Section 8

High Pressure Water System

20425618

5-2005/Rev 0

8-16

9. Connect the high and low pressure water piping and turn the low pressure water supply

on.

10. Start the machine in low pressure mode to flush air from the high pressure components

and to check for obvious leaks. After 5-10 strokes, switch to high pressure operation and

check for leaks.

If leaks are detected, turn the machine off and remedy the problem. When the problem

has been remedied, repeat the startup procedure, moving from low to high pressure soon

after the intensifier starts pumping water. There is no further need to flush air from the

system.

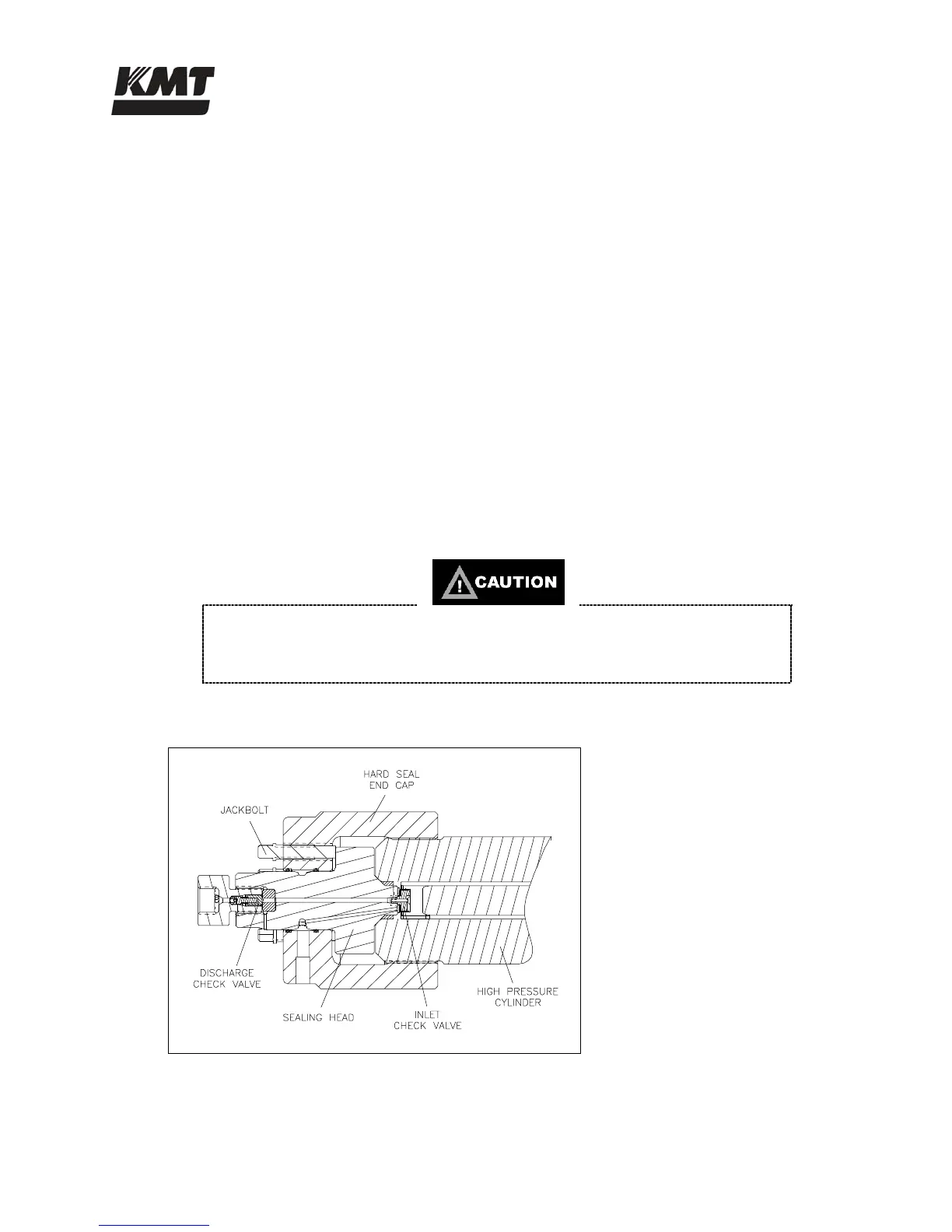

8.9 Sealing Head

The sealing head is sealed to the outboard end of the high pressure cylinder by a 45-degree metal-

to-metal compression seal. The pre-loading jackbolts in the hard seal end cap hold the sealing

head against the end of the cylinder.

The inlet and discharge check valves in the sealing head ensure the low pressure and high

pressure water only travels in the appropriate direction.

If normal operating pressure will not exceed 50,000 psi (3,447 bar), the alternate

inlet poppet valve must be installed prior to operation. Follow the procedure Low

Pressure Inlet Check Valve. Refer to Table 11-4, Section 11, Parts List.

Figure 8-9: Sealing Head

Loading...

Loading...