Industrial Sewing Machine SADE

111

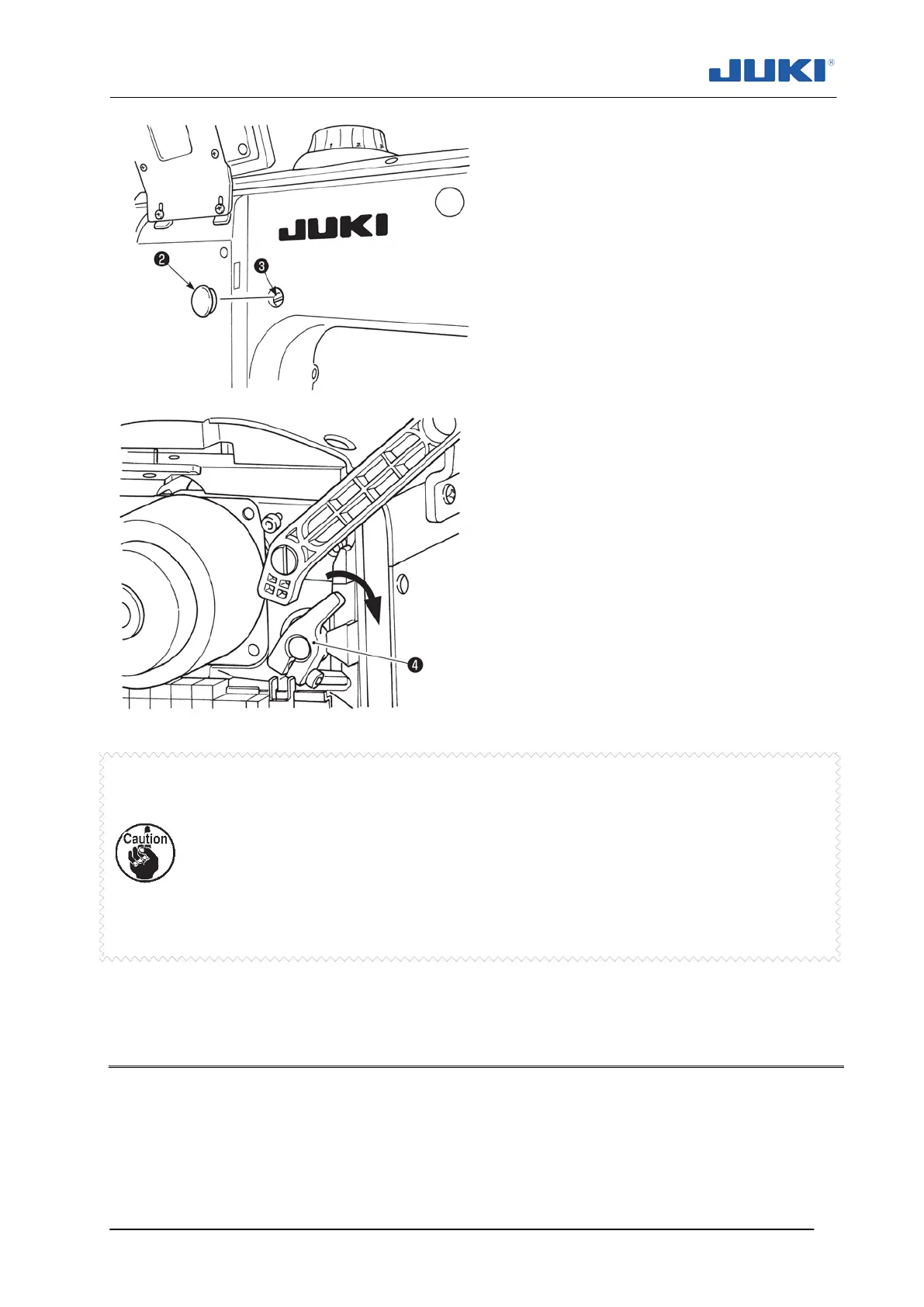

4) Remove rubber cap ❷ from the rear

face of the machine arm. Loosen set-

screw ❸.

