Version 1.2 (08/2022) en

Translation of original operating instructions 49 of 64

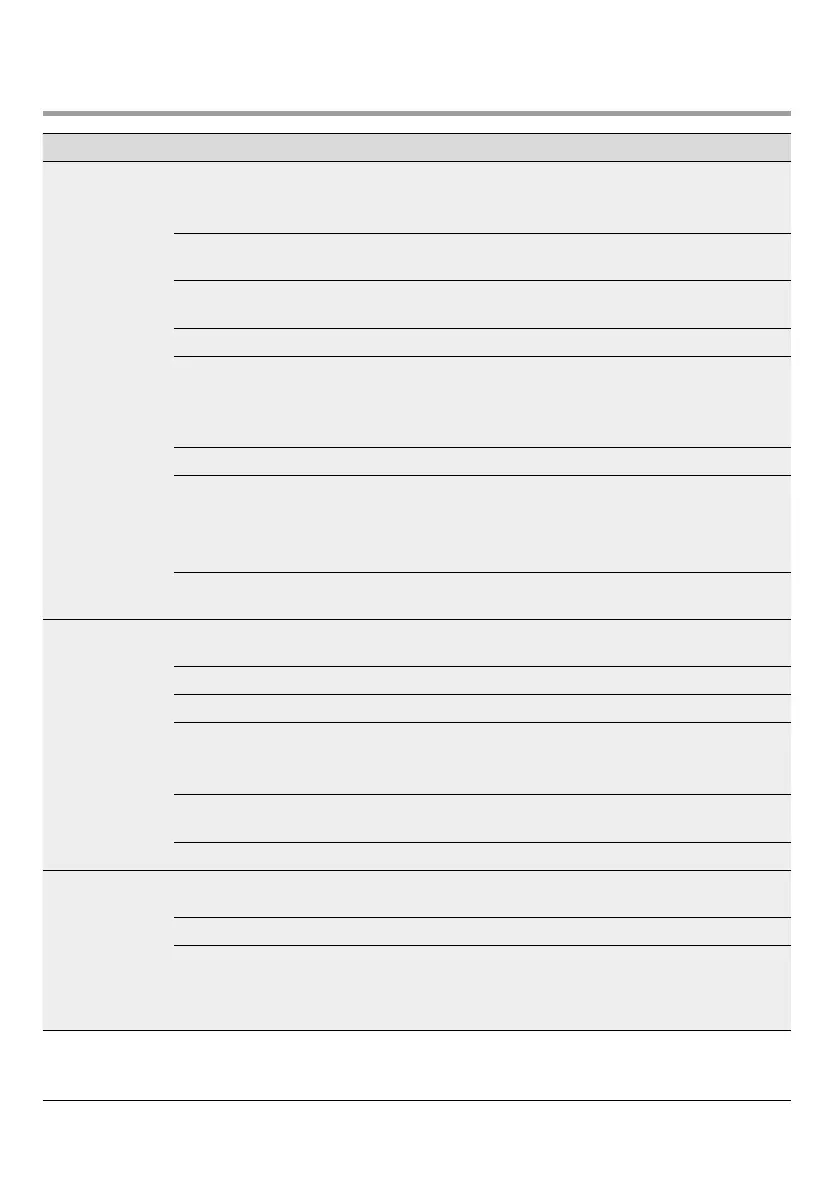

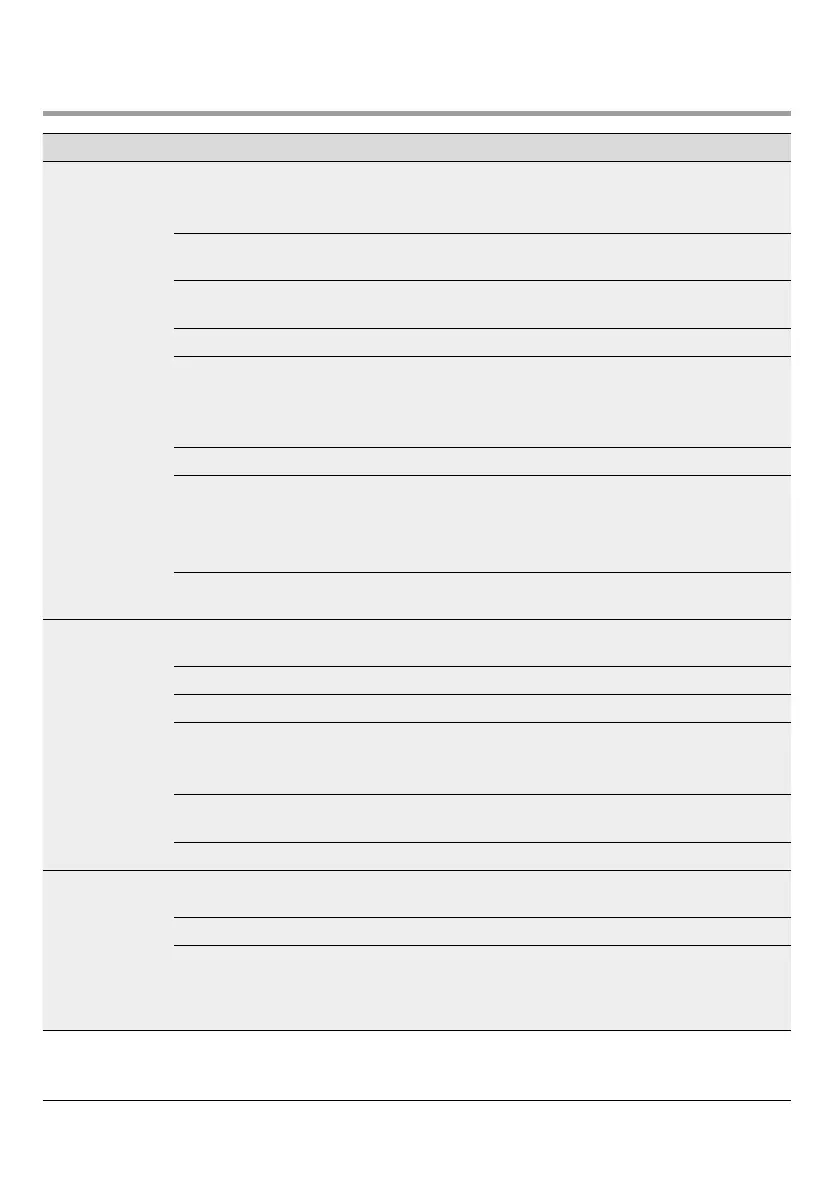

Troubleshooting

Fault Possible cause Remedy

Motor heats up

during regular

operation

Overload of drum motor Check rated current for overload.

Ensure that the motor is not rubbing against the conveyor belt

frame.

Ambient temperature

above 40 °C

Check ambient temperature. If the ambient temperature is too

high, install a cooling unit. Contact the local Interroll dealer.

Excessive or frequent

stops/starts

Do not use DL series motors for start-stop operation.

Belt tension too high Check belt tension and reduce as necessary.

Motor is not suitable for

the application

Checkwhethertheapplicationmeetsthespecicationsofthe

drum motor.

Use special reduced-power motors for operation with link belts or

without belts.

Coating too thick Replace coating or contact the local Interroll dealer.

Incorrect voltage supply Check the voltage supply.

For 1-phase motors, ensure that the correct starting or running

capacitors are used.

For 3-phase motors, ensure that no phase has failed.

Incorrect settings at

frequency inverter

Check whether the frequency inverter settings meet the

specicationsofthedrummotorandchangethem,ifnecessary.

Loud noise of

drum motor

during regular

operation

Incorrect settings at

frequency inverter

Check whether the frequency inverter settings meet the

specicationsofthedrummotorandchangethem,ifnecessary.

Loose motor mount Check motor mount, shaft tolerances and fastening screws.

Belt tension too high Check belt tension and reduce as necessary.

Wrong/incorrectprole

between drum shell and

belt

Ensurethatbeltanddrumprolematchandarecorrectly

connected. Replace as needed.

Observe belt manufacturer’s installation guidelines.

Drum motor incorrectly

mounted

Check the mounting position for that serial number.

An outer conductor failed Check connection, check power supply.

Drum motor

vibrates heavily

Incorrect settings at

frequency inverter

Check whether the frequency inverter settings meet the

specicationsofthedrummotorandchangethem,ifnecessary.

Loose motor mount Check motor mount, shaft tolerances, and fastening screws.

Drum motor runs

unevenly

Checkwhetherthespecicationsofthedrummotorcontainstatic

or dynamic balancing and adjust the motor. Single-phase motors

naturally do not run completely evenly and, for this reason, are

louder and vibrate more than three-phase motors.

Loading...

Loading...