Independent Loading Mechanism (ILM)

26 Thermal/Mechanical Specifications and Design Guidelines

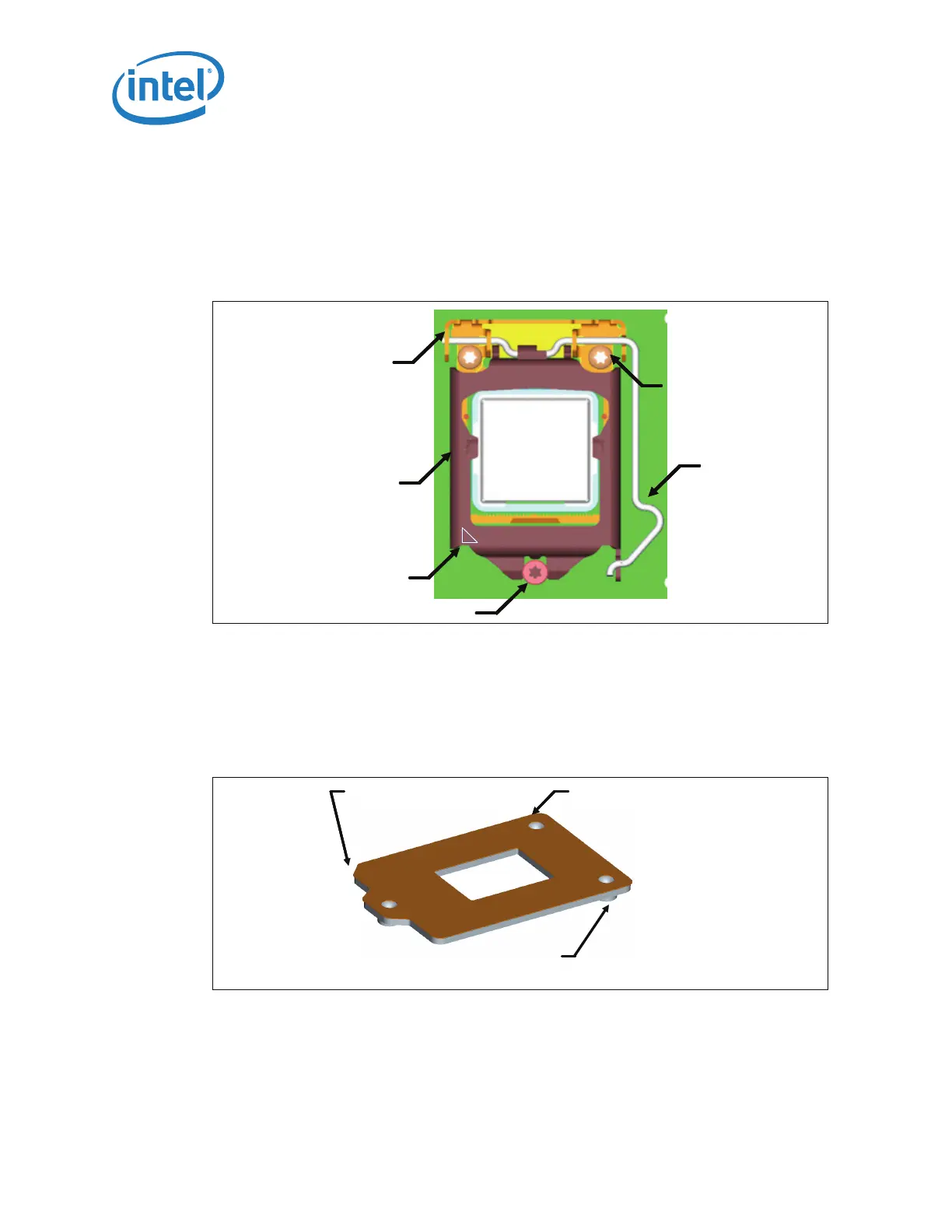

When closed, the load plate applies two point loads onto the IHS at the “dimpled”

features shown in Figure 4-1. The reaction force from closing the load plate is

transmitted to the hinge frame assembly and through the fasteners to the back plate.

Some of the load is passed through the socket body to the board inducing a slight

compression on the solder joints.

A pin 1 indicator will be marked on the ILM cover assembly.