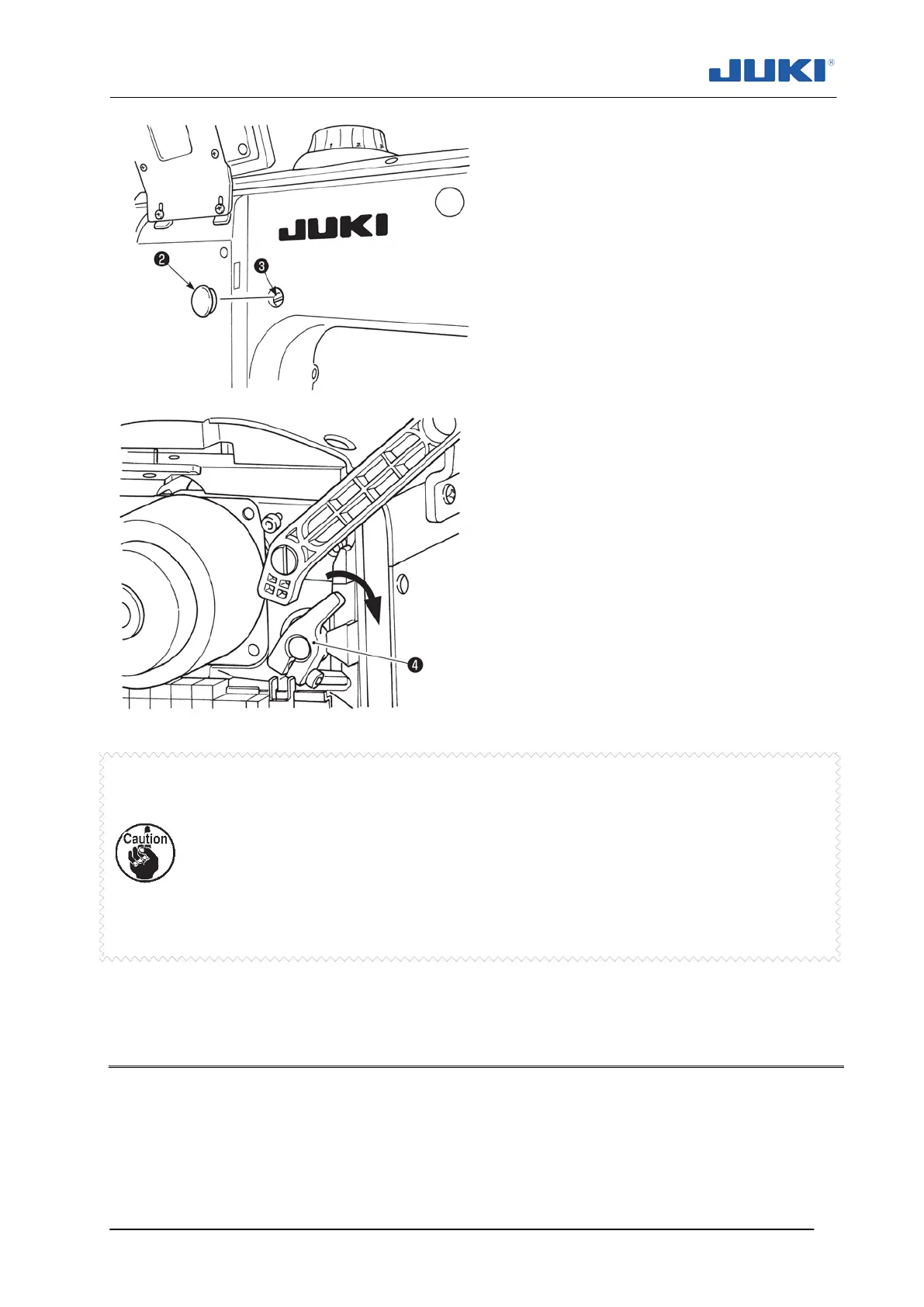

5) Turn presser bar lifting arm ❹ in the di-

rection of the arrow until it will go no fur-

ther. Then, tighten setscrew ❸.

For the standard gauge type machine, the top end of the walking foot inter-

feres with the needle bar frame when the auto-lifter is

amount of the alternating vertical movement of the walking

presser foot is set at 2 mm or smaller and in the case it is set at 7 mm or

more and the reverse-rotation needle-up is carried out.

To use the machine with the amount of the

alternating vertical movement of

the walking foot and the presser foot set at 2 mm or less,

amount of the presser foot by means of the auto-lifter at 17 mm or less.

7.8 Normal-/reverse-feed stitch needle entry points alignment at the

time of automatic reverse feed stitching

When the sewing speed or stitch pitch is changed, the normal- and reverse-feed stitch

needle entry points may not be aligned at the time of automatic reverse feed stitching.

In such a case, correct the alignment of needle entry points by changing the ON/OFF

timing of the automatic reverse feed cylinder.

Loading...

Loading...