b0.13 Oscillation inhibition

coefficient

Adjust this parameter can prevent motor oscillation

when drive using V/F control.

6.11 Group b1

b1.01 V/F frequency value

F3 of motor 1

b1.02 V/F voltage value V3

of motor 1

b1.03 V/F frequency value

F2 of motor 1

b1.04 V/F voltage value V2

of motor 1

b1.05 V/F frequency value

F1 of motor 1

b1.06 V/F voltage value V1

of motor 1

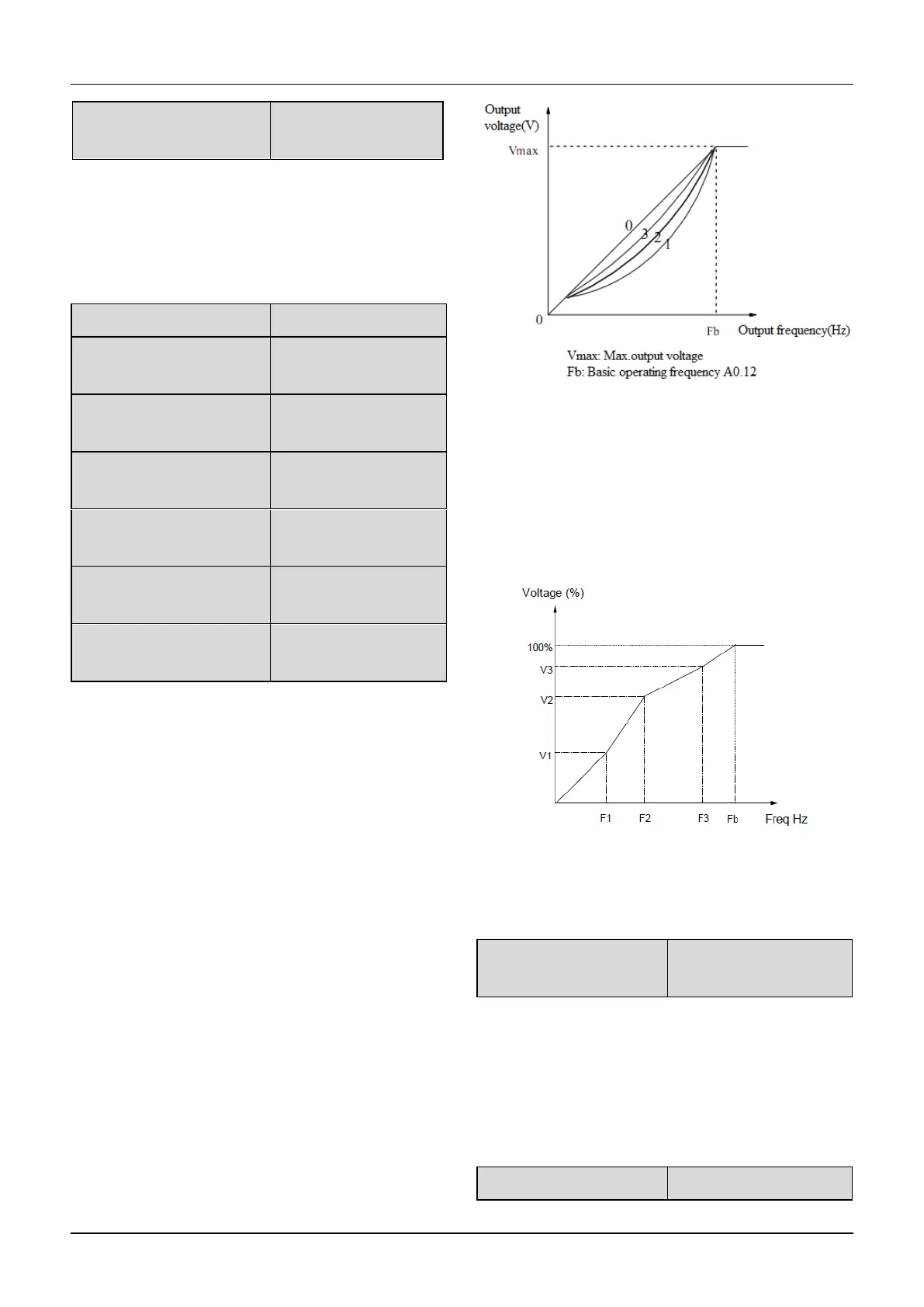

This group of parameters define the V/F setting modes

of SV100 so as to satisfy the requirements of different

loads. 3 preset curves and one user-defined curve can

be selected according to the setting of b1.00.

If b1.00 is set to 1, a 2-order curve is selected, as shown

in Fig. 6-35 as curve 1;

If b1.00 is set to 2, a 1.7-order curve is selected, as

shown in Fig. 6-35 as curve 2;

If b1.00 is set to 3, a 1.2-order curve is selected, as

shown in Fig. 6-35 as curve 3;

The above curves are suitable for the variable-torque

loads such as fan & pumps. You can select the curves

according to the actual load so as to achieve best

energy-saving effects.

