Section 2

Installation

20425561

5-2005/Rev 0

2-10

Hand Coning

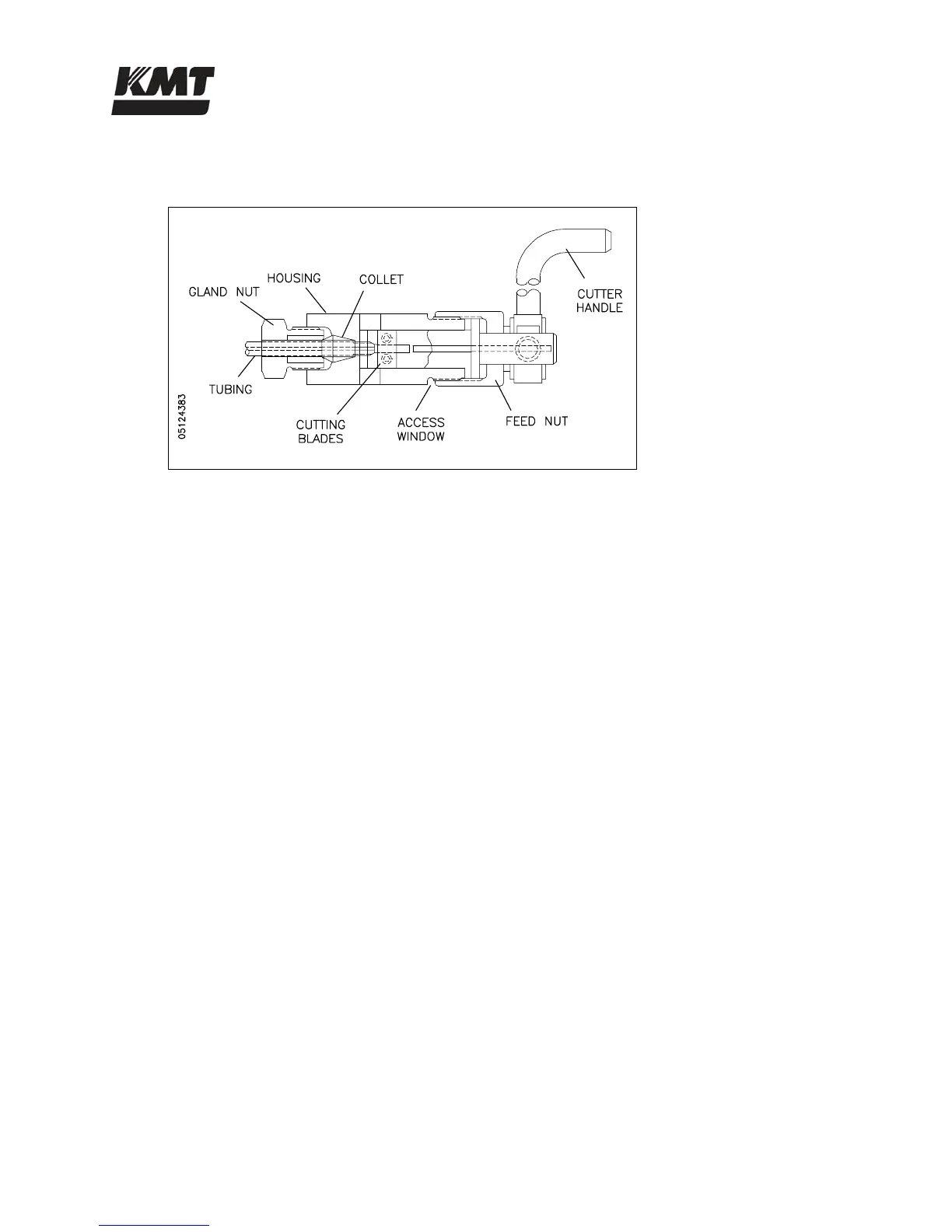

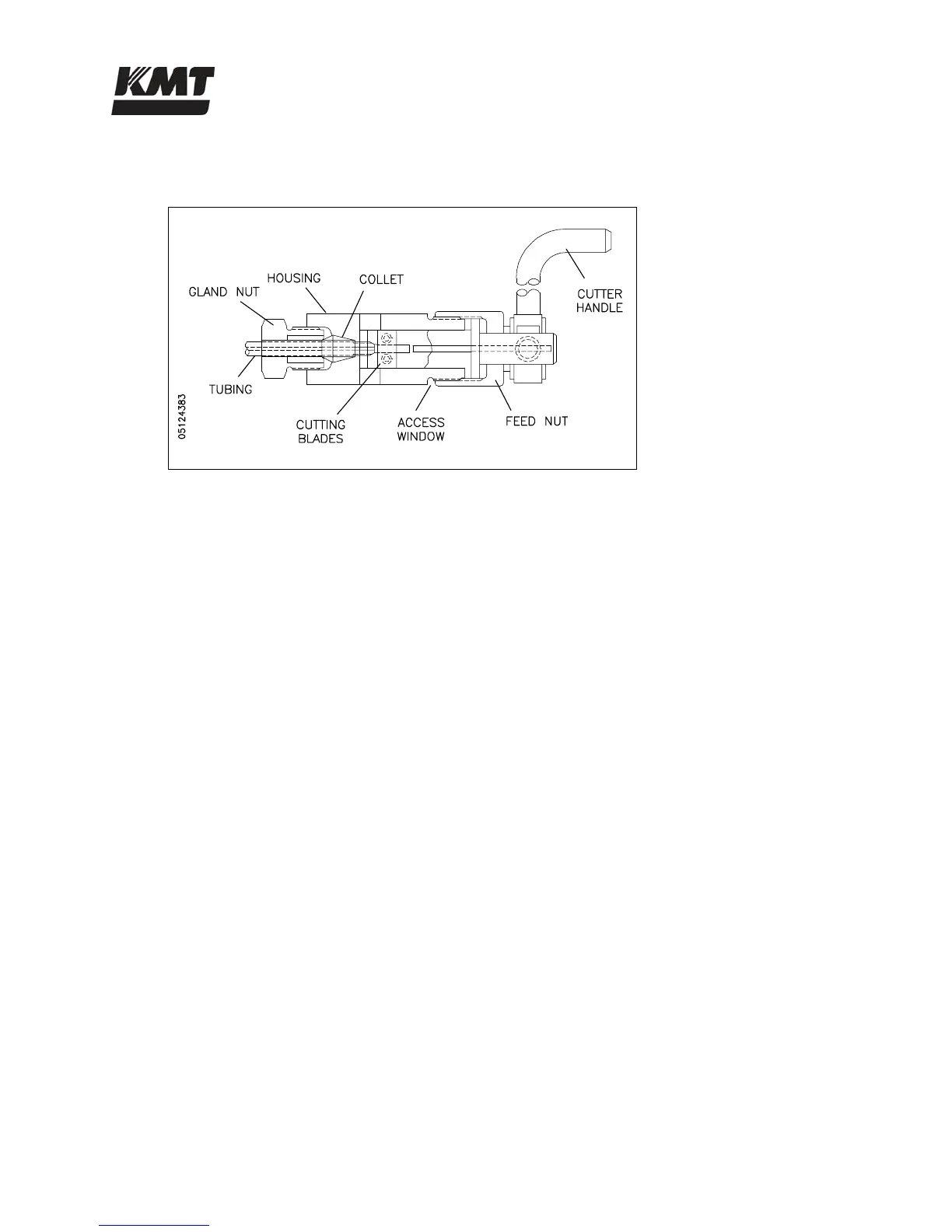

Figure 2-7: Hand Coning Tool

1. Place the body of the coning tool in a vise allowing adequate clearance for the rotation of

the cutter handle. Position the tool so the cutter handle is elevated slightly so the lubricant

will flow to the cutting blades.

2. Turn the feed nut counter-clockwise to retract the cutting blades past the access window.

3. Loosen the gland nut and insert the tubing through the collet. The end of the tubing

should just make contact with the cutting blades. Loosely tighten the gland nut to slightly

grip the tubing.

4. Turn the feed nut counter-clockwise 1/4 turn to retract the cutting blades away from the

tubing, and tighten the gland nut with a wrench.

5. Apply a liberal amount of cutting oil to the exposed end of the tubing, the cutting blades

and through the lubrication channel at the cutter handle.

Apply cutting oil frequently and liberally throughout the cutting operation. A medium

weight cutting oil with high sulfur content is recommended.

6. Turn the feed nut clockwise until the cutting blades contact the end of the tubing.

7. In a smooth, continuous motion, turn the cutter handle in a clockwise direction.

Simultaneously turn the feed nut in a clockwise direction to establish a constant feed. Do

not remove too much material at once; the cutting blades should make light, uninterrupted

cuts.

Loading...

Loading...