Section 6

Hydraulic System

20425603

5-2005/Rev 0

6-16

REDUNDANT MODELS

Install the hydraulic manifold ensuring that the o-ring is properly positioned.

Torque the mounting bolts to 35 ft-lbs (47 Nm).

Reconnect the sensors and connections to the manifold.

17. Reconnect all hydraulic hoses and connections.

18. Refill the hydraulic reservoir following the procedure, Hydraulic Oil Replacement,

detailed in the Flexible Coupling Replacement procedure.

19. Start the motor and apply full high pressure water pressure. Inspect for hydraulic leaks

and note any unusual sounds from the motor or pump assembly.

Electric Motor Replacement

1. Complete Steps 1-7 in the previous procedure.

2. Remove all electrical leads from the motor.

3. Remove the bolts attaching the vibration isolation mounts to the frame base plate and

remove the old motor from the frame.

4. Stand the new motor on the fan cowl with the shaft pointing upward.

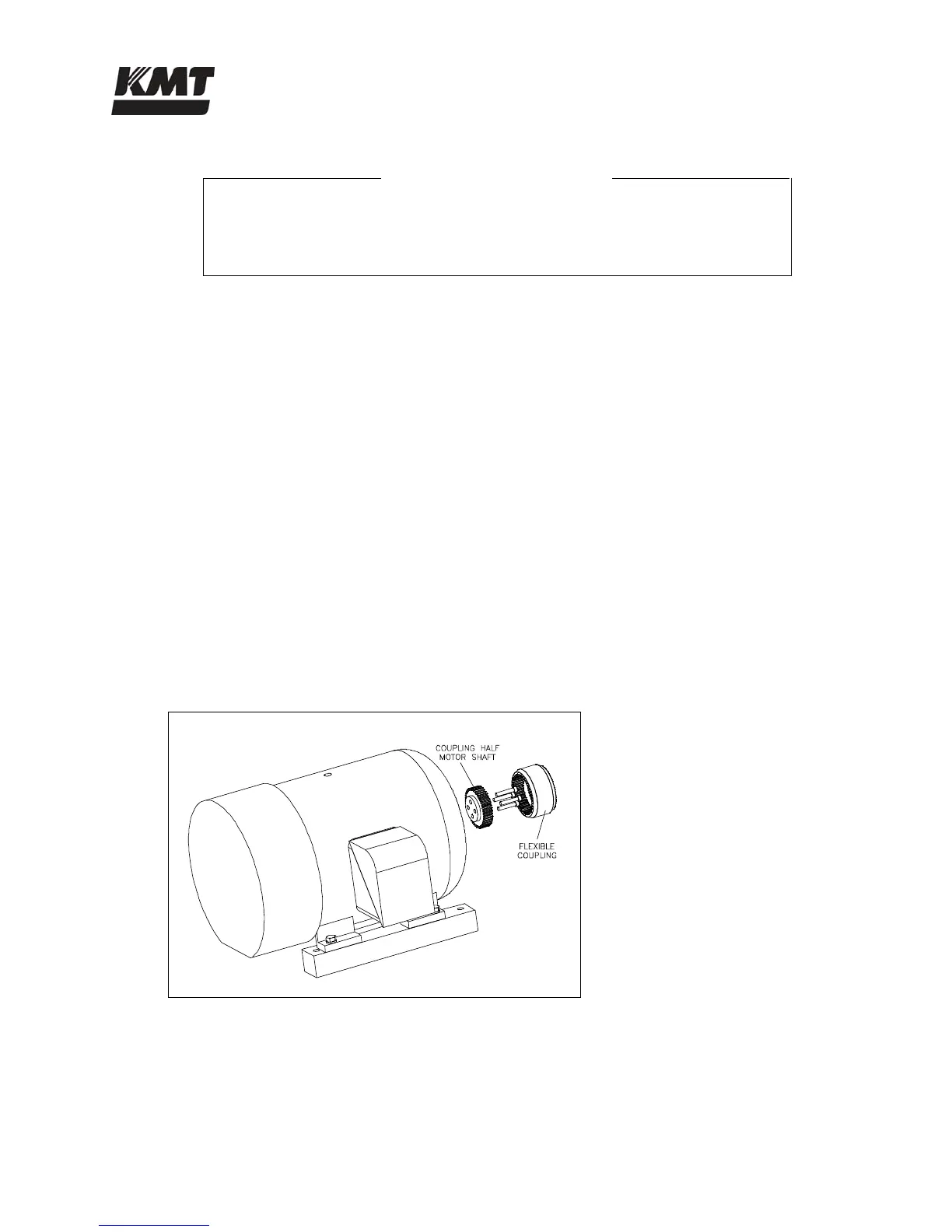

Figure 6-10: Motor Coupling Half

5. Apply Loctite 222 to the bolts and attach a new motor coupling half to the motor shaft.

Torque to 36 ft-lbs (49 Nm).

Loading...

Loading...