Version 1.2 (08/2022) en

Translation of original operating instructions 35 of 64

Assembly and installation

8.4 Belt tension

The following must be observed when calculating the belt tension:

• Length and width of conveyor belt

• Belt type

• The belt tension required for transporting the load

• The belt elongation required for the assembly (depending on the load, the belt elongation for the assembly should

measure between 0.2 and 0.5 % of the belt length)

• The required belt tension must not exceed the maximum belt tension (TE) of the drum motor.

The values for the belt tension and elongation are available from the belt manufacturer.

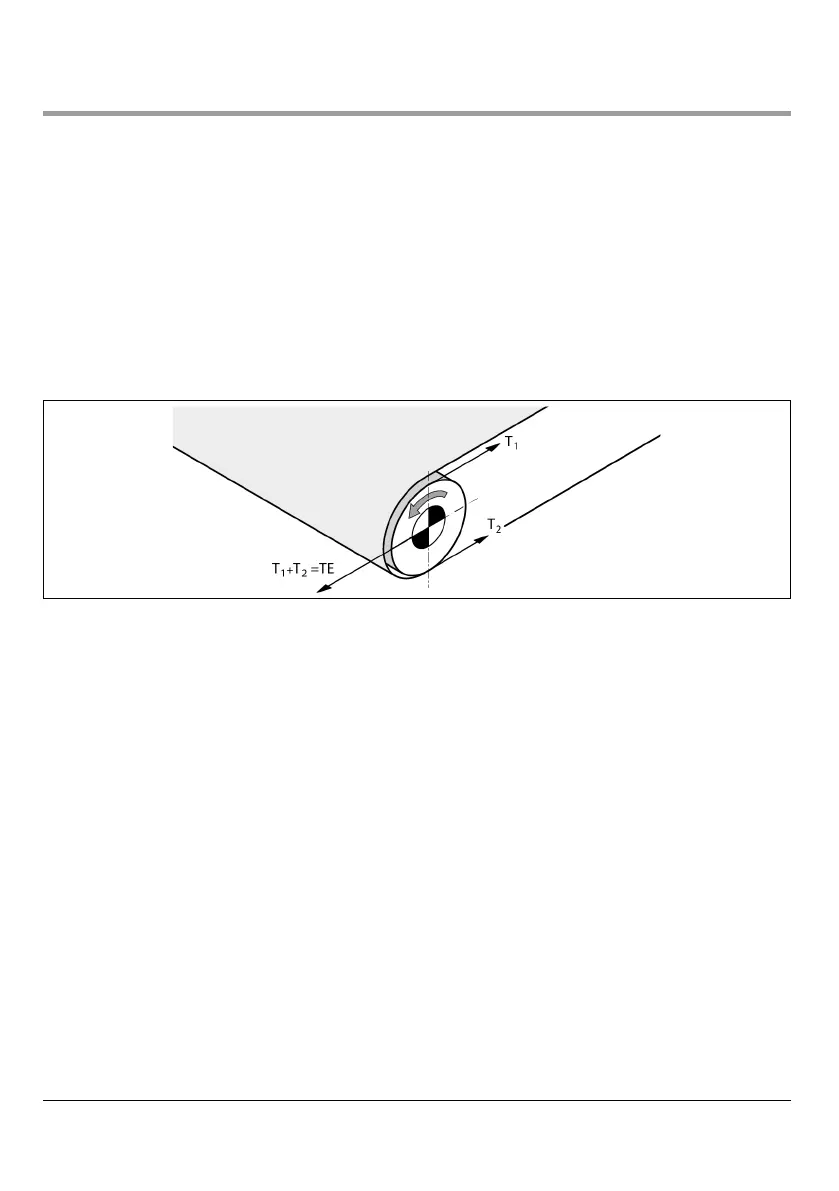

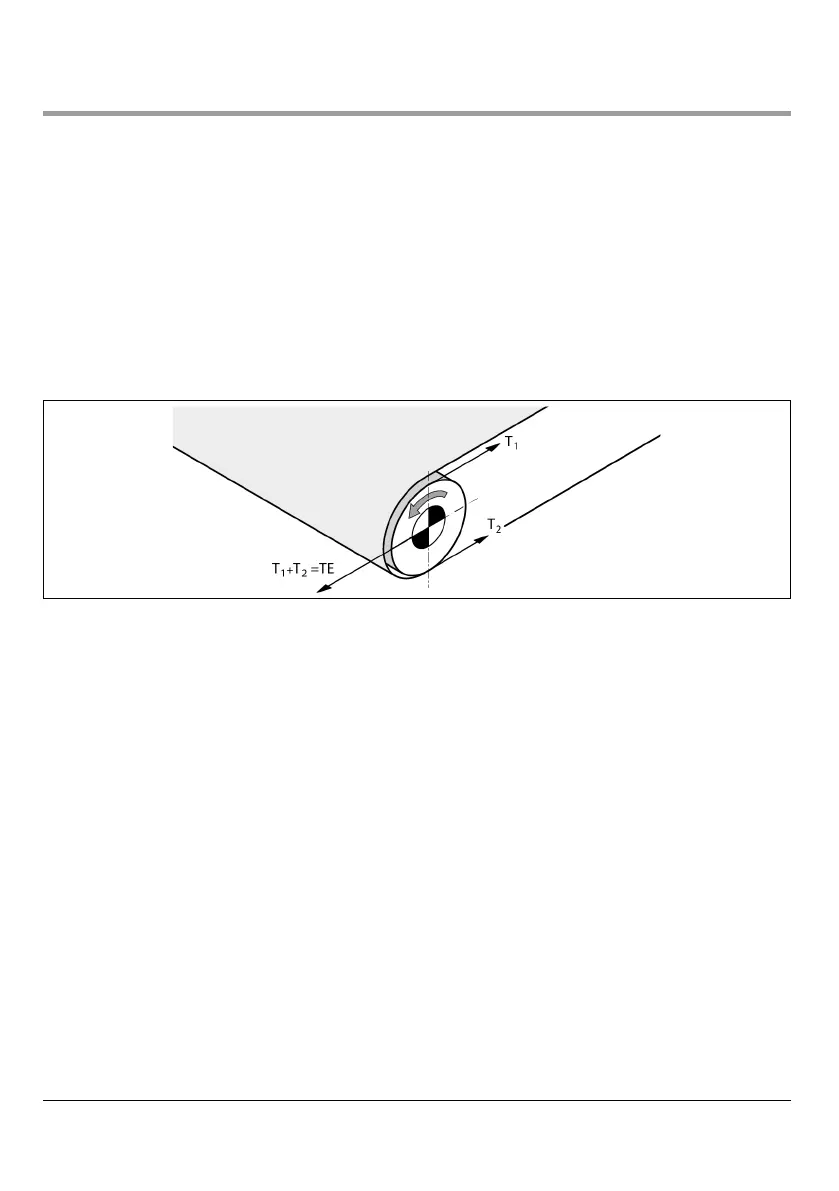

TherequiredbelttensionT1(top)andT2(bottom)canbecalculatedaccordingtothespecicationsofDIN22101or

CEMA. Based on the information from the belt manufacturer, the actual belt tension can be roughly determined by a

measurement of the belt elongation during tensioning.

The maximum permissible belt tension (TE) of a drum motor is listed in the drum motor tables of the catalog. Belt type,

belt thickness and drum motor diameter must match the information from the belt manufacturer. If the diameter of the

drum motor is too small, it can lead to damages to the belt.

If the belt tension is too strong, it can damage the shaft bearings and/or other internal components of the drum motor

and shorten the service life of the product.

8.4.1 Belt elongation

The belt tension is created by the force of the belt when it is stretched in longitudinal direction. To prevent damages to

the drum motor, it is absolutely necessary to measure the belt elongation and to determine the static belt tensioning

force.Thecalculatedbelttensionmustbeequaltoorlowerthanthevaluesspeciedinthedrummotortablesofthe

catalog.

Loading...

Loading...