Page 24

ENGLISH

Jandy

®

, JXi

™

Gas-Fired Pool & Spa Heater

|

Installation & Operation Manual

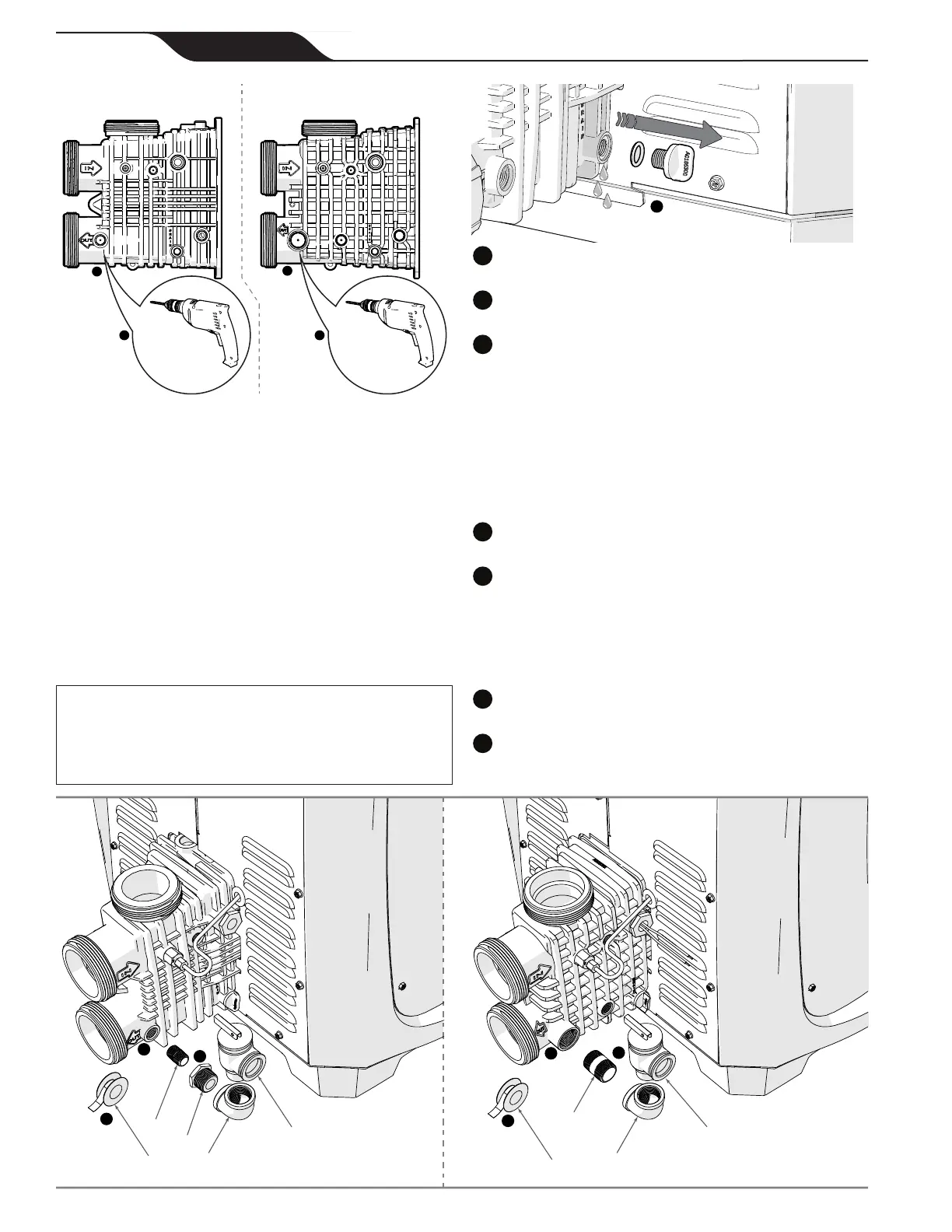

Figure 15. Identifying Header Design

b

b

Drill Using

a 1/4 in Bit

Drill Using

a 3/8 in Bit

Heater Revision “K” and Earlier Heater Revision “L” and Later

Header Type “A” Header Type “B”

cc

TIP: Drilling a 1/8 in diameter hole first will help prevent thread damage.

• Turn off the electrical power to the heater.

• Turn off the main gas supply to the heater.

• If the heater has been operating, ensure you allow

enough time for remaining water in the heat

exchanger to cool down before beginning. It is

recommended that protective gloves be worn during

the entire procedure.

• Make sure the lter pump is off and will remain off

for the duration of the installation procedure.

• If the heater is below the surface level of the water in

the pool or spa, close all shut-off valves between the

heater and the pool.

CAUTION

UsePTFE(Teon)tapeonlyonthethreadsofthepipenippleattach-

ment to the plastic header.

Do not use pipe compound or pipe dope

on threads or any part that comes into contact with the plastic header.

