Version 1.2 (08/2022) en

Translation of original operating instructions 33 of 64

Assembly and installation

8.3 Belt assembly

Belt width / tube length

NOTICE

Risk of overheating if belt is too small!

¾ Ensure that the drum motor is operated with a conveyor belt that covers at least 70 % of the drum tube.

Fordrummotorswithlessthan70%beltcontactanddrummotorswithform-tdrivenbeltsorwithoutbelt,the

requiredoutputshouldbemultipliedby1.2.Thismustbespeciedatthetimeofordering.Ifindoubt,pleasecontact

Interroll.

8.3.1 Belt adjustment

Convex tubes center and guide the belt during regular operation. Nevertheless, the belt should be carefully aligned,

frequently checked during startup and readjusted depending on the load.

NOTICE

Adjustment errors can lead to a shortened service life as well as damages of the belt and the drum motor ball

bearings!

¾ Adjust the drum motor, belt and idler pulleys according to the instructions in this instruction manual.

1. Adjust the belt with the synchronous returning rollers and support rollers and/or (if available) with the idler

pulleys or snub pulleys.

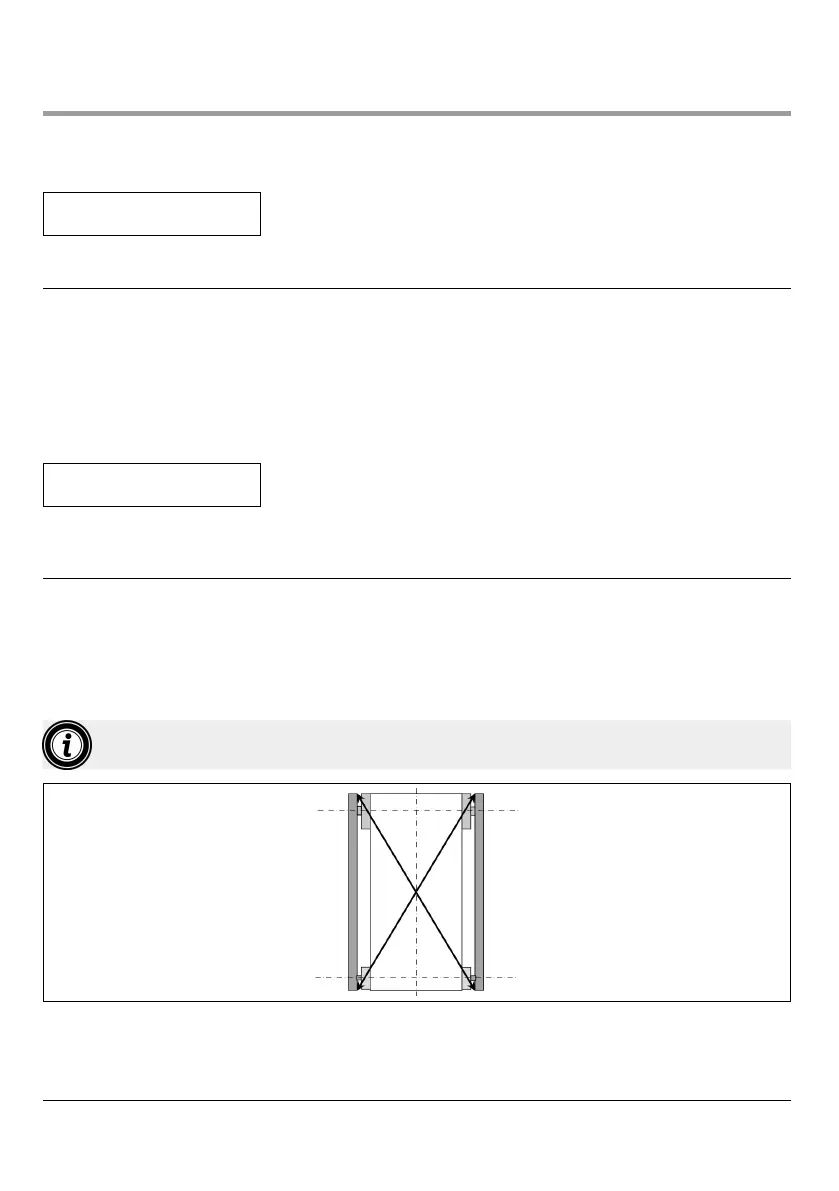

2. Check the diagonal dimensions (between the shafts of the drum motor and the shafts of the end/guide rollers

or from belt edge to belt edge).

Thedierencemustnotbegreaterthan0.5%.

The idler pulley should be cylindrical since a camber in the idler pulley could work against the camber in the

drum motor, thereby causing a belt migration.

Diagonal check

The distance between the belt and the gliding plate must not exceed 3 mm.

Loading...

Loading...