Goodrive300-19 series open loop vector inverter special for hoist Maintenance and hardware diagnosis

-204-

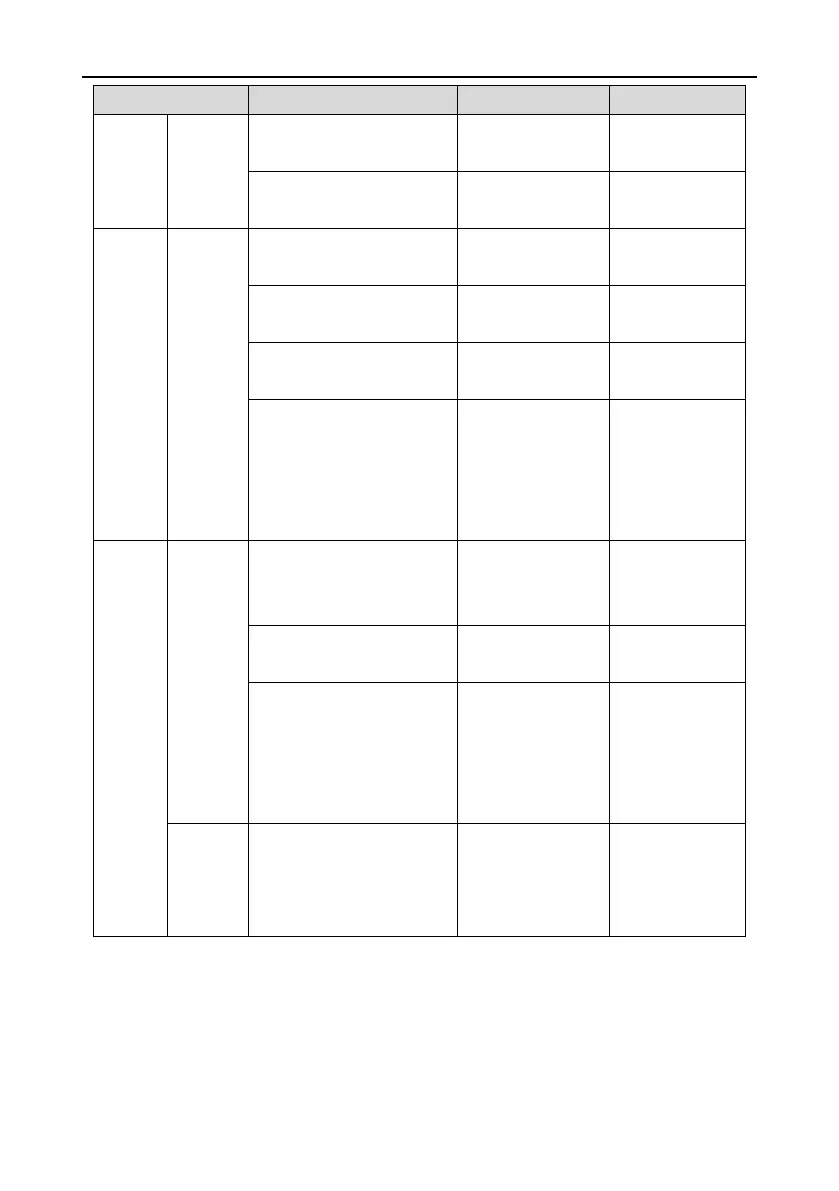

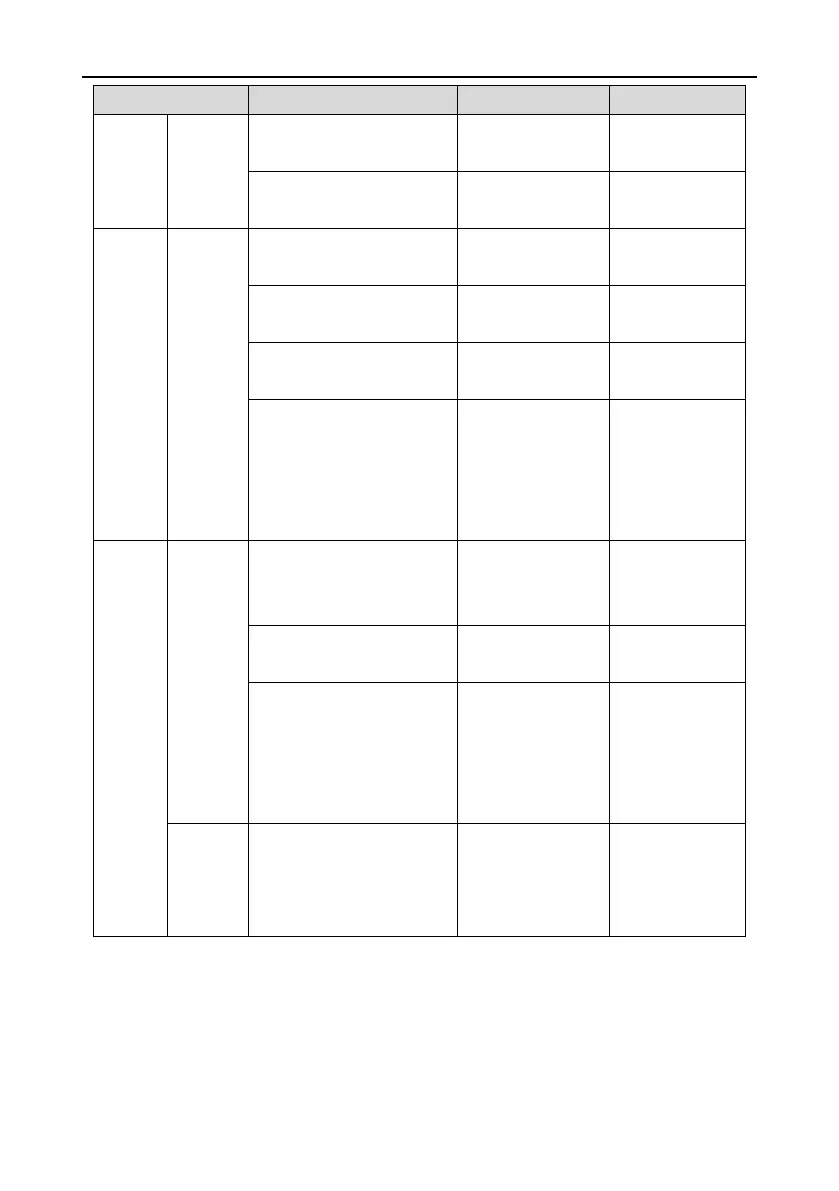

magnetic

contactor

and relay

vibration noise in the

workrooms.

Ensure the contact is in good

connection.

Ensure there are no loose

screws or contactors.

Ensure there is no smelling or

color-changing.

Smelling and visual

examination

Ensure there are no crackles,

damage, distortion or rust.

Ensure there is no leakage or

distortion to the capacitors.

Visual examination or

estimate the life time

according to the

maintenance

information

Estimate whether there is

abnormal noise and vibration.

Hearing and Visual

examination or rotate

with hand

Estimate there is no loose

screws.

Ensure there is no

color-changing caused by

overheat.

Visual examination or

estimate the life time

according to the

maintenance

information

Ensure whether there is no

stuff or foreign objects in

cooling fan, air inlet and air

vent.

Consult the local service representative for more details on the maintenance. Visit the official website.

9.3 Cooling fan

The inverter’s cooling fan has a minimum life span of 25,000 operating hours. The actual life span

depends on the inverter usage and ambient temperature.

The operating hours can be found through P07.14.

Loading...

Loading...