ENGINE FUEL 6C - 19

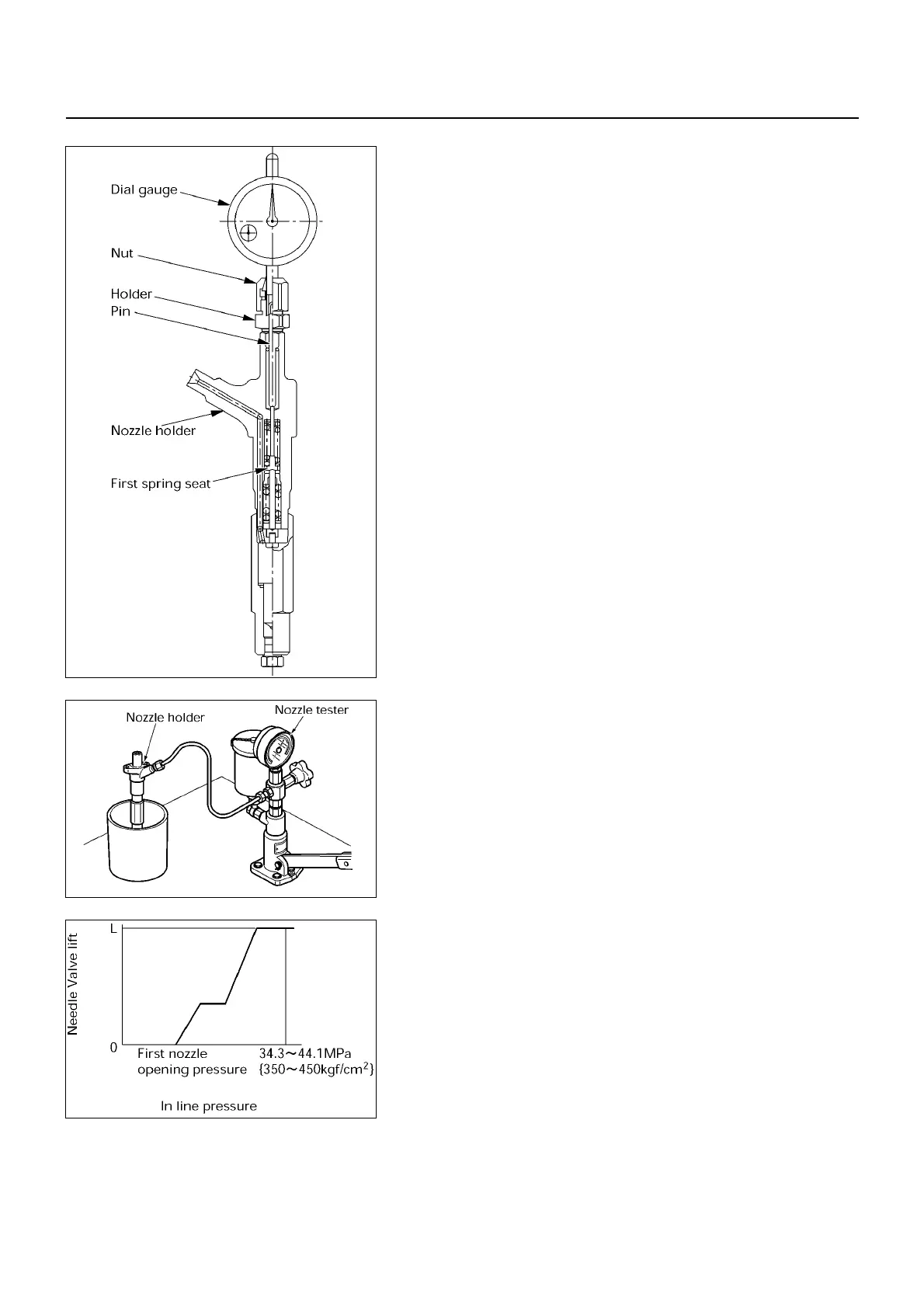

5. Secure the dial gauge to the nozzle holder using the

nut so that the pin contacts the tip of the first spring

seat.

CAUTION:

• Secure the dial gauge so that a stroke of 2 mm can

be measured.

• Do not over-tighten the nut as the dial gauge shaft

may jam. (Confirm from the dial gauge that the

shaft moves smoothly.)