These compounds may damage the header over a period of time.

a

Remove drain plug from header and allow all water to

drain from heat exchanger.

b

Locate the threaded boss on the outlet port of the header,

and nd the dimple at the center.

Use the dimple to center the drill bit.

For header type A: Drill a 1/4 in (6.4 mm) diameter hole

through the boss.

For header type B: Drill a 3/8 in (9.5 mm) diameter hole

through the boss.

Take care not to damage the plastic threads.

TIP: Drilling a 1/8 in (3 mm) diameter hole first will help

prevent thread damage.

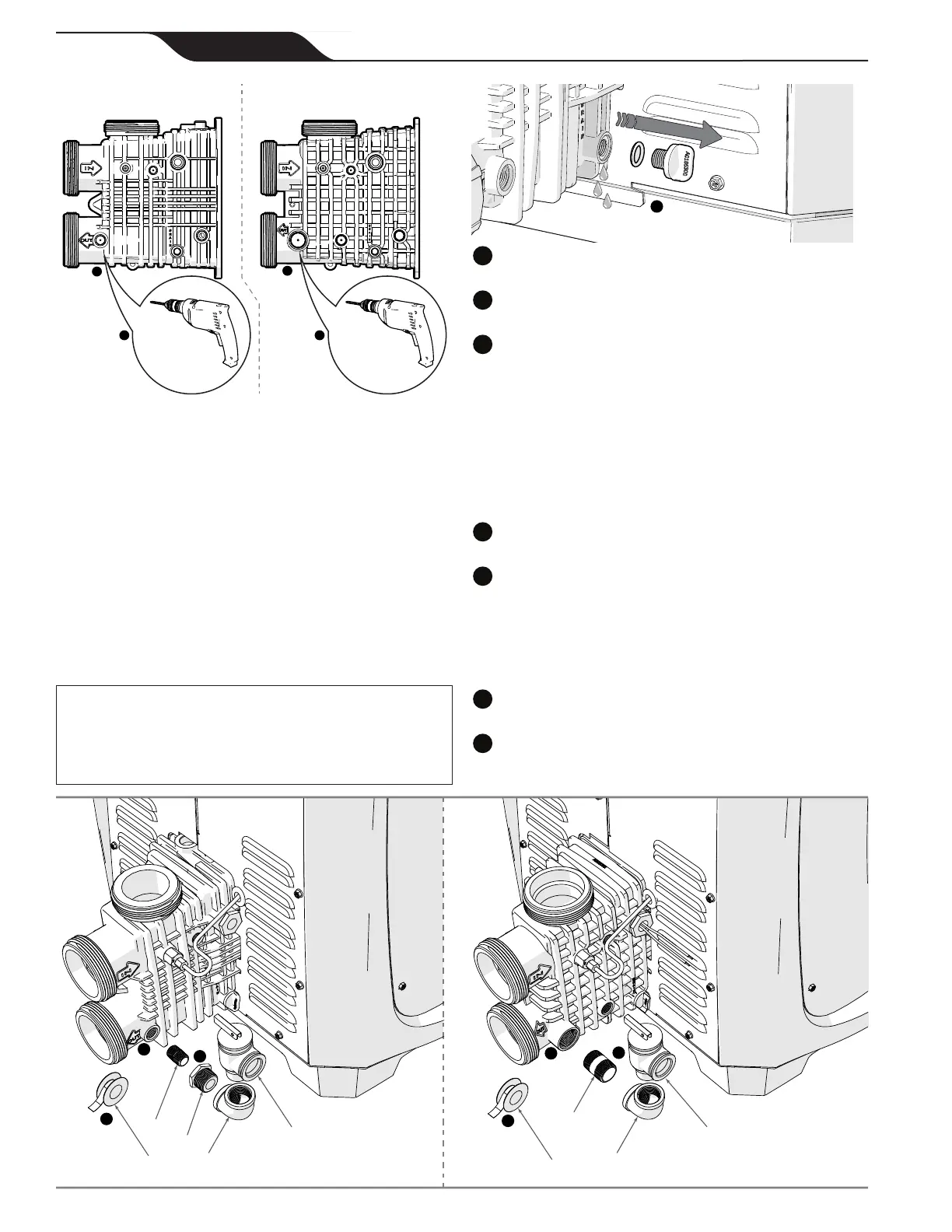

d

Each male connection should be rst wrapped in 5-6 turns

of PTFE (Teon) tape.

For header type A: Assemble the 3/8 in threaded nipple,

reducing bushing, elbow and pressure relief valve. Make sure

to get a sung t. Do not overtighten.

For header type B: Assemble the 3/4 in threaded nipple, elbow

and pressure relief valve. Make sure to get a sung t. Do not

overtighten.

f

Install the pressure relief valve assembly at the heater

header. Make sure to get a sung t. Do not overtighten.

The nal orientation of the pressure relief valve should be

vertically aligned with the discharge opening facing away from

the heater header.

e

e

f

f

d

d

3

1

6

6

2

1

4

55

Header Type “A” Header Type “B”

Loading...

Loading...