6A – 58 GENERAL ENGINE MECHANICAL

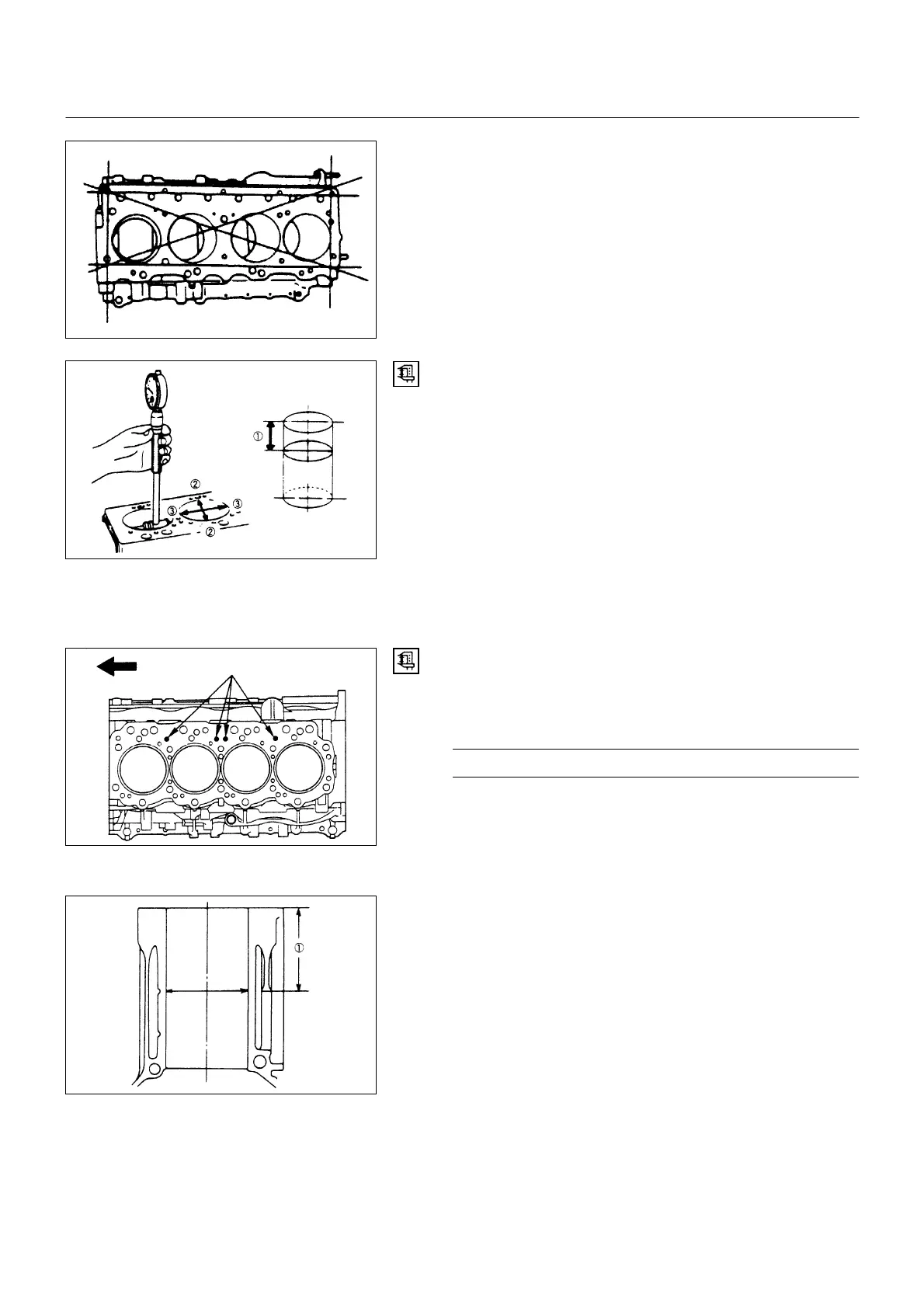

5. Use a straight edge

!

and a feeler gauge

"

to

measure the four sides and the two diagonals of the

cylinder body upper face.

If the measured values exceeds the limit, the cylinder

body must be replaced.

