GENERAL ENGINE MECHANICAL 6A – 5

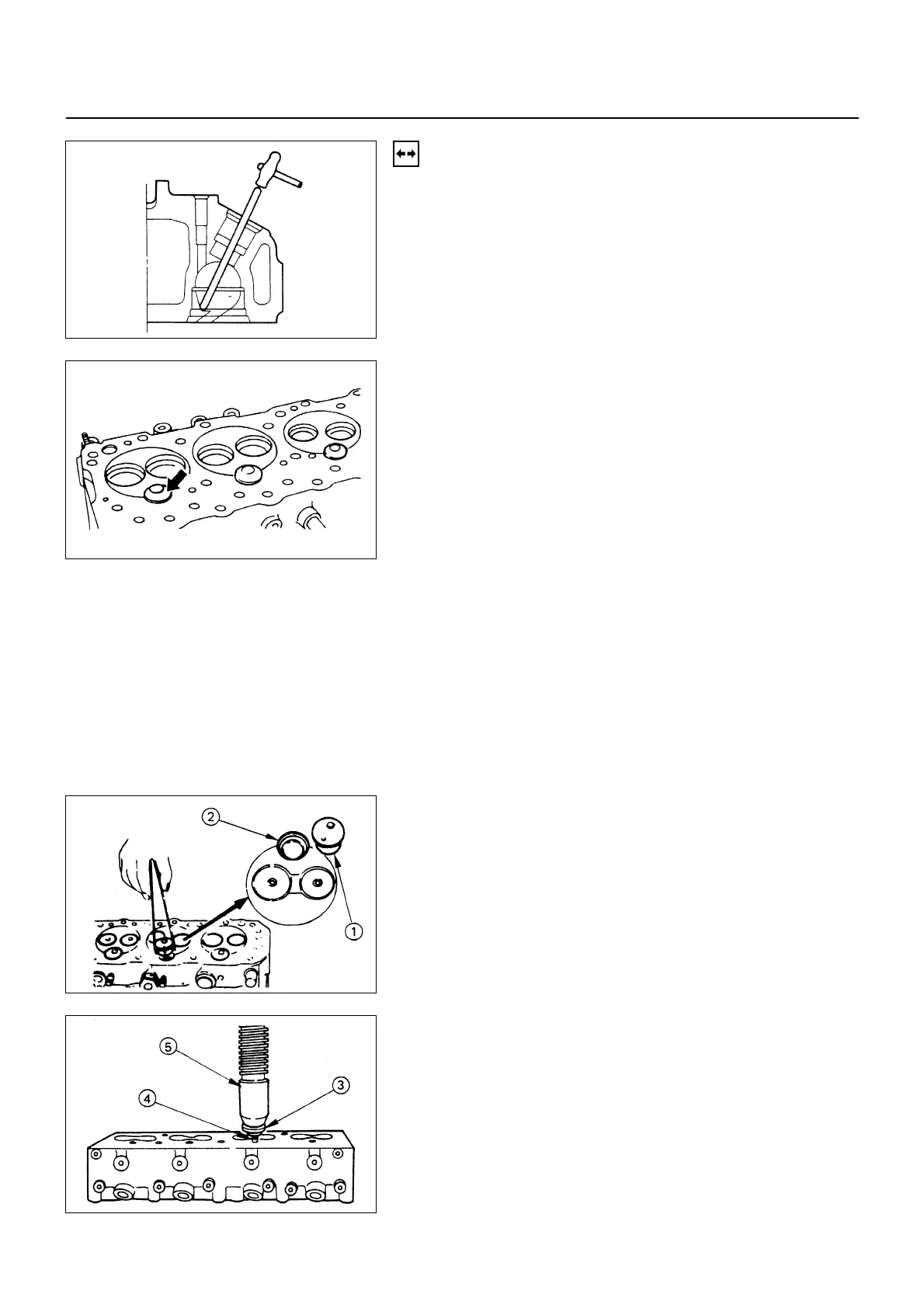

Hot plug removal (4JG2 only)

1. Insert a 3.0 - 5.0 (0.12 - 0.20.) diameter bar into the

nozzle holder fitting hole unit it makes contact with the

hot plug.

2. Lightly tap the bar with a hammer to drive the hot plug

free.

If the measured value exceeds the limit, the hot plugs

must be replaced.

