SV-DA200 series AC servo drives Faults and solutions

‐104‐

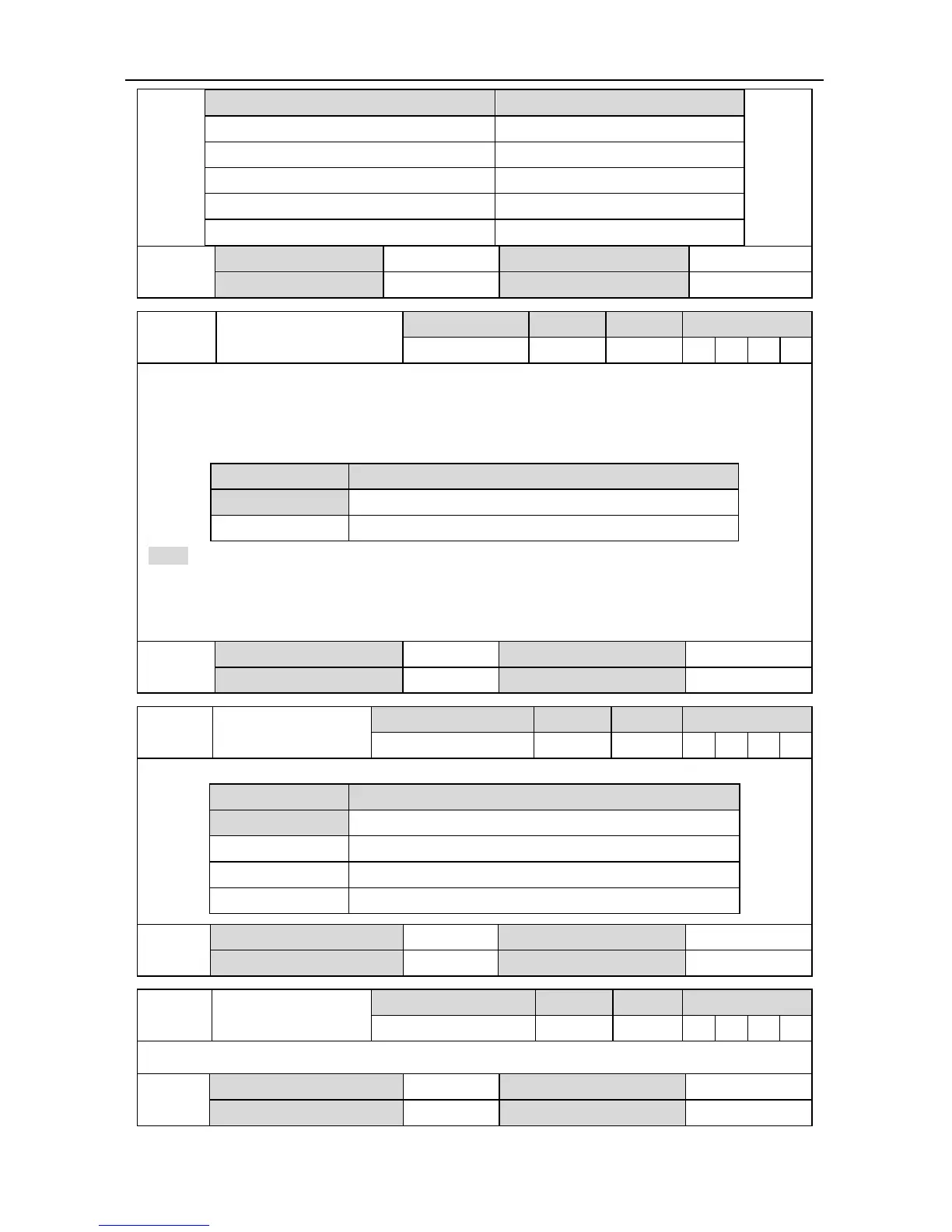

Mechanical structure Rigidity set

Big handling, transmission equipment 0~13

Belt drive mechanism 5~16

Ball screw + Belt drive 5~16

Manipulator 15~22

Direct ball screw or rigid bodies 18~25

P1.03

Data size 16bit Data format DEC

Modbus address 1206,1207 CANopen address 0x2103,0x00

P1.04

Inertia offline automatic

estimation

Setting range Default Unit Available mode

0~1 0 - P S T F

The load inertial ratio of motor rotation inertia can be gained by setting this parameter. After

setting the inertia identification, the motor will run 6 cycles to carry out the inertia identification.

In each cycle, the motor will run at the mode of P1.05, the maximum rotation cycles are

determined by P1.06 and the ACC command time is determined by P1.07.

