TECHNICAL DESCRIPTION MULTICAL

®

401

5512-091 GB/02.2008/Rev. J1

64

14.3.5 Heat coefficient in flow and return

When the calibration values for the temperature simulators are entered into the program, it automatically

calculates the true k-factor, according to the formula in EN 1434.

14.3.6

Test points

The test points 1st, 2nd, and 3rd are determined by the value of the temperature simulation resistances, which

are mounted in the test equipment. The rated temperature points are indicated in above section.

14.3.7

Measured resistance

In order to update the temperature simulators’ calibration, the temperature resistances’ latest measured

resistance values are entered. A calibration sheet with declaration of measured resistance values for all

simulators is supplied by Kamstrup A/S together with the verification equipment. The temperature simulators

must be calibrated at Kamstrup A/S once a year.

14.3.8

Enter number of integrations

In this field, enter the number of integrations required at each test point. Minimum required No. of integrations is

5, 2, and 1 concerning 1st, 2nd, and 3rd test. A higher number will reduce the reading uncertainty, but will

prolong the verification time.

14.3.9

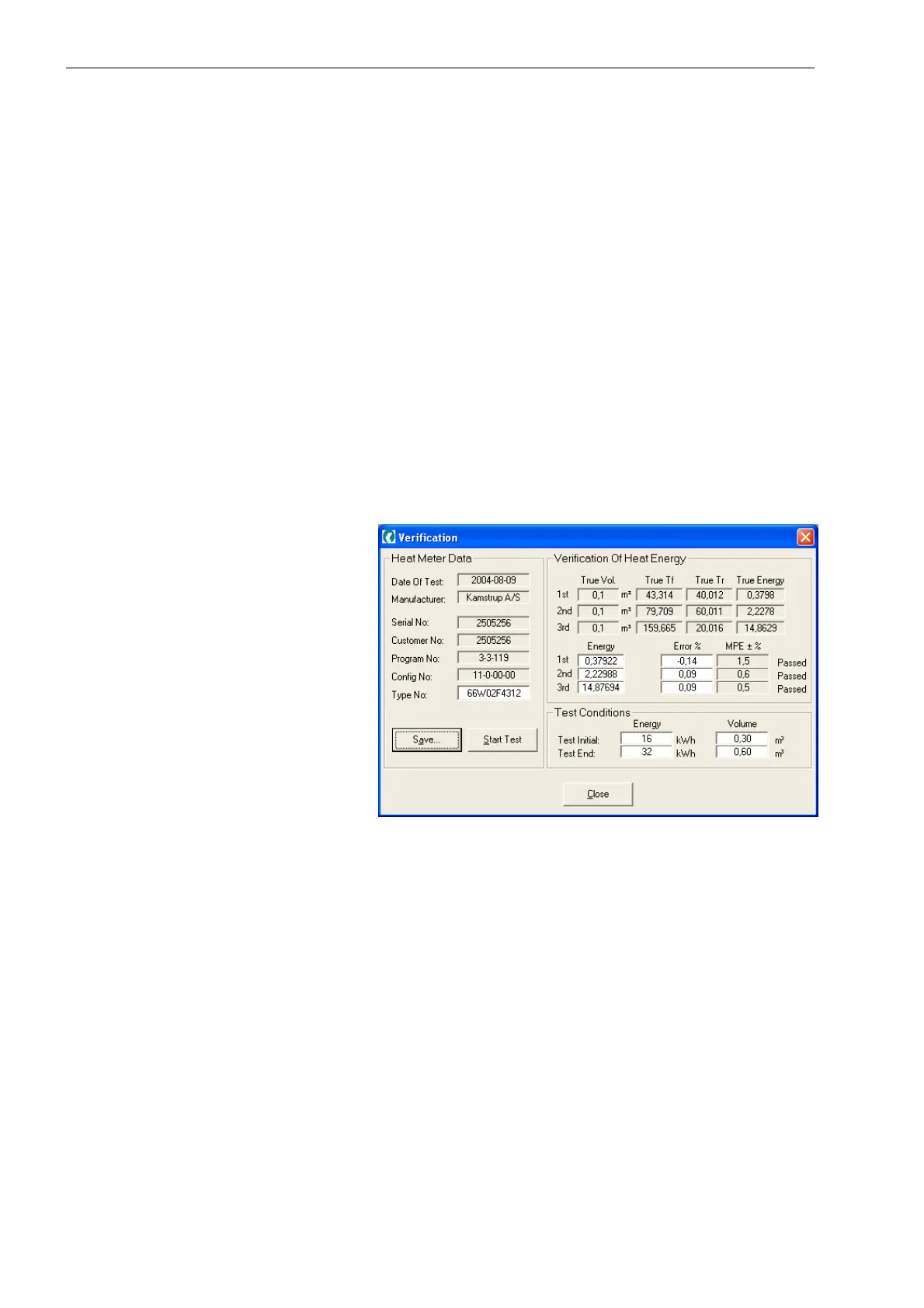

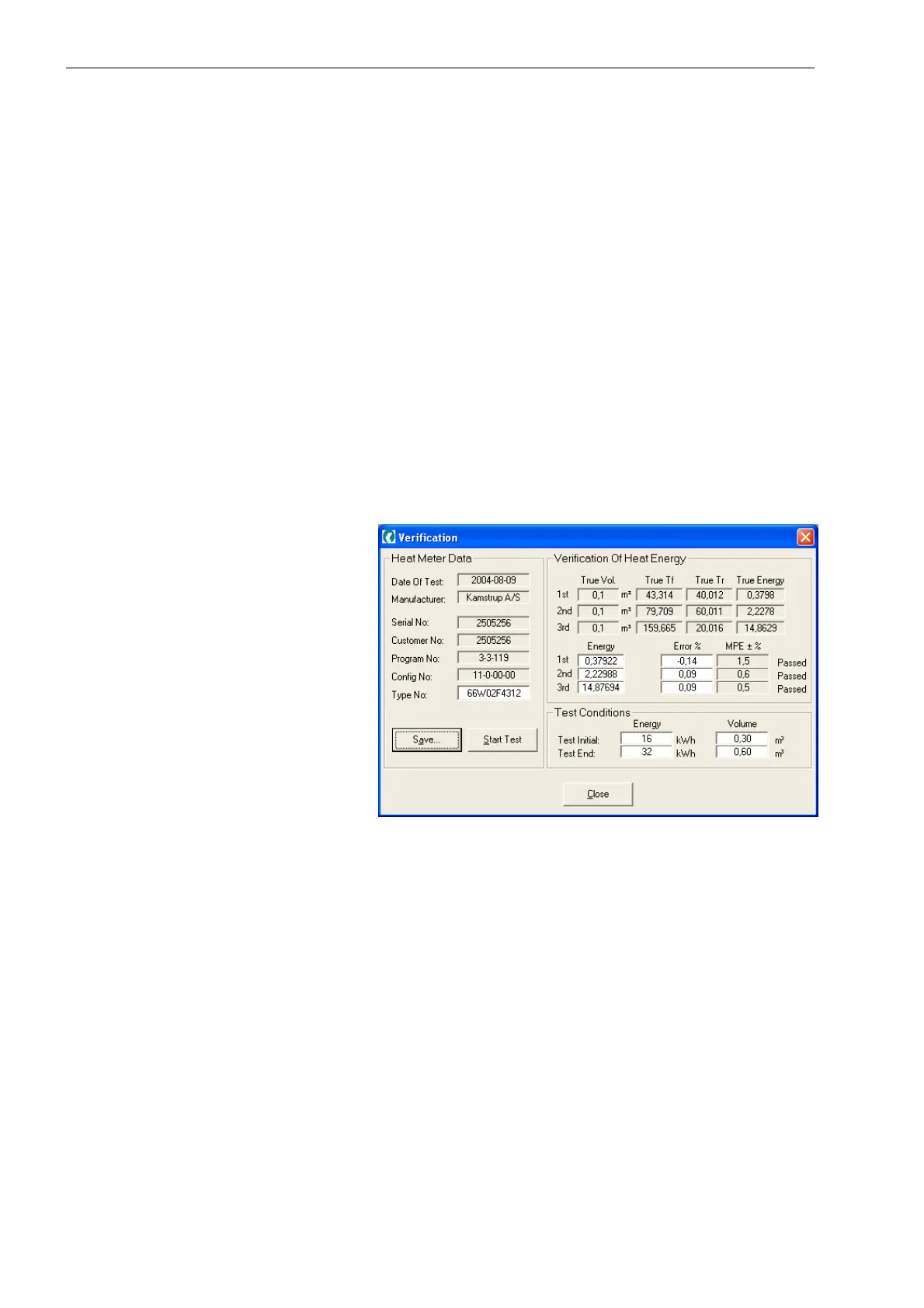

Verification

All necessary information can be transmitted

directly from the calculator via serial data

transmission, which simplifies the

verification. Before test or verification can be

started, a control must be made to confirm

that all verification data are correct.

The procedure is started by clicking on

“Start test”.

The test takes between one and five minutes

depending on the number of integrations.

When the test is completed, the results are

shown on the monitor. If the results can be

approved, click on “Save”, and all

verification data will be saved in the

database under the calculator serial number.

It is possible to save data on both

verification and control. Up to 99 certificates

can be saved at each serial number (per meter).

Figure 58

NB: Type number must be typed in before clicking on “Save”.

If a printed certificate with the test results is desired, select “Print certificate” in the “File” menu, and the required

S/N is selected.

14.3.10

Maintenance

Verification equipment type 66-99-385 is designed to work a number of years with a minimum of maintenance.

The following must, however, be executed frequently in order to ensure optimal operation:

Recalibration

On delivery, a calibration certificate is enclosed issued by Kamstrup A/S. The applied calibrated resistance values

must be entered under “Verification data”. The equipment must be recalibrated once a year.

Loading...

Loading...