INVT SV-DA200 AC Servo Drive PROFINET Technical Guide V2.63

34

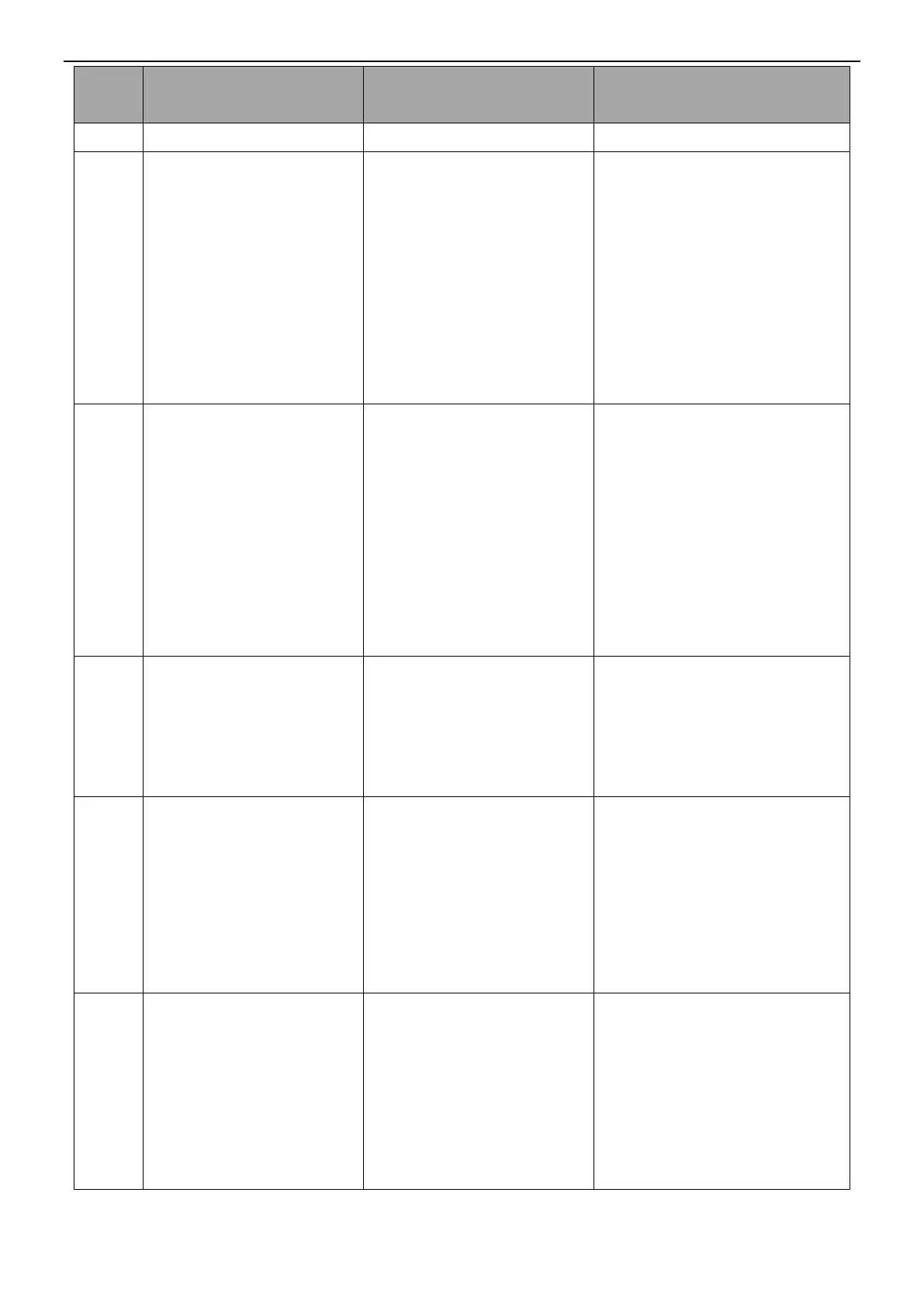

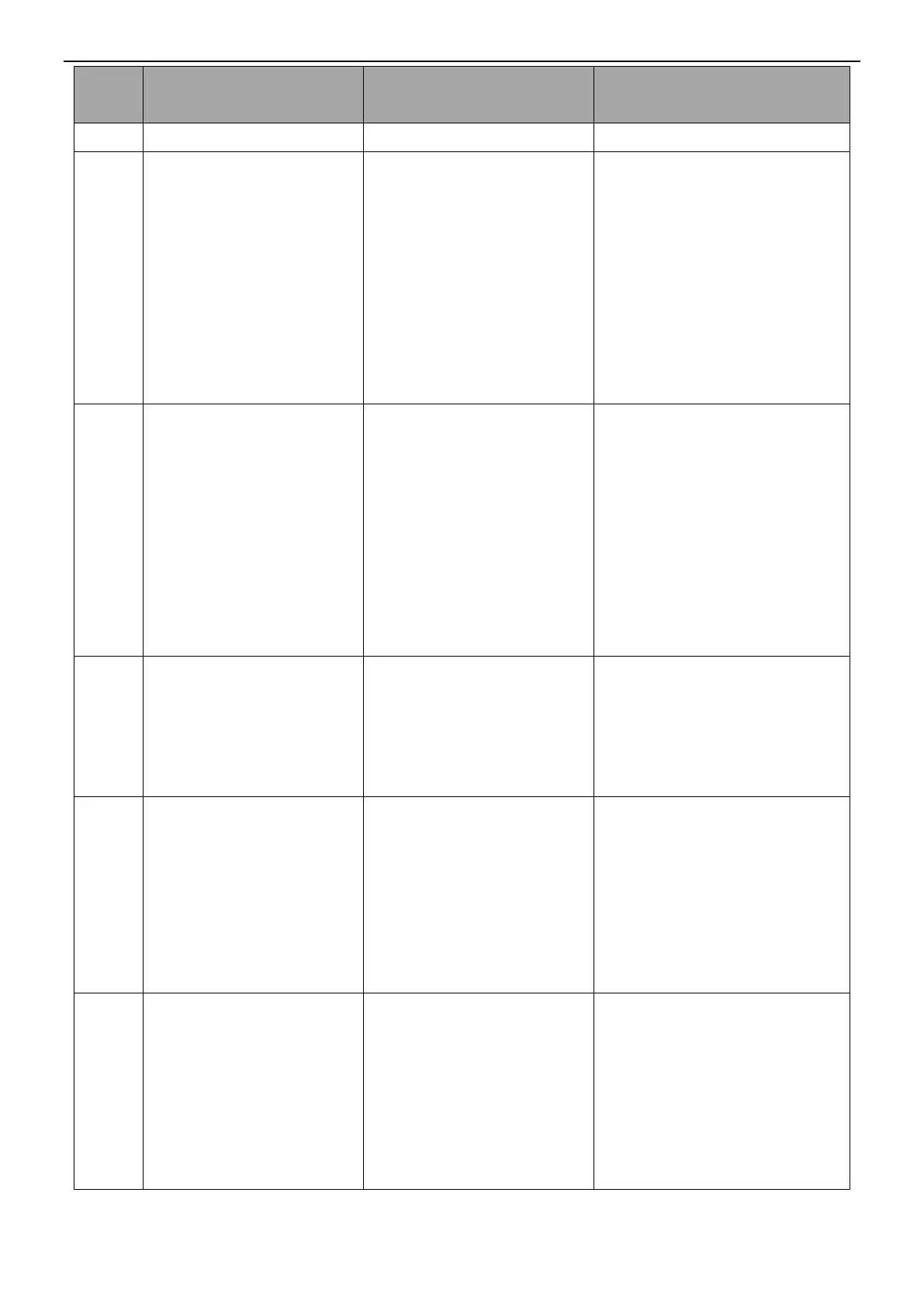

Encoder fault–Encoder

battery low-voltage alarm

When a multi-turn absolute

encoder is used, the external

battery voltage of the encoder

is between 3.0V–3.2V.

1. Ensure the encoder battery

cable is connected properly.

2. Use the multimeter to check

whether the external battery

voltage is lower than 3.2V. If yes,

replace the battery.

3. Replace the battery when the

drive power is on. Otherwise,

encoder data will be lost.

Encoder fault–Encoder

battery undervoltage fault

When a multi-turn absolute

encoder is used, the external

battery voltage of the encoder

is between 2.5V–3.2V.

1. Ensure the encoder battery

cable is connected properly.

2. Use the multimeter to check

whether the external battery

voltage is lower than 3.0V. If yes,

replace the battery.

3. Replace the battery when the

drive power is on. Otherwise,

encoder data will be lost.

Encoder fault–Encoder

overheating

The encoder feedback

temperature is higher than

the temperature threshold for

protection against

overheating.

1. Ensure the temperature

threshold for protection against

overheating is correct.

2. Stop the motor to lower the

encoder temperature.

Encoder fault–Encoder

EEPROM writing error

If the motor is used with a

communication encoder, a

communication transmission

or data check error occurs

when the drive updates data

to the encoder EEPROM.

1. Ensure encoder cables are

connected properly and eliminate

the conditions that disturb

encoder communication.

2. Make multiple writing

attempts. If the fault is reported

repeatedly, replace the motor.

Encoder fault–No data in

encoder EEPROM

If the motor is used with a

communication encoder, no

data is found in the encoder

EEPROM when the motor

attempts to read data from it

during power-on.

1. Select the motor model based

on the setting of P0.00 and

execute the operation of writing

data to the encoder EEPROM

through P4.97.

2. Mask this fault by setting

P4.98. The motor parameters in

Loading...

Loading...