Goodrive300-19 series open loop vector inverter special for hosit Peripherial options and parts

-243-

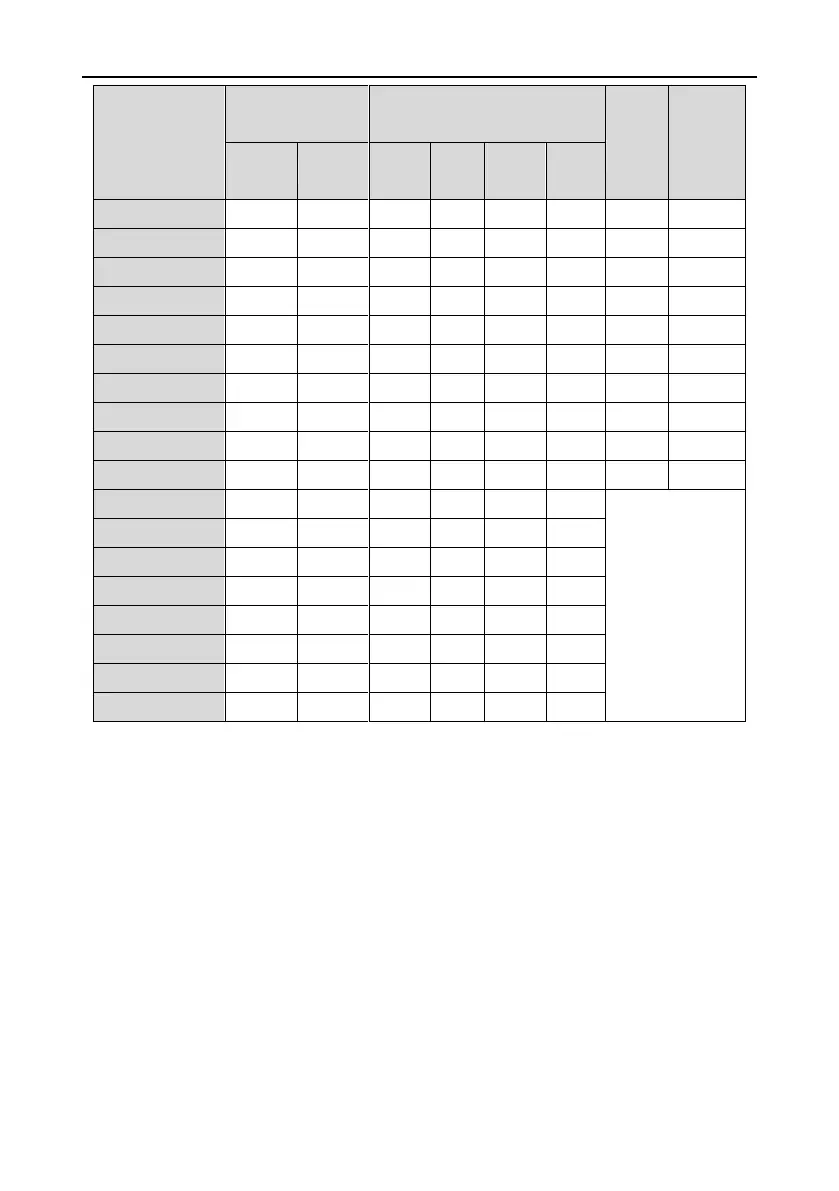

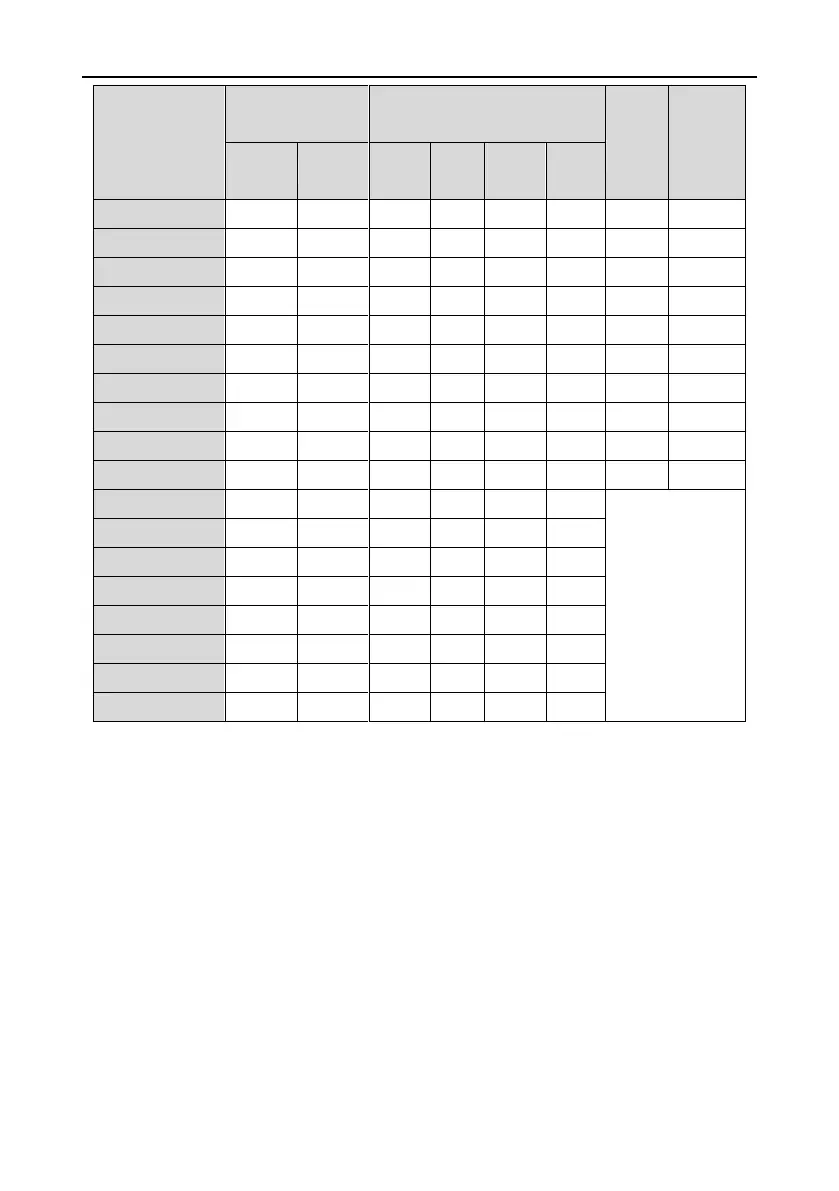

Recommended

cable size (mm

2

)

Connecting cable size (mm

2

)

It is recommended to

use wrench or

sleeve because

screw is used as

terminal.

Note:

1. It is appropriate to use the recommended cable size under 40°C and rated current. The

wiring distance should be no more than 100m.

2. Terminals P1, (+), PB and (-) connect the DC reactor and braking parts.

C.4.3 Routing the cables

Route the motor cable away from other cable routes. Motor cables of several drives can be run in

parallel installed next to each other. It is recommended that the motor cable, input power cable and

control cables are installed on separate trays. Avoid long parallel runs of motor cables with other

cables to decrease electromagnetic interference caused by the rapid changes in the drive output

voltage.

Where control cables must cross power cables make sure that they are arranged at an angle as near

to 90 degrees as possible.

Loading...

Loading...