191Intermec EasyCoder 501 – Service Manual Ed. 7

Chapter 24 Print Quality Adjustment

Factory-made Adjustments

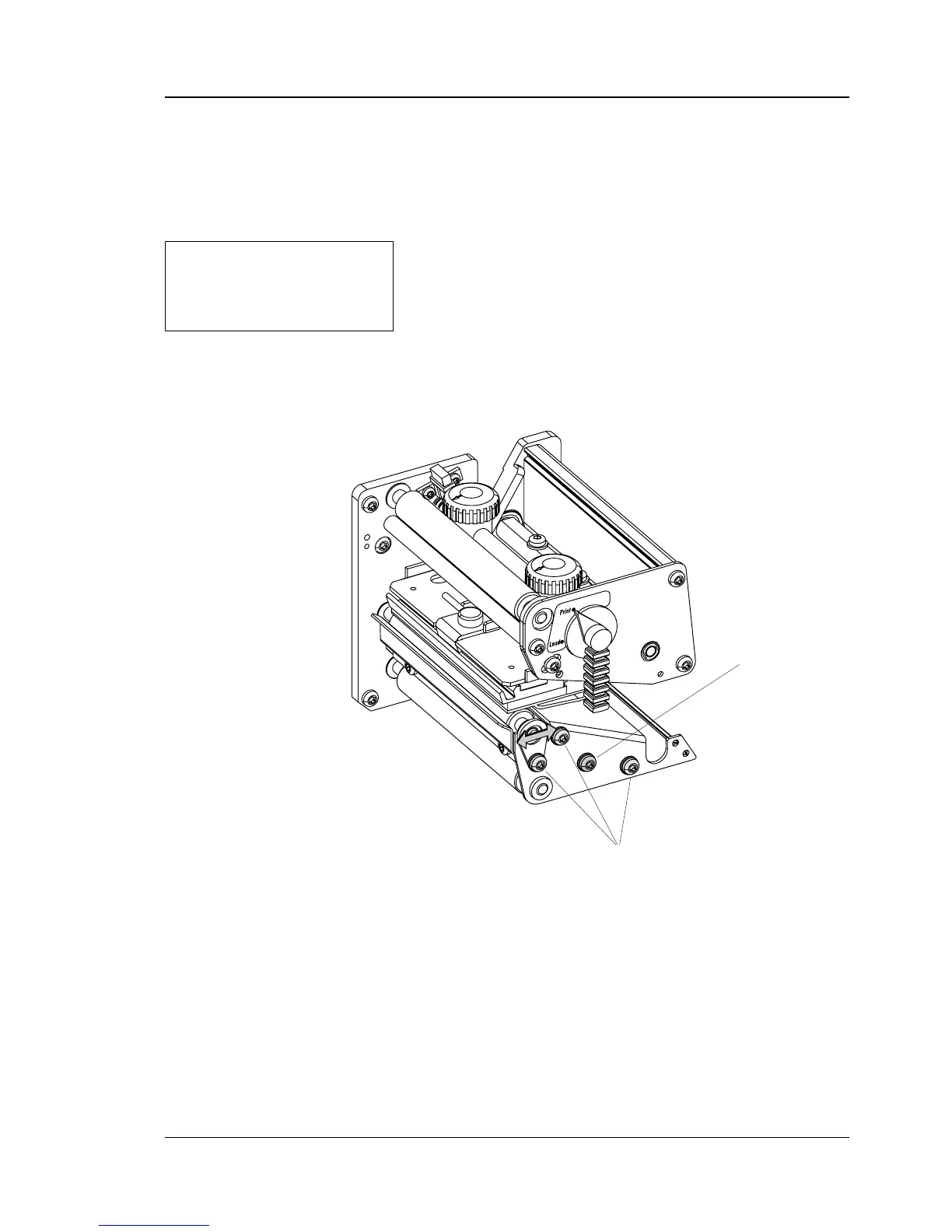

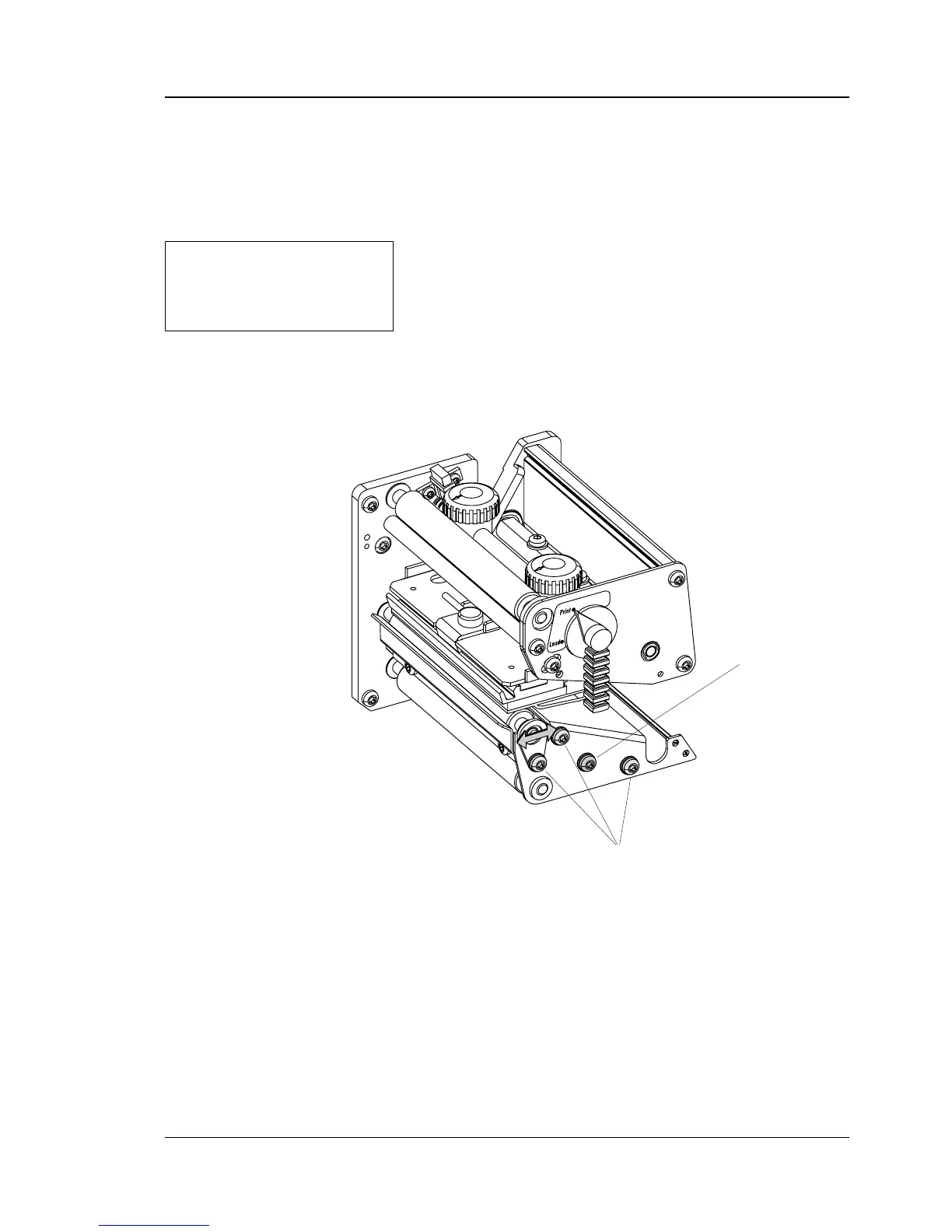

The platen roller and the liner drive roller can be adjusted, so

they become perpendicular to the inner gable of the print unit, by

moving the lower, outer gable. The gable is held by four #T20

Torx screws. Three of the screws hold the gable to the extruded alu-

minium profi le that connects the inner and outer gables, whereas

the fourth, center screw holds a dovetail-shaped plate that fi ts into

a channel in the profi le (see Chapter 8.2).

As long as the center screw is not loosened, the outer gable can be

removed and put back without the adjustment being lost. Readjust-

ment requires a fi xture and should not be attempted without such

a device.

The printhead bracket is factory-adjusted in relation to the headlift

shaft by means of oversized holes for the three screws that hold the

two parts together (see Chapter 8.8). Adjustment requires a special

fi xture and should not be otherwise attempted.

Locking Screw

(retains printhead

alignment!)

#T20 Torx Screws

CAUTION!

The ribbon save print unit has no

provision for retaining the platen roller

alignment when the outer gable is

removed, see Chapter 10.6.

24.3 Mechanical

Adjustments, cont.

Loading...

Loading...