49Modul-AIR Exhaust Air Heat Pump Installation Guide

General Pipework

Sizing, positioning and pre-charge pressure of the heating system

expansion vessel

The Exhaust Air Heat Pump does not have an expansion vessel incorporated. The installer must ensure the

system is protected from the effects of expansion by installing a suitably sized expansion vessel.

The vessel prevents water pressure spikes in the system by absorbing the increased pressure as the

temperature increases.

• Only use dry nitrogen or air to set the expansion vessel pressure.

• Inappropriate setting of the expansion vessel pre-charge pressure will lead to malfunction of the

system.

• The pressure should only be set and/or adjusted by a competent installer.

• The adjusting of the pressure should be done before the expansion vessel is installed - i.e. the pipe

connection must be open to atmosphere.

The vessel must be sized in accordance with EN 12828. The following system data will assist in sizing a vessel:

1 Vessel pre-charge pressure *-0.5 bar below working pressure

2 Safety valve set pressure 3 bar, industry standards

3 **The difference in height (H) 0 m, typical install setup

4 Total system volume, in litres Calculated by the installer

5 System maximum temperature 65°C

6 % Antifreeze glycol in the system Zero, as it’s an indoor installation

* A pre-charge pressure of 0.5 bar equates to a static head of 5 metres.

** The difference in height (m) is the difference between the position in which the safety valve is installed

and the position of the vessel.

