Section 8

High Pressure Water System

20425618

5-2005/Rev 0

8-20

stroke. Polish the sealing head until it is flat and smooth. Be careful not to cause

additional damage by tilting or tipping the part while polishing.

3. When the sealing head is flat and smooth, perform a final polish with 600-grit wet/dry

sandpaper.

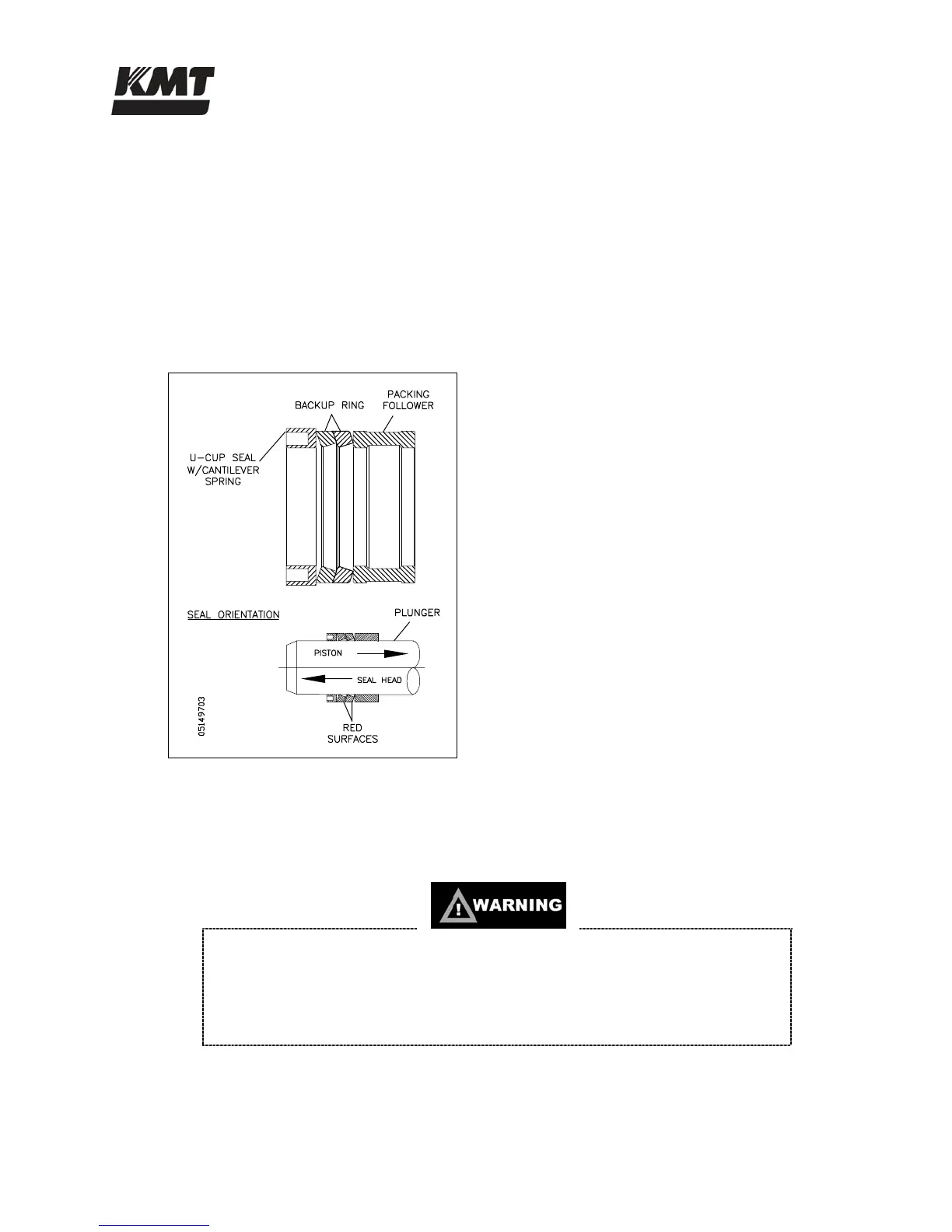

8.10 High Pressure Seal Assembly

The following procedure should be used to replace the high pressure seal assembly.

Figure 8-12: High Pressure Seal Assembly

Prior to removing electrical power or any high or low pressure piping, start the machine and

extend the plunger on the end to be serviced to allow full exposure when the unit is disassembled.

1. Turn the machine off and observe the appropriate Lockout/Tagout procedures.

Severe injury can result if the machine is not properly locked out. Observe

electrical Lockout/Tagout procedures before proceeding.

Ensure all pressure is relieved or blocked from the hydraulic and high pressure

circuits before proceeding.

2. Disconnect the high and low pressure water piping, following the procedure, High and

Low Pressure Water Piping.

Loading...

Loading...