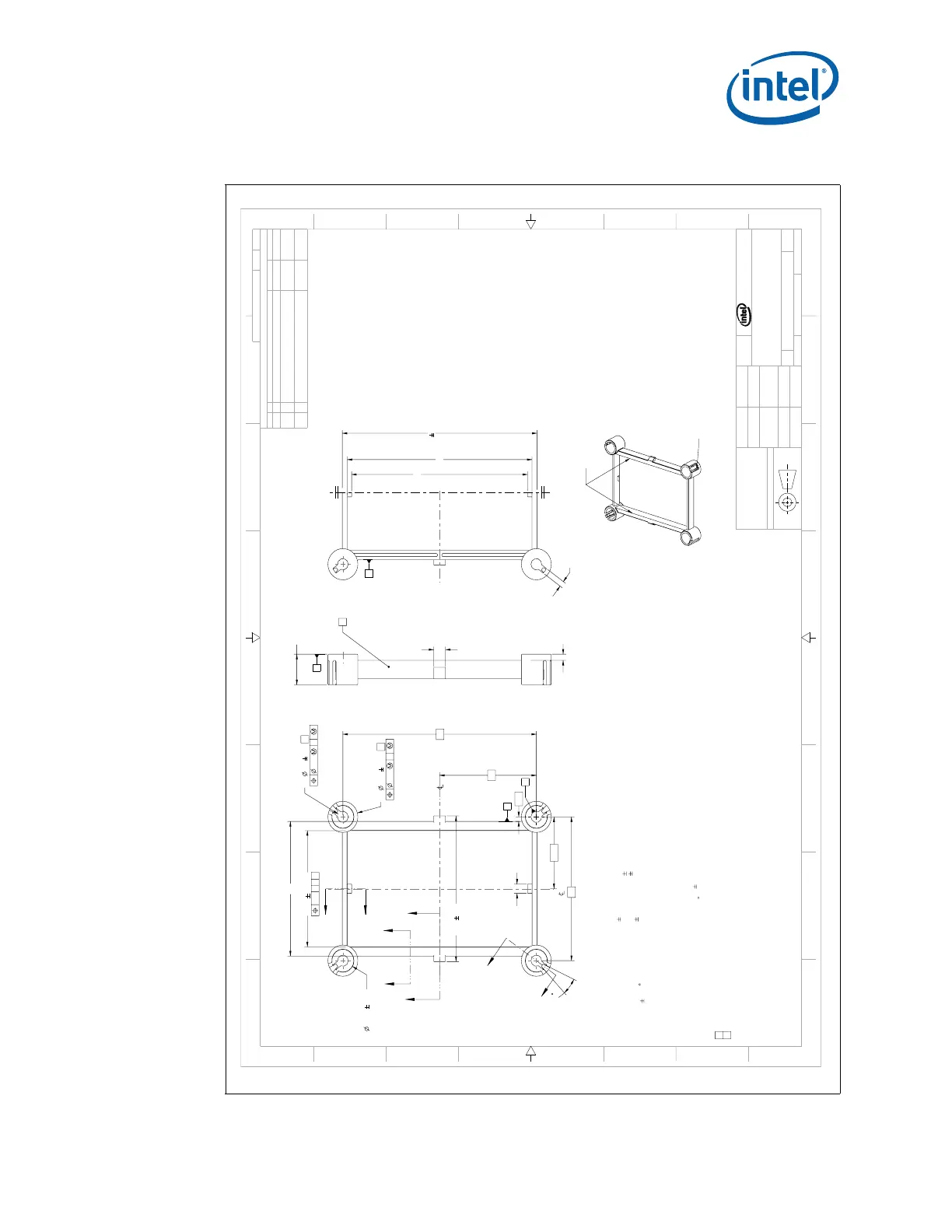

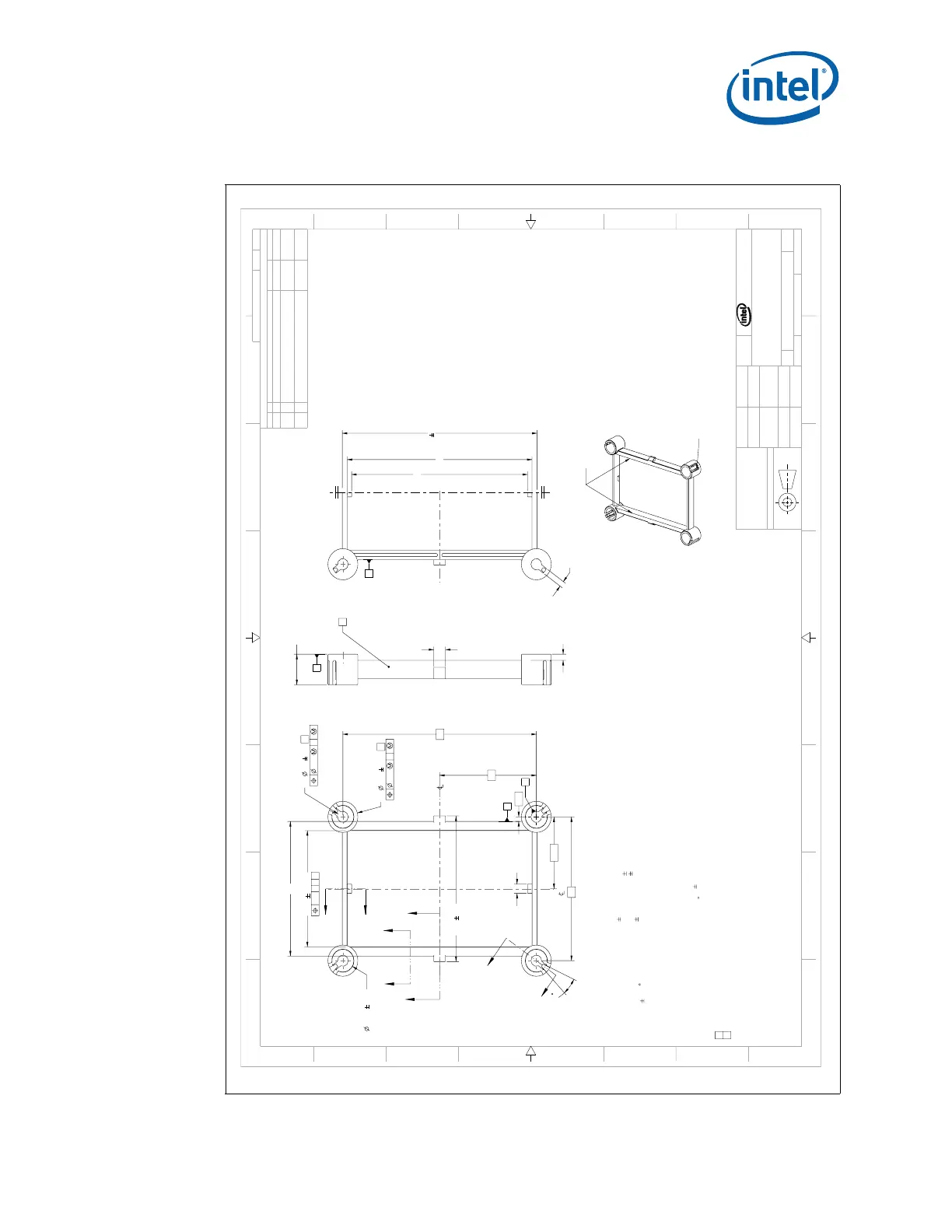

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 53

Mechanical Drawings

Figure B-8. Intel

®

3210 and 3200 Chipset Reference Thermal Solution - Bracket (1 of 2)

8 7 6 5 4 3 2

H

G

F

E

D

C

B

A

8 7 6 5 4 3 2 1

H

G

F

E

D

C

B

A

THIS DRAWING CONTAINS INTEL CORPORAT ION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONT ENTS

MAY NOT BE DISCLOSED, REPRODUCED, DI SPLAYED OR MODIFIED, WITHOUT THE PRI OR WRITTEN CONSENT OF INTEL CORPORATION.

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPROVED

- A INITIAL DV RELEASE 03/09/07 KJC

S1-C3

S2-B7

B

REMOVED ROUNDS

CHANGED DRAFT ANGLE FROM 0.5 TO 1 DEG

03/23/07 KJC

1

PART NUMBER CHANGED FROM D92625-001;

REMOVED Z-STOP FROM SEC III; INCREASED

NUT LATCH SIZE IN SEC II

05/16/07 KJC

E11663 1 1

DWG. NO SHT. REV

DEPARTMENT

R

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

PST

TITLE

BONE TRAIL,FRAME,TOP

SIZE DRAWING NUMBER REV

A1 E11663 1

SCALE:

3

DO NOT SCALE DRAWING

SHEET

1

OF

2

SEE NOTESSEE NOTES

FINISHMATERIAL

03/12/07K.KOEPSELL

DATEAPPROVED BY

03/12/07R.AOKI

03/12/07A.VALPIANI

DATECHECKED BY

03/09/07K.CEURTER

DATEDRAWN BY

03/09/07K.CEURTER

DATEDESIGNED BY

UNLESS OTHERWISE SPECIFIED

INTERPRET DIMENSIONS AND TOLERANCES

IN ACCORDANCE WITH ASME Y14.5M-1994

DIMENSIONS ARE IN MILLIMETERS

ALL UNTOLERANCED LINEAR

DIMENSIONS ± 0.1

ANGLES ±0.5

THIRD ANGLE PROJECTION

I

I

II

II

III

III

IV

IV

60

4X 7.438 0.12

47.6 0.1

23.5

33

2X 3

4X 10

44

1.5

TYP 2

4X 1.84

63

66.4 0.018

2X 4

22.2

0.15 A H

4X

610.2 0.12

0.15 A H

4X

63.7 0.1

66

47

0.1 A H C

38

0.1

C

C

A

NOTES:

1. THIS DRAWING TO BE USED IN CONJUNCTION WITH SUPPLIED 3D DATABASE FILE. ALL DIMENSIONS AND TOLERANCES ON THIS DRAWING TAKE

PRECEDENCE OVER SUPPLIED FILE AND ARE APPLICABLE AT PART FREE, UNCONSTRAINED STATE UNLESS INDICATED OTHERWISE.

2. TOLERANCES ON DIMENSIONED AND UNDIMENSIONED FEATURES UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS.

FOR FEATURE SIZES < 10MM: LINEAR .07

FOR FEATURE SIZES BETWEEN 10 AND 25 MM: LINEAR .08

FOR FEATURE SIZES BETWEEN 25 AND 50 MM: LINEAR .10

FOR FEATURE SIZES > 50MM: LINEAR .18

ANGLES: 0.5

3. MATERIAL:

A) TYPE: ENVIRONMENTALLY COMPLIANT THERMOPLASTIC OR

EQUIVALENT UPON INTEL APPROVAL (REF. GE LEXAN 500ECR-739)

B) CRITICAL MECHANICAL MATERIAL PROPERTIES

FOR EQUIVALENT MATERIAL SELECTION:

TENSILE YIELD STRENGTH (ASTM D638) > 57 MPa

FLEXURAL YIELD STREGTH (ASTM D638) > 99 MPa

TENSILE ELONGATION AT BREAK (ASTM D638) >= 46%

FLEXURAL MODULUS (ASTM D638) 3116 MPa 10%

SOFTENING TEMP (VICAT, RATE B): 154 C

C) COLOR: APPROXIMATING BLACK, (REF GE 739)

D) REGRIND: 25% PERMISSIBLE.

5 MARK PART WITH INTEL P/N, REVISION, CAVITY NUMBER AND DATE CODE APPROX WHERE SHOWN PER INTEL MARKING STANDARD 164997

6 CRITICAL TO FUNCTION DIMENSION

7. ALL DIMENSIONS SHOWN SHALL BE MEASURED FOR FAI

8. DEGATE: FLUSH TO 0.35 BELOW STRUCTURAL THICKNESS (GATE WELL OR GATE RECESS ACCEPTABLE)

9. FLASH: 0.15 MAX.

10. SINK: 0.25 MAX.

11. EJECTOR MARKS: FLUSH TO -0.25

12. PARTING LINE MISMATCH NOT TO EXCEED 0.25.

13. EJECTION PIN BOSSES, GATING, AND TOOLING INSERTS REQUIRE INTEL'S APPROVAL PRIOR TO TOOL CONSTRUCTION.

ALL EJECTION PIN BOSSES AND GATE FEATURES SHOWN ARE FOR REFERENCE ONLY.

14. EDGES SHOWN AS SHARP R 0.1 MAX.

15. TOOLING REQUIRED TO MAKE THIS PART SHALL BE THE PROPERTY OF INTEL, AND SHALL BE PERMANENTLY MARKED

WITH INTEL'S NAME AND APPROPRIATE PART NUMBER.

16. ALL SECONDARY UNIT DIMENSIONS ARE FOR REFERENCE ONLY.

5

REV B

REMOVED ROUNDS

REV B

4X REM ROUNDS

H

Loading...

Loading...