Version 1.2 (08/2022) en

Translation of original operating instructions 31 of 64

Assembly and installation

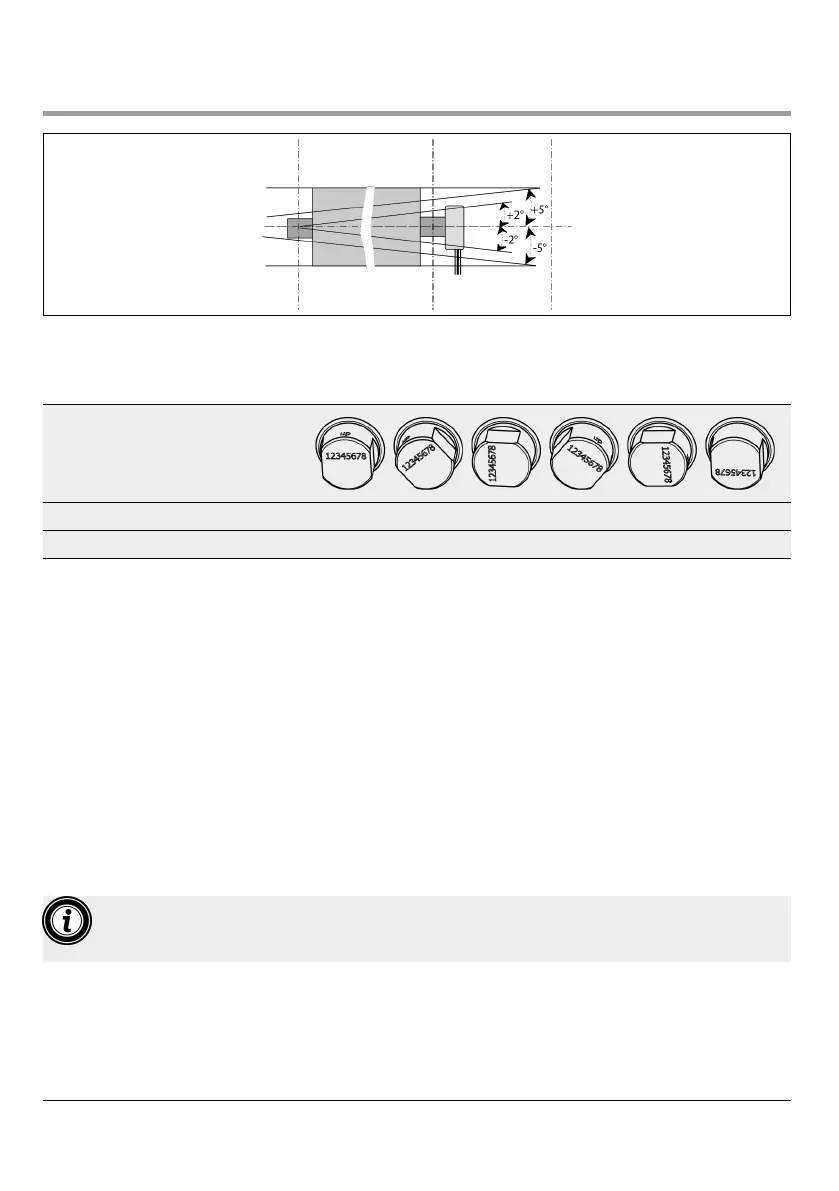

Position of the drum motor

Alldrummotorsareidentiedbytheserialnumberononeendoftheshaft.TheDLseriescanbeinstalledinany

orientation.

Motor type/mounting position 0° -45° -90° 45° 90° 180°

DL 0080 / DL 0113 √ √ √ √ √ √

8.2.2 Installing the motor with mounting brackets

Themountingbracketsmustbesucientlyrobusttowithstandthemotortorque.

1. Install the brackets at the conveyor or machine frame. Ensure that the drum motor is installed parallel to the

idler pulley and at a right angle to the conveyor frame.

2. Insert the shaft ends of the drum motor into the mounting brackets according to the „Mounting position” table

(see above).

3. If the shaft must be fastened to the mounting brackets (e.g. with a screw through a cross hole in the journal),

it should be done only on one side so that the other side can move in axial direction in case of thermal

expansion.

4. Ensurethatatleast80%ofthedrummotoratsareheldbythemountingbrackets.

5. Ensurethatthedistancebetweentheatsandthebracketisnotmorethan0.4mm.

6. If the drum motor is used for frequent reversing duty or for start/stop operation: Ensure that there is no gap

between key surfaces and the mounting brackets.

The drum motor can also be installed without mounting brackets. In this case, the shaft ends must be

installedintocorrespondingrecessesintheconveyorframe;theserecessesmustbereinforcedinsuchaway

that they meet the aforementioned requirements.

Loading...

Loading...