54 of 64

Version 1.2 (08/2022) en

Translation of original operating instructions

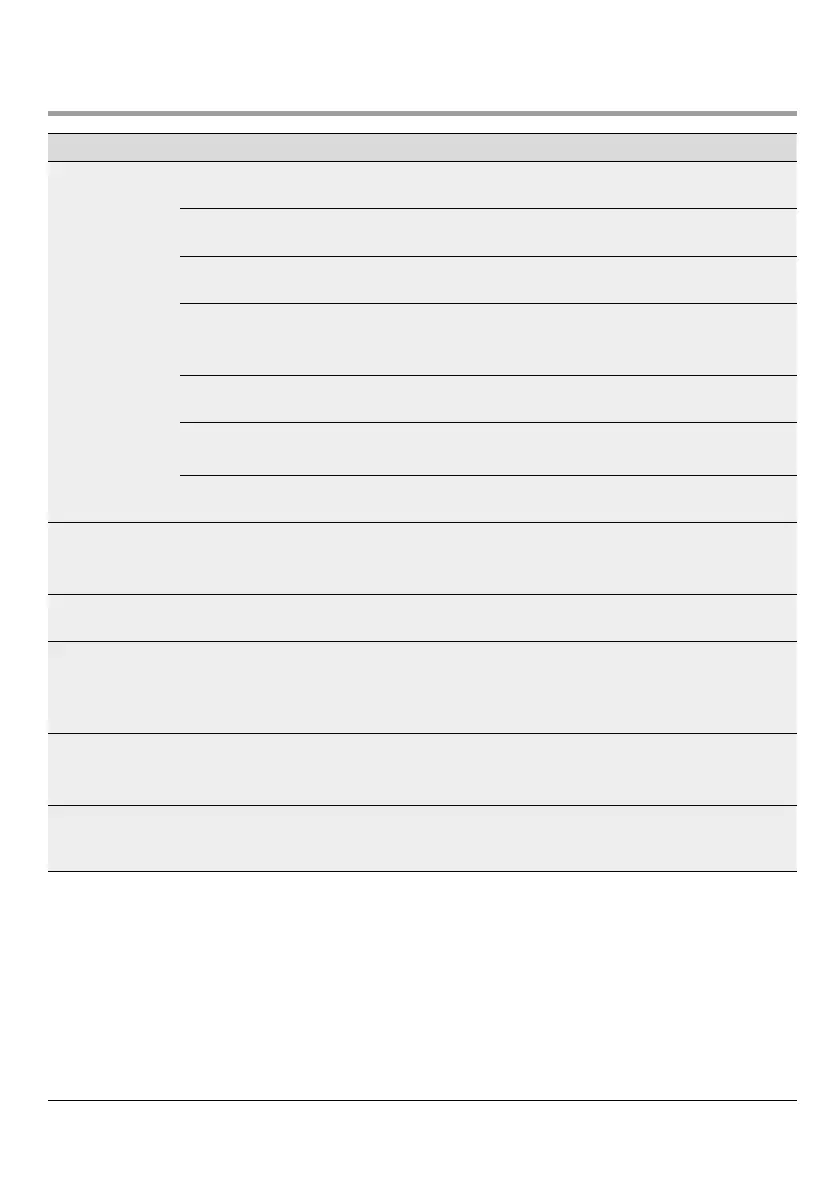

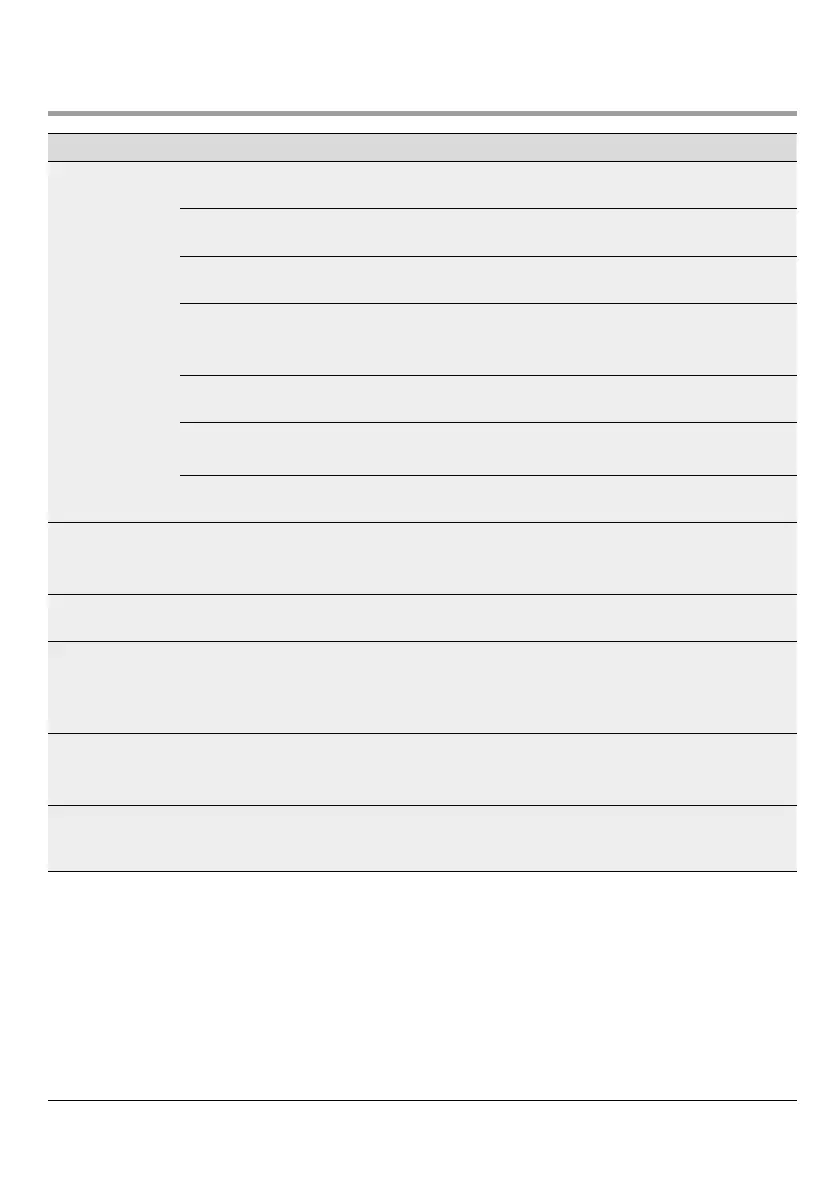

Troubleshooting

Fault Possible cause Remedy

Cap bearing

failed

Overload Checkwhethertheloadoftheapplicationmeetsthespecications

of the drum motor.

Impact load Checkwhethertheloadoftheapplicationmeetsthespecications

of the drum motor.

Belt tension too high Check whether the belt is tensioned too much. Reduce belt tension

as necessary.

Poor lubrication Check oil level and installation of drum motor.

With vertical mounting or if the motor is tilted by more than 5° (2°

forDL0113),checkmotorspecicationsofdrummotor.

Load or incorrect

adjustment of shaft

Check whether screws have been overtightened and whether

frame or motor mount are incorrectly adjusted.

Shaft seal damaged/

worn

Check for external contamination.

Contact the local Interroll dealer.

Loose or tight seating of

bearing on shaft

Contact the local Interroll dealer.

Gear box failure Overload/impact load or

regular wear

Checkwhethertheloadoftheapplicationmeetsthespecications

of the drum motor.

Check service life.

Rotor bearing

worn/ failed

Poor lubrication Check correct oil type and oil level.

Rotor drive worn

or teeth broken

o

Very high startup torque Checkwhethertheloadoftheapplicationmeetsthespecications

of the drum motor.

Check oil, maximum number of stops/starts and permissible

starting torque.

Toothed sprocket

worn or teeth/

boltsbrokeno

Start-up under overload

and/or impact load or

while blocked

Checkwhethertheapplicationandloadmeetthespecicationsof

the drum motor.

Check whether startup is blocked.

Interim gear box

and bearing

worn/failed

Poor lubrication, or worn

gear box or bearing

Check oil level.

Check service life and tolerances of journals and drives/shafts.

Loading...

Loading...