42 www.jouleuk.co.uk | www.joule.ie

Primary Pipework

Pressure relief valve

Fill & Flush Valve

Piping insulation

Filter-Ball/ Y-Strainer

This section is applicable to both the Modul-AIR All-E and

Aqua variants.

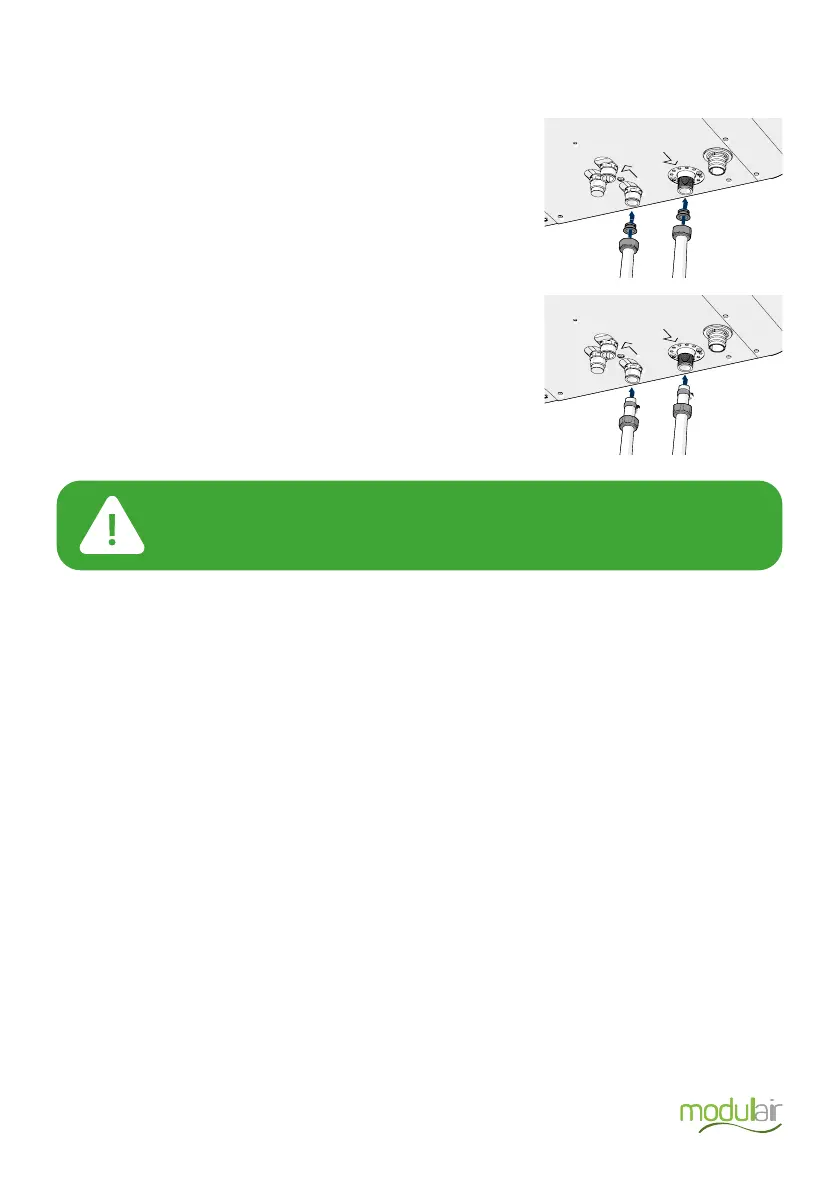

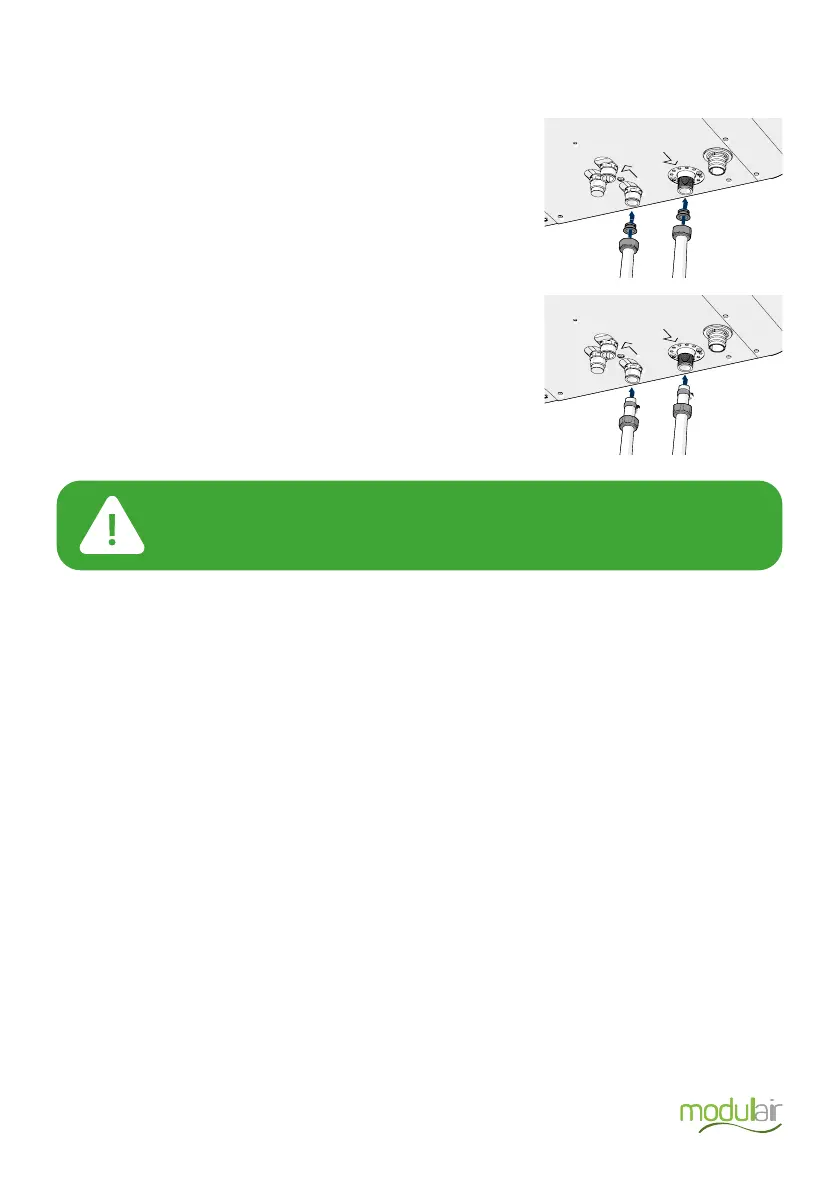

The flow and return connections on the underside of the unit

are 15mm compression.

The Modul-AIR unit can be piped to in both rigid and flexible

pipe. Nuts and olives are supplied with the heat pump.

It is advised to increase the size of the primary pipes to 22mm

copper or 25mm Alu-plex to reduce the resistance.

Isolation valves must be installed directly below the unit to

allow for maintenance and/or repair of the Heat Pump.

Piping the Modul-AIR

The piping system must be flushed out before the Heat Pump is connected

so that any debris will not cause damage to the component parts

The Heat Pump does not have a pressure relief valve incorporated. The installer MUST ensure the system

is protected from over-pressurisation. The valve prevents abnormal water pressure from damaging the

system by opening at a maximum pressure setting of 3.0 bar.

The fill & flush valve must be installed on the primary return aer all system connections have been made.

This ensures that when purging air from the system, the entire system is being purged correctly.

Pipe insulation should comply with BS 5422:2009. Alternatively, insulation of a thickness that provides

reduction of heat loss equivalent to material having a thermal conductivity of 0.035 W/mK at 40°C and

thickness equal to the diameter of the pipe (or 40mm, whichever is smaller) may be used.

Installation of the filter/ strainer is essential to protect the Heat Pump from system debris.

The filter/ strainer must be cleaned aer one day of operation and it must be checked periodically to

maintain the minimum system flow rate.

Loading...

Loading...