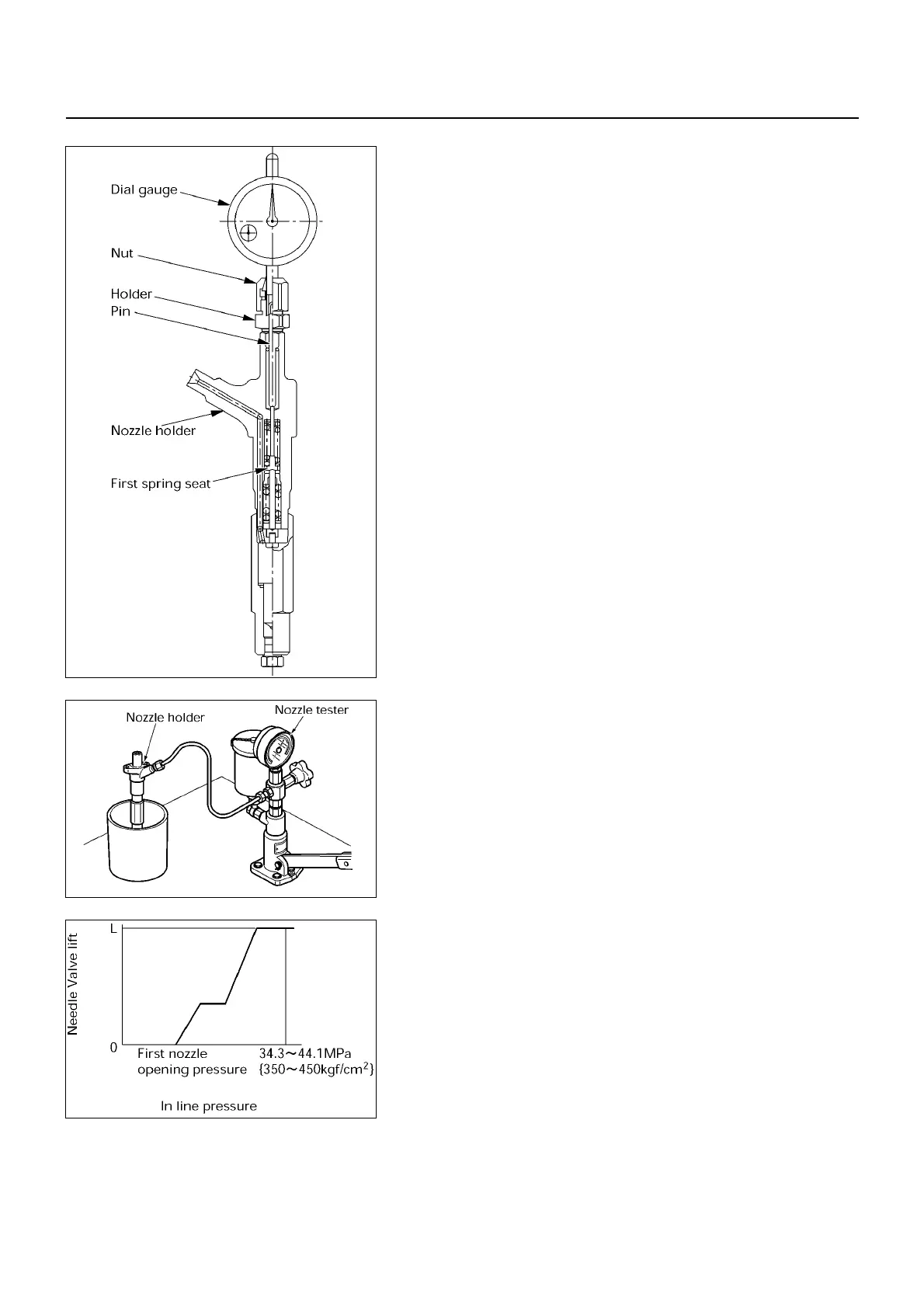

6. Set the nozzle holder to the nozzle tester and put

needle to zero on the dial gauge.

7. Operate the nozzle tester to bleed any air from inside

the retaining nut and to confirm that no fuel leaks.

8. Operate the nozzle tester and increase the in-line

pressure to 34.3 - 44.1 MPa (350 - 450 kg/cm

2

) so that

the nozzle’s needle valve moves through its full lift.

Record full lift ‘L’. (Read dial gauge)

Note:

The above operation is used to determine whether

the nozzle seat is worn and whether the nozzle

assembly is in good condition.

040MV009.tif

040MV030.tif

040MV008.tif

Loading...

Loading...