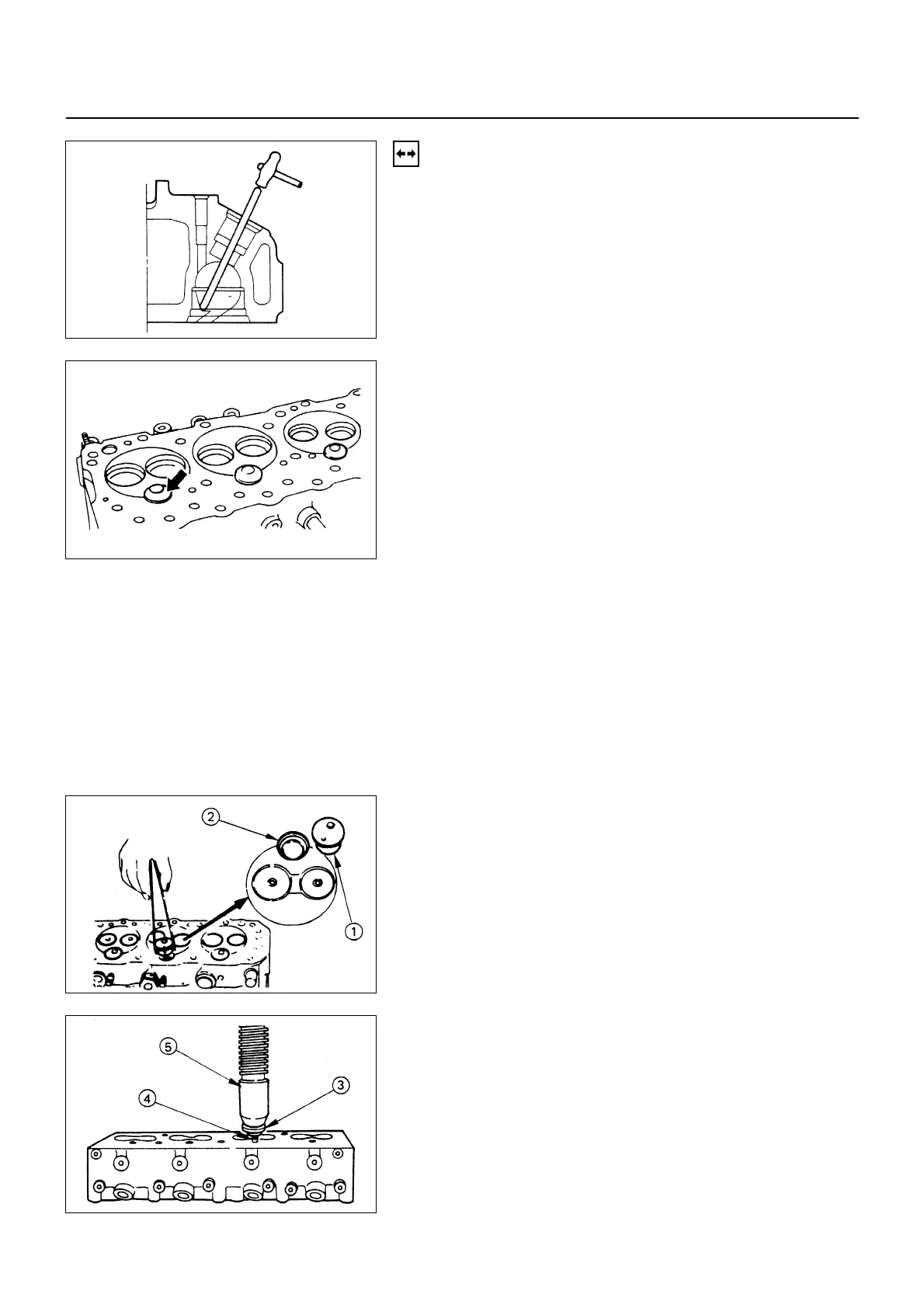

Combustion chamber inspection (4JG2 only)

1. Remove the carbon adhering to the inside of the

combustion chamber. Take care not to damage the

hot plug fitting positions.

2. Inspect the inside of the combustion chamber, the hot

plug, and the hot plug machined faces for cracking

and other damage.

If cracking or damage is present, the cylinder head

must be replaced.

NOTE:

Be absolutely certain that there are no scratches or

protuberance on the combustion chamber surfaces

which will be in contact with the hot plug after it is

installed. There flaws will prevent the hot plug from

seating correctly.

Hot plug inspection

Inspection the hot plugs for excessive wear and other

damage. Replace the hot plugs if either of these

conditions are discovered.

Hot plug installation (4JG2 only)

1. Align the hot plug knock ball

!

with the cylinder head

groove

"

and tap it temporarily into position with a

plastic hammer.

2. Place an appropriate metal plate

#

thick over the hot

plug upper surface

$

3. Use a press

%

to exert a pressure of 44130 - 53937N

(4500 - 5500 kg/9923 - 12128 lbs.) on the metal plate

covering the hot plug upper surface. This will drive the

hot plug into position.

4. Lightly tap the hot plug heads to make sure that they

are firmly seated.

5. Repeat the procedure Steps 1-4 for the remaining hot

plugs.

6A-5-2.tif

6A-5-1.tif

6A-5-3.tif

6A-4-4.tif

Loading...

Loading...