6A – 6 GENERAL ENGINE MECHANICAL

CAUTION:

Do not apply pressure greater than that specified.

Damage to the cylinder head will result.

6. Use a surface grinder to grind off any hot plug surface

protuberances.

The hot plug surfaces must be perfectly flush with the

cylinder head.

7. After grinding, make sure that the hot plug surfaces

are completely free of protuberances.

The hot plug surfaces must also be free of

depressions.

Once again, lightly tap the hot plug heads to make sure

that they are firmly seated.

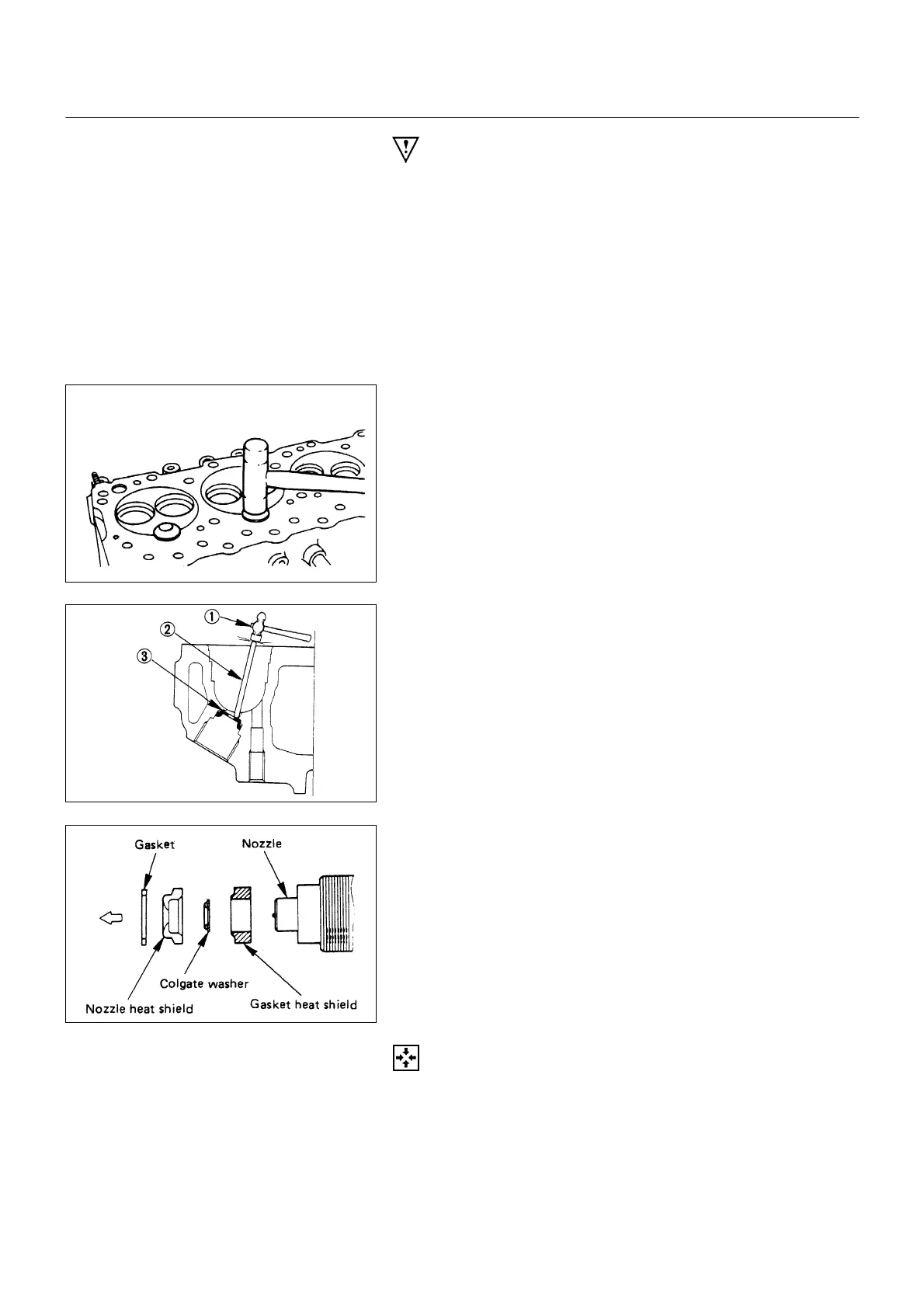

Heat shield removal (4JG2 only)

After removing the hot plugs, use a hammer

!

and a

brass bar

"

to lightly tap the lower side of the heat shield

#

and drive it free.

