Section 2

Installation

20425561

5-2005/Rev 0

2-14

2. Slip the gland nut onto the tubing.

3. Apply Pure Goop to the threads on the tubing. Screw the collar onto the threaded end of

the tubing leaving 1-1/2 to 2-1/2 threads exposed on the tubing between the collar and the

coned tubing.

4. Apply Pure Goop to the male threads on the gland nut and insert the tubing into the

connection. Engage the gland nut and tighten finger tight.

5. Tighten the gland nut to the torque specifications in Table 2-8.

Proper piping supports and guides must be provided. End connections will not

support the tubing load alone.

Table 2-8

Torque Specifications

High Pressure Connections

1/4” Tubing 25 ft-lb (34 Nm)

3/8” Tubing 50 ft-lb (68 Nm)

9/16” Tubing 110 ft-lb (149 Nm)

Anti-Vibration Connections

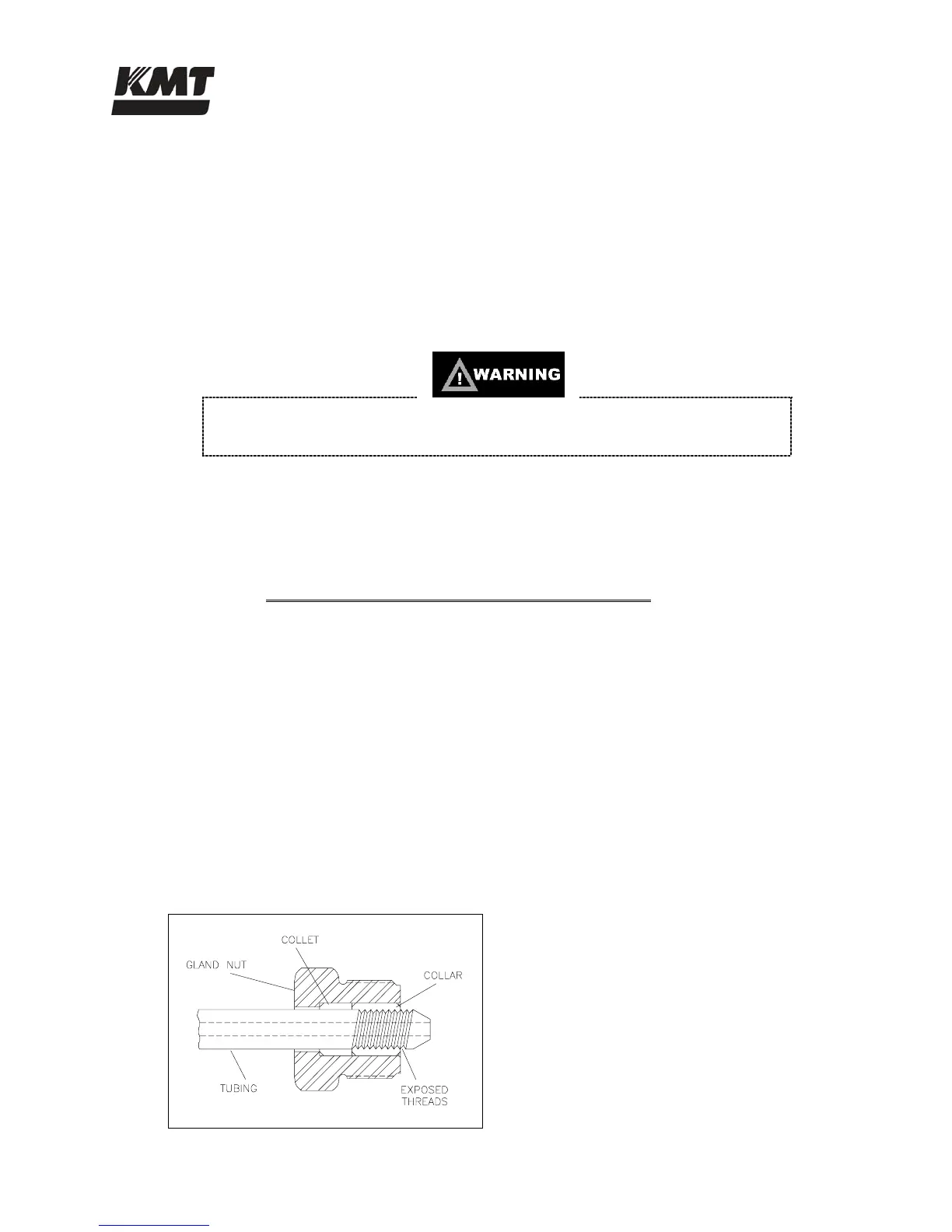

The bending stresses resulting from excessive vibration or shock on the threaded area of the

tubing can cause premature failure at the back of the thread. When tubing will be subjected to

vibration, rotation and movement, anti-vibration connections must be used. The anti-vibration

collet gland transfers the stress to the unthreaded section of the tubing, and the gripping action of

the collet strengthens the entire assembly.

Figure 2-9: Anti-Vibration Connections

Loading...

Loading...