Maintenance

4.4SafetyInspectionChecklist

IMPORTANT!

–Performthisinspectionevery12months.

Railsystem

qCheckthatallbracketsaretightenedcorrectlytotheceiling/wall.

Retighten,ifnecessary.

qCheckreinforcement.Ifnotpossible,doaloadtestwith1.5x

ratedloadfor20minutes.

qCheckandretightenendstops.

qSystemswithtrackconnections:Checkiftheconnectionhas

becomemisalignedduringuse.Re-alignifneeded.

qChecktrolleyandtraversetrolley.

qChecktrolleywheelsforsmoothmovementandabnormalnoise.

qCheckfrictionbreakadjustmentontrolleys.Adjustifnecessary.

qDoaloadtestwithratedloadthroughtheentiresystem.

qPlaceastickerwithanewdateforthenextinspection.

Railsystemwithtransitcouplingconnections:

qCheckthelockfixtures:

–securetotracking

–eachclawmovesindependently

–correctlyalignedwithtrackingslots

–noobstructionstopreventcorrectfunction

–safetyplateisfitted.

qChecktraversetrolleymountingfixtures.

qChecktrackingalignment.Re-alignifnecessary.

qFunctiontesttransitcoupling/lockfixture(10times-disable

left/rightclawx5).

qCheckthatgapbetweentrackandtransitcouplingismax.3mm.

qFunctiontestunderload(5cycleswithSafeWorkingLoad).

qCheckinlayplateisfitted(LandMrail).

Ceilinghoist

qChecksuspensionandcrosspin.

qChecksteelandplasticgearwheelsforwearanddamage.

Ifgearwheelsaredry,applygearwheelgrease.

qCheckloosestrapsensorandadjustifnecessary.

qCheckstrapsforwearanddamage.

qCheckguidecylinderandendstops.

qChecktheliftinghooks,screwsandpinsforwearanddamage.

qCheckthatastickerwithmaximumloadisplacedonthehoist.

qDoafullliftingcyclewithratedload—mustbeeffortlessand

withoutjarringsound.

qPlaceastickerwithanewdatefornextinspection.

Electricalconnections

qCheckthatallcablesareintact.

qCheckforruptureoncablesandonisolation.

qCheckmicroswitchesforclampingandmechanicalfunction.

qCheckthechargerfordamage/function.

qCheckhandcontrolfordamageandfunction.Makesurethat

thehandcontrolisconnectedcorrectly.

qChecktheemergencystop.

qChecktheemergencylowering.

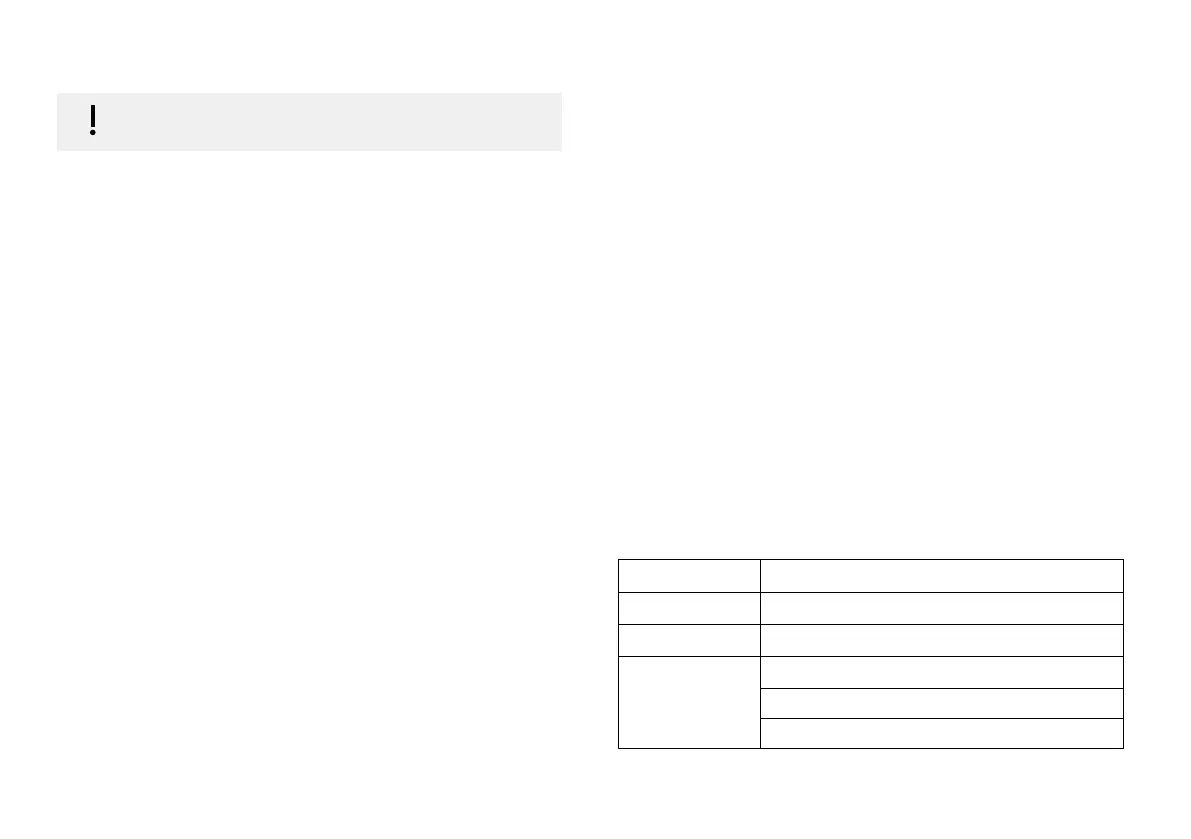

SerialNumber:

InspectionDate:

Inspectedby:

Comments:

1586747-A23

Loading...

Loading...