Heat shield installation (4JG2 only)

Install the heat shield washer and the heat shield to the

cylinder head from the nozzle holder installation hole side.

Lightly tap the flange into place with a brass bar.

The heat shield flange side must be facing up.

NOTE:

Always install a new heat shield. Never reuse the old

heat shield.

REASSEMBLY

6. Cylinder Head

1) Hot plug

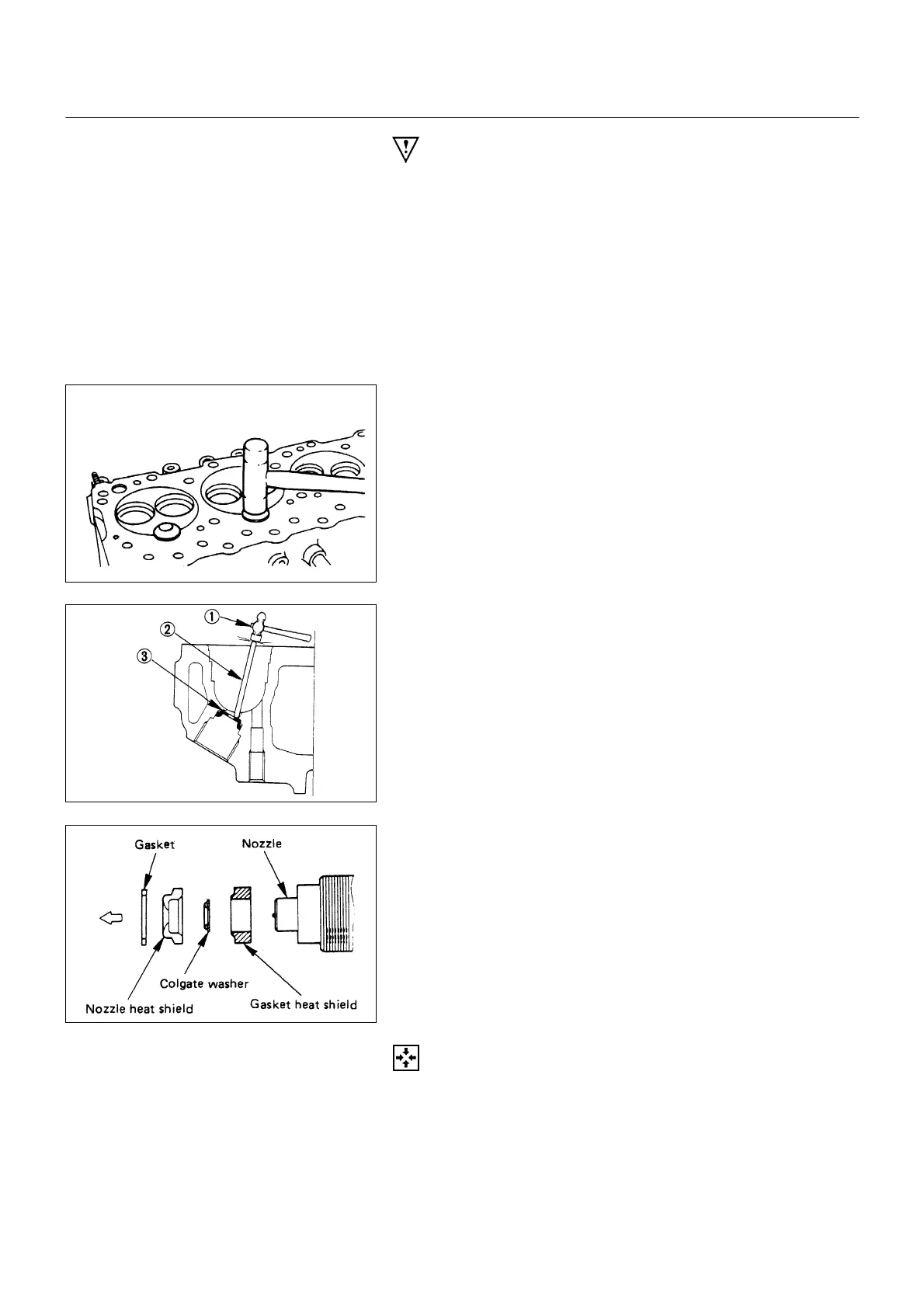

• Set the nock ball in the positioning groove on the

cylinder head side according to the order of the

cylinders, and hit it lightly with a plastic hammer.

6A-6-1.tif

6A-6-2.tif

6A-6-3.tif

Loading...

Loading...