feedback value (C1.05~C1.08) should be defined for

analog close-loop control;

3)Determine the close-loop regulation characteristic, if

the relationship between motor speed and the reference

is opposite,then set the close-loop regulation

characteristic as negative characteristic(C1.15=1).

4)Set up the integral regulation function and close-loop

frequency presetting function (C1.16~C1.18);

5)Adjust the close-loop filtering time, sampling cycle,

error limit and gain(C1.09~C1.14).

C1.00 Close-loop control function

0:Disable.

1:Enable.

C1.01 Reference channel selection

0: digital input

Take the value of C1.03.

1: AI1 analog input.

2: AI2 analog input

C1.02 Feedback channel selection

0:AI1 analog input

1:AI2 analog input

2:AI1+ AI2

3:AI1-AI2

4:Min{ AI1,AI2}

5:Max{ AI1,AI2}

Settings of AI are the same as above.

C1.03 Digital setting of

reference

This function can realize digital setting of reference via

panel or serial port.

C1.04 Close-loop speed

reference

C1.06 Feedback value

corresponding to the Min

reference

C1.08 Feedback value

corresponding to the Max

reference

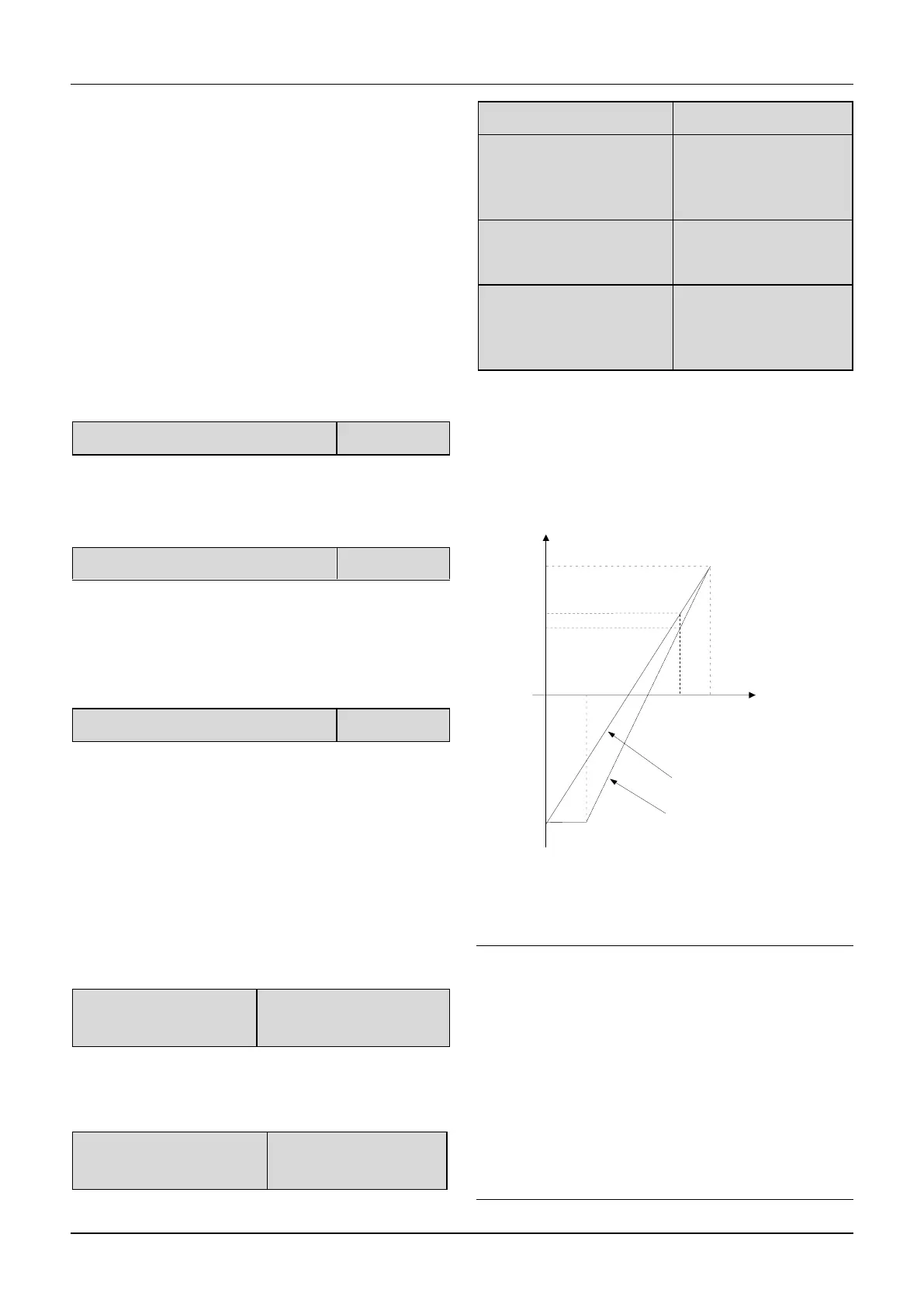

The regulation relationship between C1.05,C1.07(in

Fig.6-39) and reference is shown in Fig.6-41.When the

analog input 6V,if C1.05=0% and C1.07=100%,then

adjusted value is 60%.If C1.05=25% and C1.07=

100%,then the adjusted value is 46.6%.

Fig.6-42 Regulation curve of reference

Note:

1.Fig.6-42,0%~100% in X axis is corresponding to

analog input - 10V ~ 10V,10V of analog input is

corresponding to 100%,and-10V is corresponding to

0%,6V is corresponding to 80%.

2. If the analog type is current input,because the

currentinput range is 4~20mA,then the range of X axis

is 50%~100%.

Loading...

Loading...