Setting value Function

[0] Inertia identification switch off

1 Inertia identification switch on

Note:

1. The motor speed during identification will be faster if the value of P1.06 and P1.07 are bigger.

2. Refer to chapter 10.1 if the drive reports Er25-7.

3. This parameter is invalid in the servo enabling state.

P1.04*

Data size 16bit Data format DEC

Modbus address 1208,1209 CANopen address 0x2104,0x00

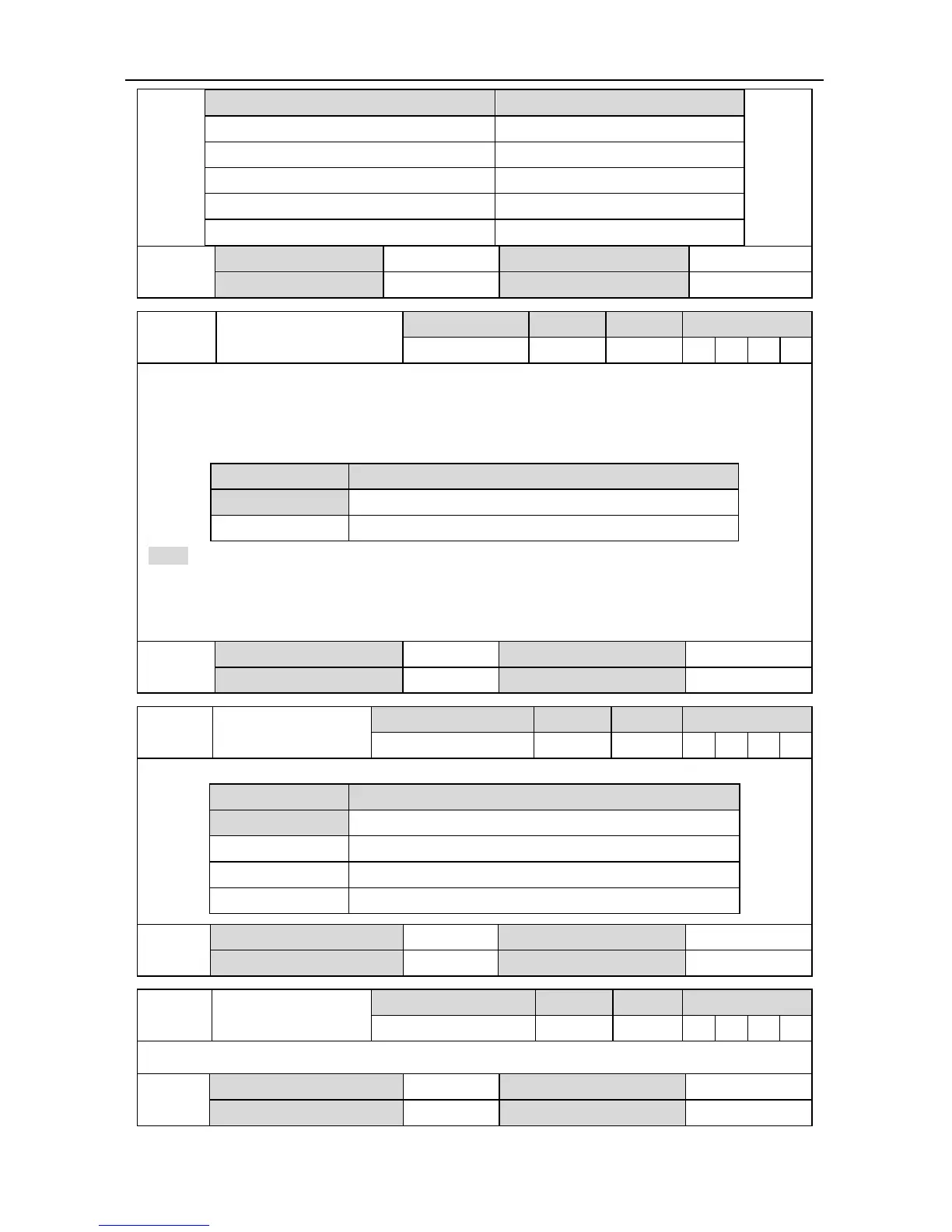

P1.05

Operation mode of

inertia identification

Setting range Default Unit Available mode

0~3 0 - P S T F

This parameter is used to set the operation mode of inertia identification.

Setting value Function

[0] Forward rotation and then reverse rotation

1 Forward rotation

2 Reverse rotation

3 Reverse rotation and then forward rotation

P1.05

Data size 16bit Data format DEC

Modbus address 1210,1211 CANopen address 0x2105,0x00

P1.06

Movable range of

inertia identification

Setting range Default Unit Available mode

0.2~20.0 2.0 r P S T F

In the position mode, this parameter is used to limit the maximum circle number in each cycle.

P1.06

Data size 16bit Data format DEC

Modbus address 1212,1213 CANopen address 0x2106,0x00

Loading...

Loading...