26 of 64

Version 1.2 (08/2022) en

Translation of original operating instructions

Options and accessories

6 Options and accessories

6.1 Asynchronous drum motors with frequency inverters

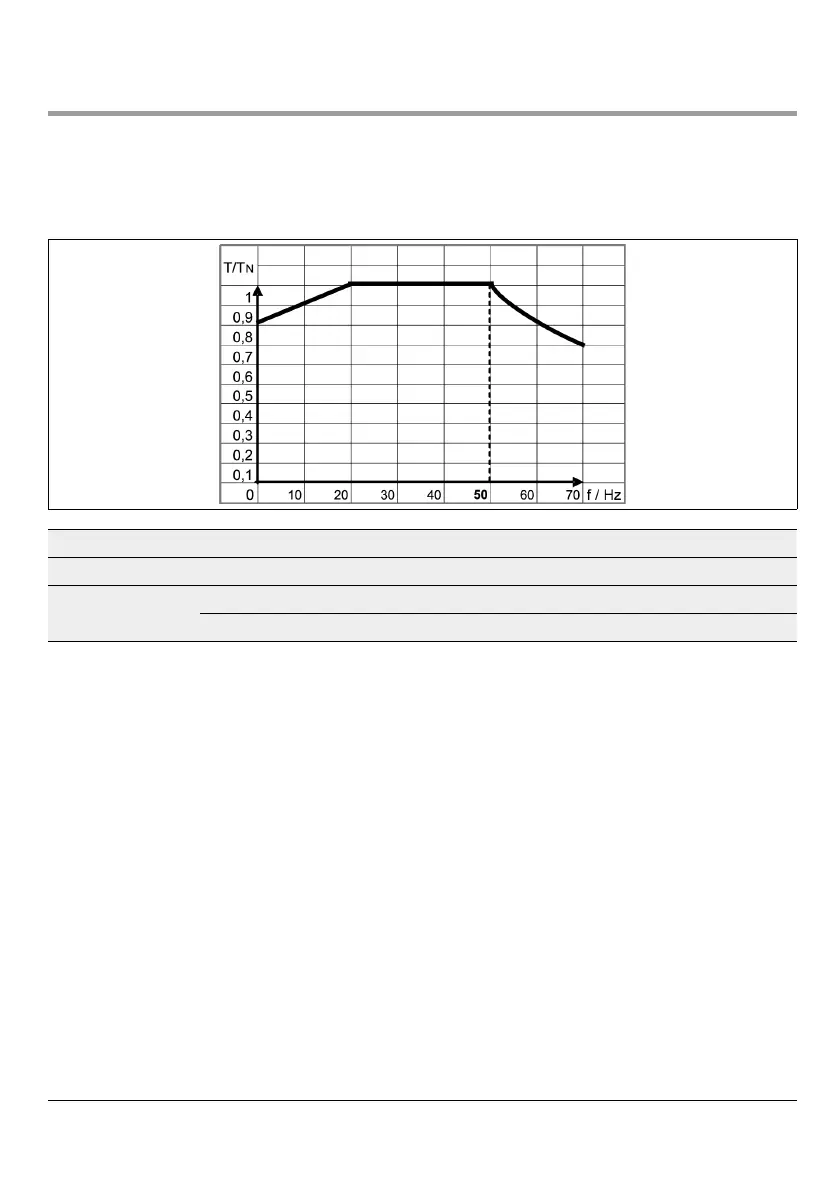

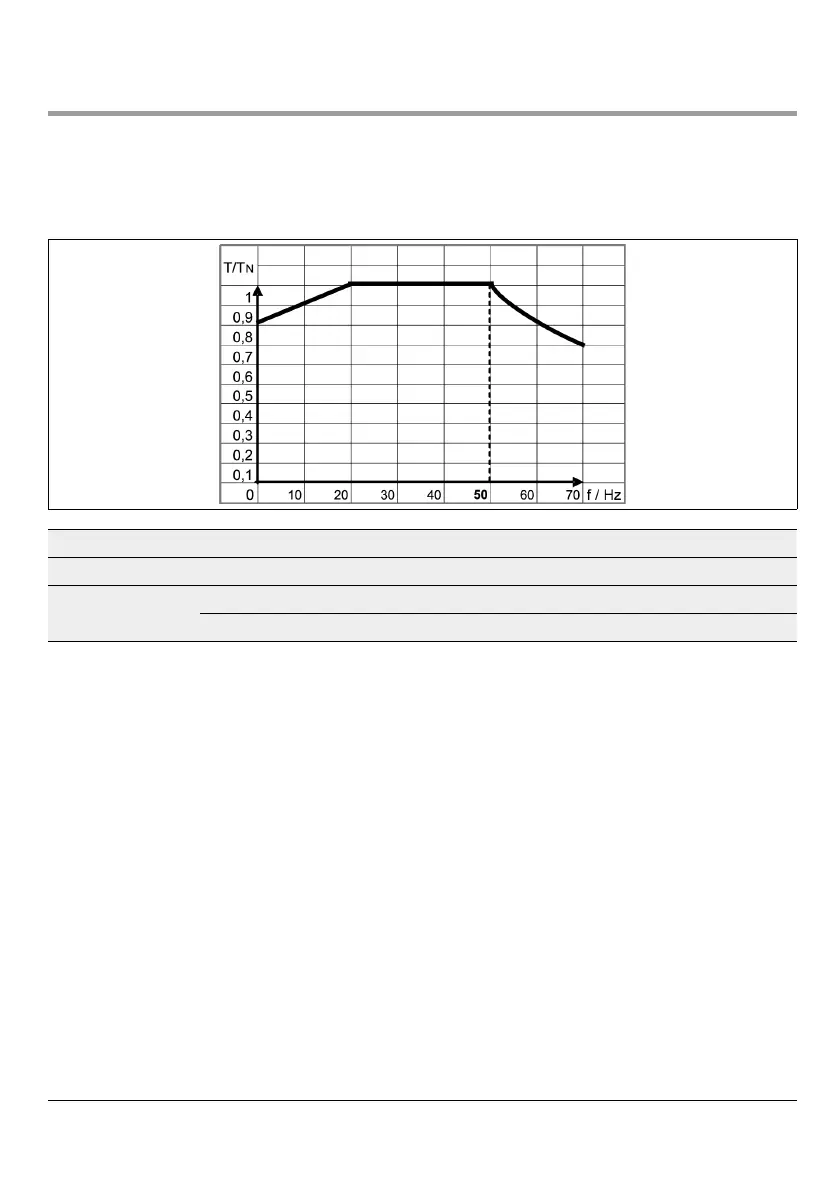

6.1.1 Torque depends on input frequency

Operatingfrequency[Hz] 5 10 15 20 25 30-50 55 60 65 70 75 80

Available motor torque in %

Rated motor

frequency

50Hz 80 85 90 95 100 100 91 83 77 71

60Hz 75 80 85 90 95 100 100 100 92 86 80 75

Value1:Basedonaratedmotorfrequencyof50Hz(50-Hzmotorsshouldbeoperatedonlyupto70Hzinthe

speedrangeundereldcontrol.)

Value2:Basedonaratedmotorfrequencyof60Hz(60-Hzmotorsshouldbeoperatedonlyupto80Hzinthe

speedrangeundereldcontrol.)

ThetorquedependencydepictedinthegureaboveisexpressedasP=Txω. With a reduced operating frequency

ofbelow20/24Hz,themotortorqueisreducedbychangingheatdissipationconditions.Thepowerlossdissipationis

aresultoftheoilquantity,incontrasttostandardventilatedmotors.Forfrequenciesstartingat80...85/95100Hz,

the curve for the output torque does not have a hyperbolic shape, but is instead replaced with a quadratic function

whichistheresultoftheeectofthepull-outtorqueandthevoltage.Theoutput/frequencycharacteristicsofmost

frequencyinverterssuppliedwith3x400V/3x460Vcanbeparameterizedto400V/87Hzinordertoconnect

motorswith230V/50Hz.Thismaycreatefurtherlossesinthemotorandleadtoitsoverheatingifthemotoris

dimensionedwithinsucientpowerreserves.

6.1.2 Frequency inverter parameters

Clock frequency:

Ahighclockfrequencyleadstoabetterutilizationfactorofthemotor.Optimumfrequenciesare8or16kHz.

Parameters such as the quality of smooth running tests (motor is running smoothly) and noise development are also

aectedpositivelybyhighfrequencies.

Loading...

Loading...