Fig.6-35 Torque-reducing curve

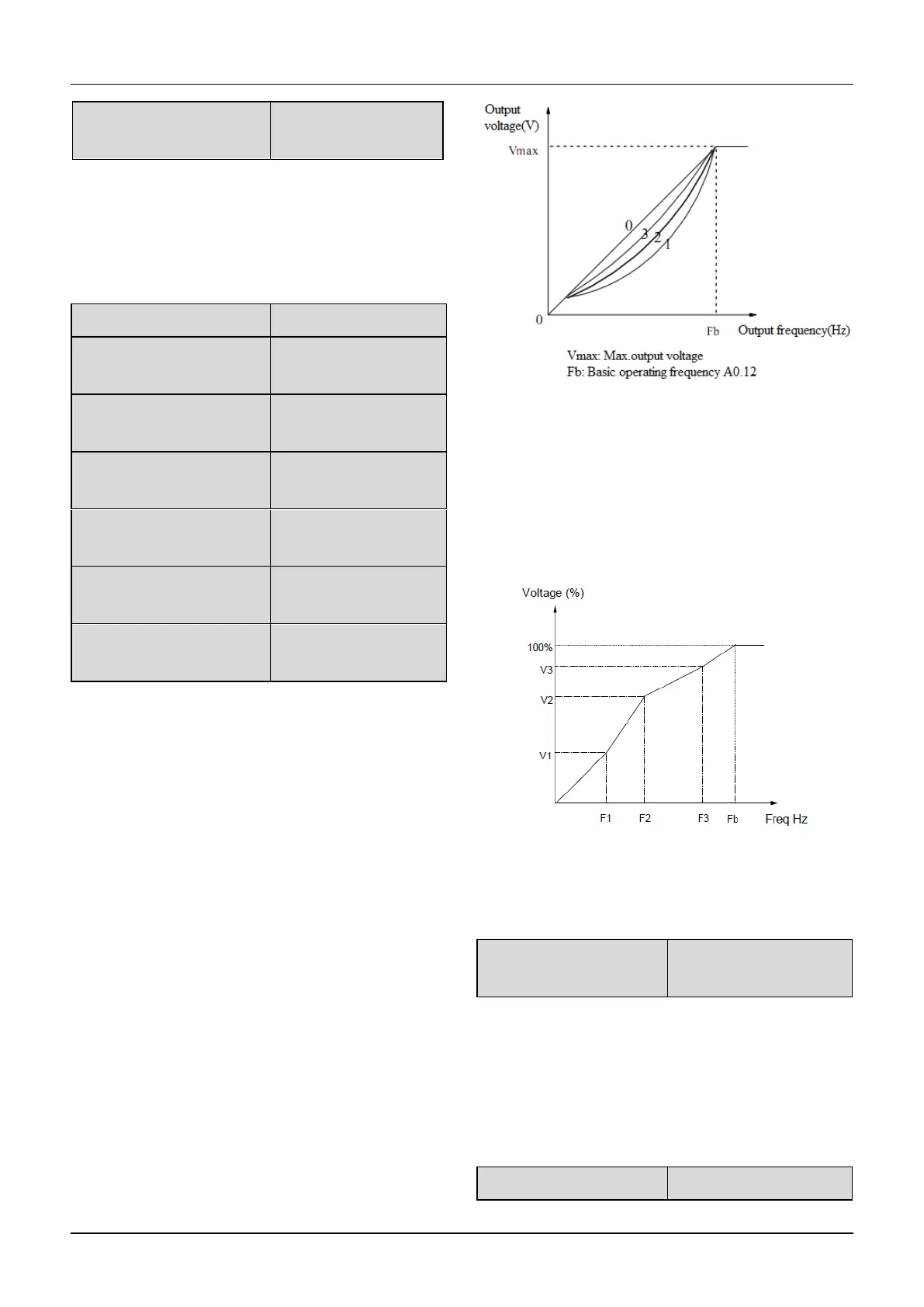

If b1.00 is set to 0, you can define V/F curve via

b1.01~b1.06, as shown in Fig. 6-36. The V/F curve can

be defined by connecting 3 points of (V1,F1), (V2,F2)

and (V3, F3), to adapt to special load characteristics.

Default V/F curve set by factory is a direct line as show

in Fig. 6-35 as curve 0.

Fig.6-36V/F curve defined by user

b1.07 Cut-off point used

for manual torque boost

b1.07 defines the ratio of the cut-off frequency used for

manual torque boost to the basic operating frequency

(defined by A0.12), as shown in Fig. 6-36 as Fz.This

cut-off frequency adapts to any V/F curve defined by

b1.00.

V1~V3: Voltage of sections 1~3

F1~F3: Freq of sections 1~3

Fb:Basic operating frequency of A0.12

Loading...

Loading...