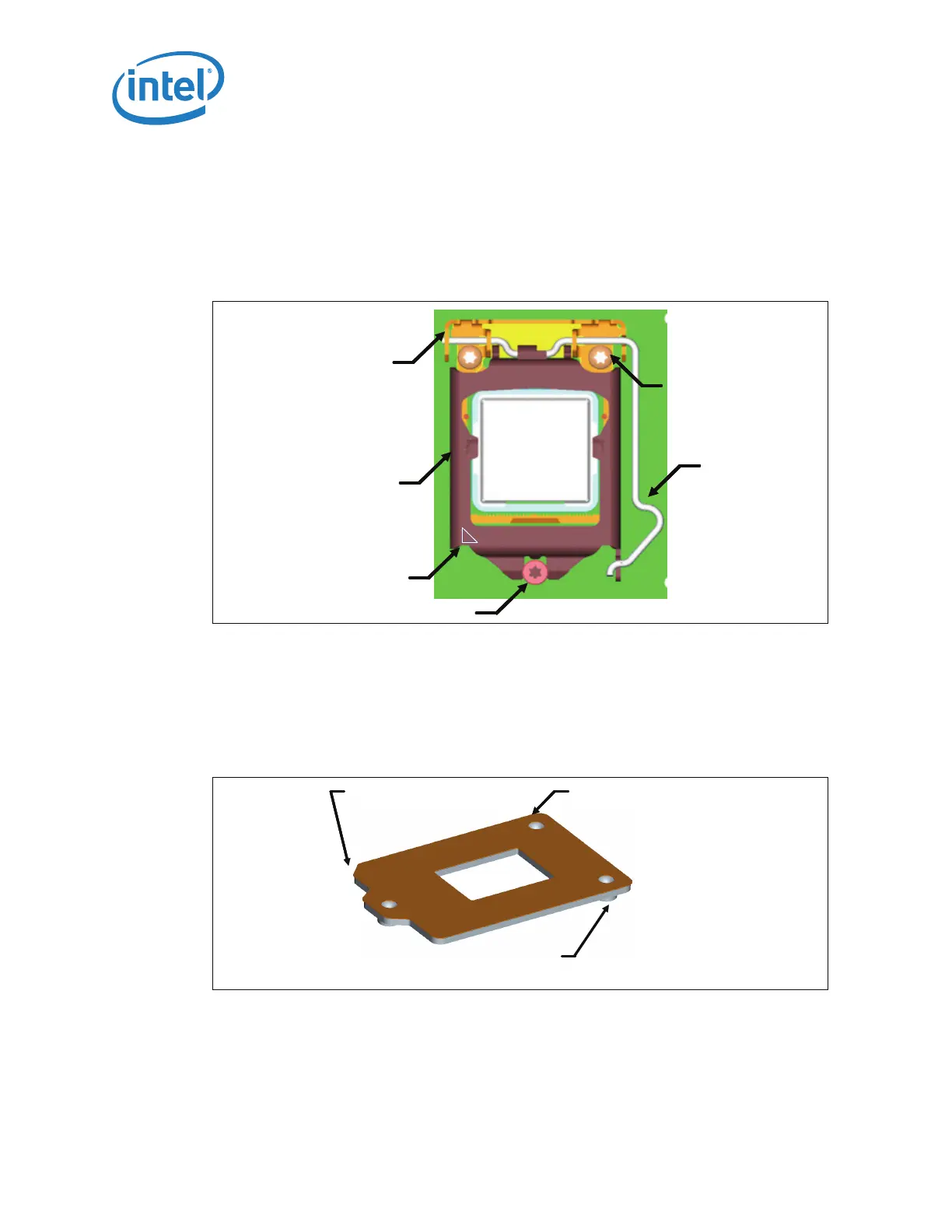

4.1.2 ILM Back Plate Design Overview

The back plate (see Figure 4-2) is a flat steel back plate with pierced and extruded

features for ILM attach. A clearance hole is located at the center of the plate to allow

access to test points and backside capacitors if required. An insulator is pre-applied. A

notch is placed in one corner to assist in orienting the back plate during assembly.

Figure 4-1. ILM Cover Assembly

Fasteners

Load

Leve

Load

Plate

Hinge /

Frame

Assy

Shoulder Screw

Pin 1 Indicator

Fasteners

Load

Leve

Load

Plate

Hinge /

Frame

Assy

Shoulder Screw

Pin 1 Indicator

Figure 4-2. Back Plate

Die Cut

Insulator

Pierced & Extruded

Thread Features

Assembly

Orientation

Feature

Die Cut

Insulator

Pierced & Extruded

Thread Features

Assembly

Orientation

Feature

Loading...

Loading...