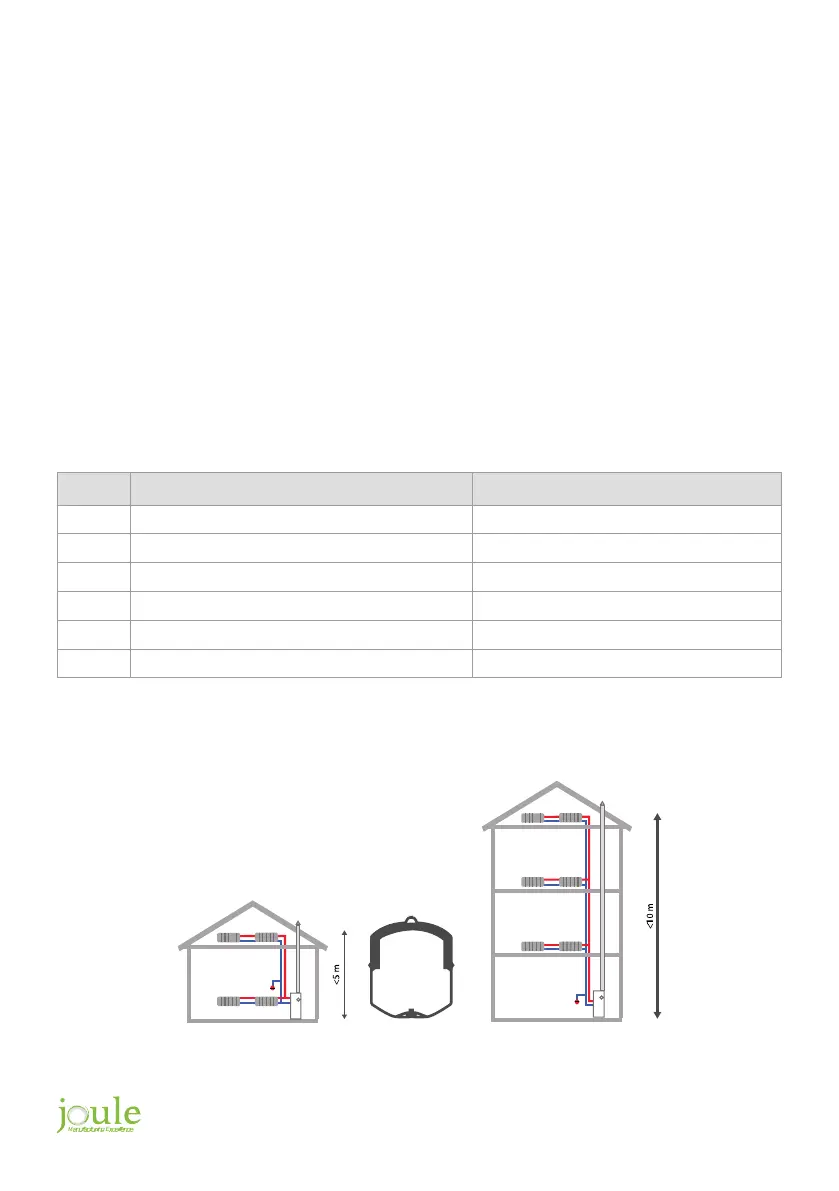

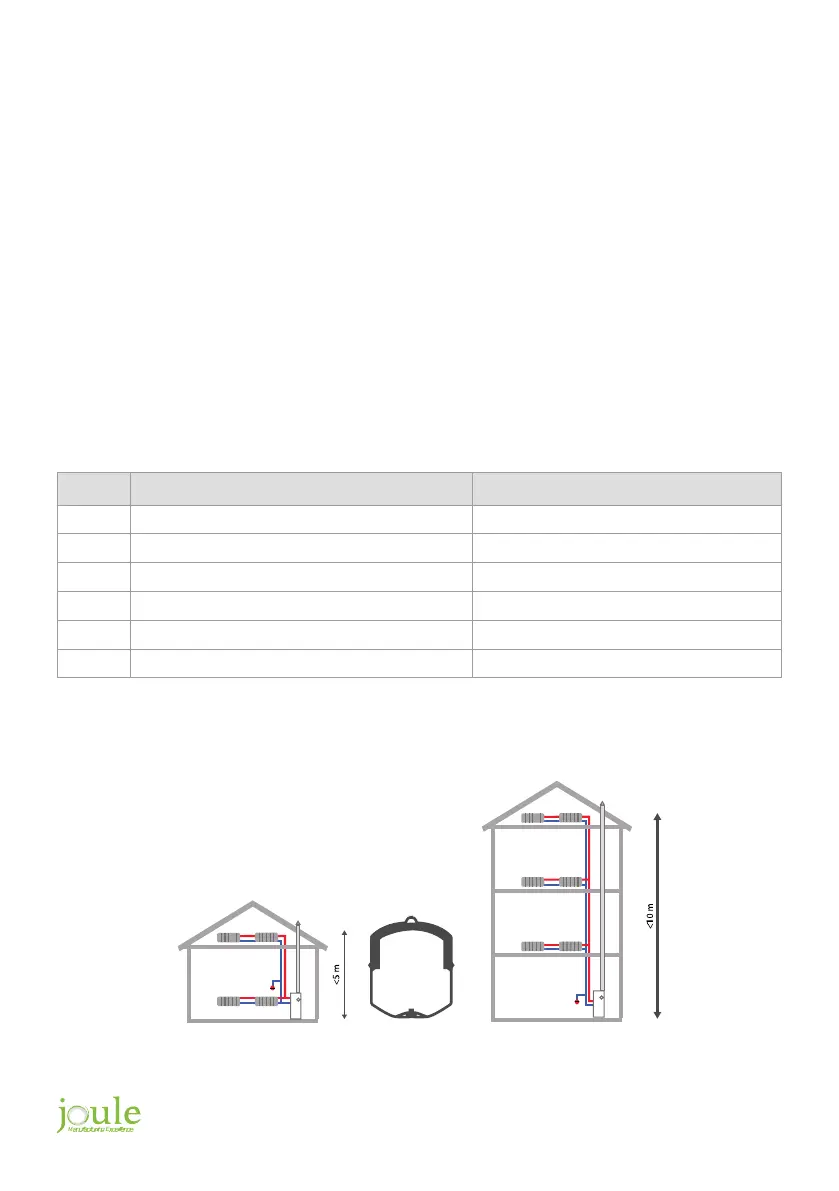

Pre-Charge Pressure 0.5 bar Pre-Charge Pressure 1.0 bar

Loading...

Loading...