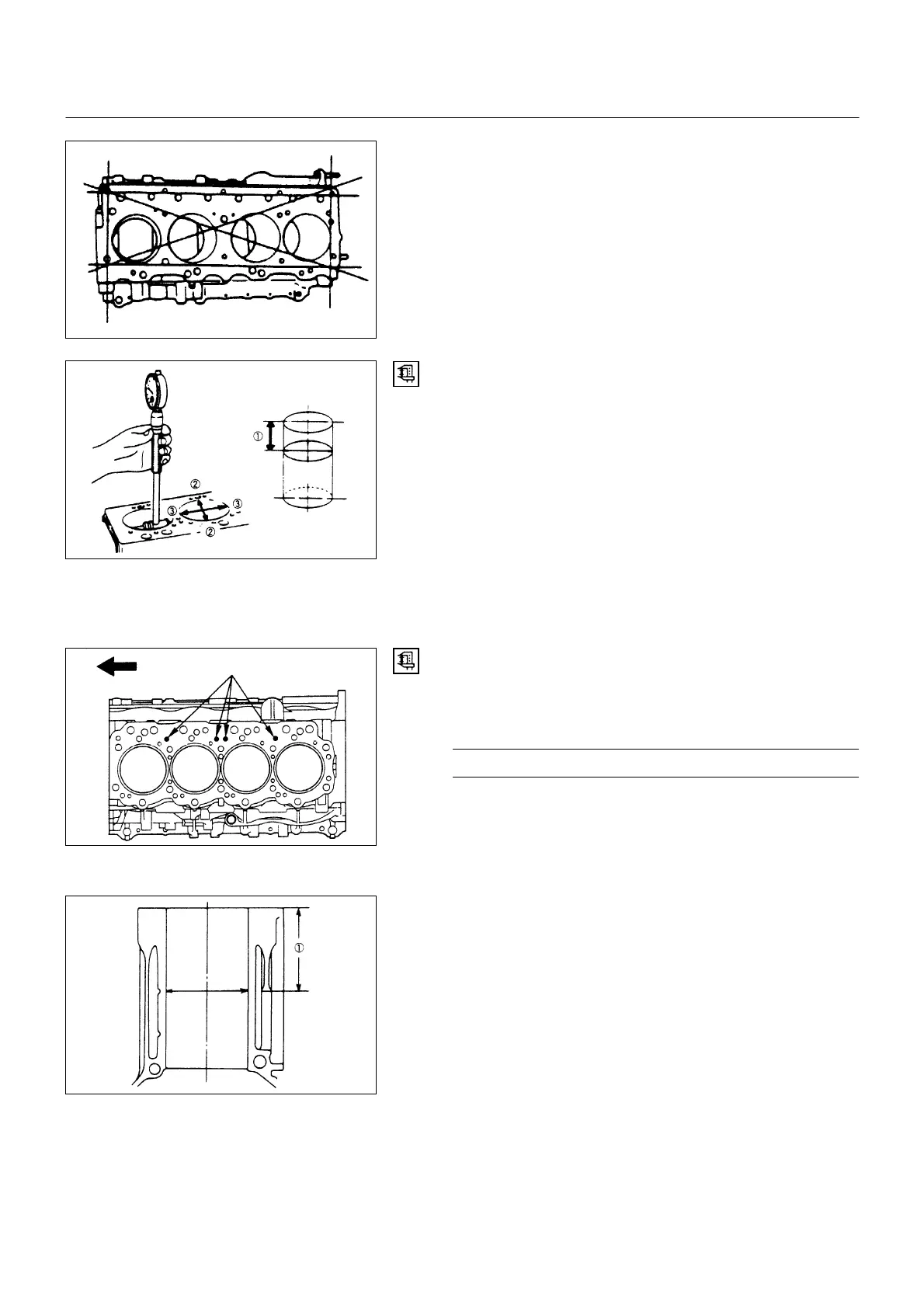

Cylinder Liner Bore Measurement

Use a cylinder indicator to measure the cylinder liner bore

at measuring point

!

in the thrust

"

-

"

and axial

#

direction of the crankshaft.

Measuring Point

!

20mm (0.79 in)

If the measured value exceeds the specified limit, the

cylinder liner must be replaced.

NOTE:

The inside of the dry type cylinder liner is chrome

plated. It cannot be rebored or honed.

If the inside of the cylinder liner is scored or

scorched, the cylinder liner must be replaced.

Cylinder Liner Grade Selection

Measure the cylinder body inside diameter and select the

appropriate cylinder liner grade.

Standard Lifting Interference mm (in)

0.01 - 0.019 (0.0004 - 0.0007)

If the cylinder liner fitting interference is too small, engine

cooling efficiency will be adversely effected.

If the cylinder liner fitting interference is too large, it will be

difficult to insert the cylinder liner into the cylinder body.

6A-58-1.tif

6A-58-2.tif

6A-58-3.tif

6A-58-4.tif

Loading...

Loading...