Section 8

High Pressure Water System

20425618

5-2005/Rev 0

8-23

3. Remove the proximity switch on the end of the hydraulic cylinder to be serviced.

4. Remove the high pressure cylinder assembly, following the procedure, High Pressure

Cylinder Assembly Removal.

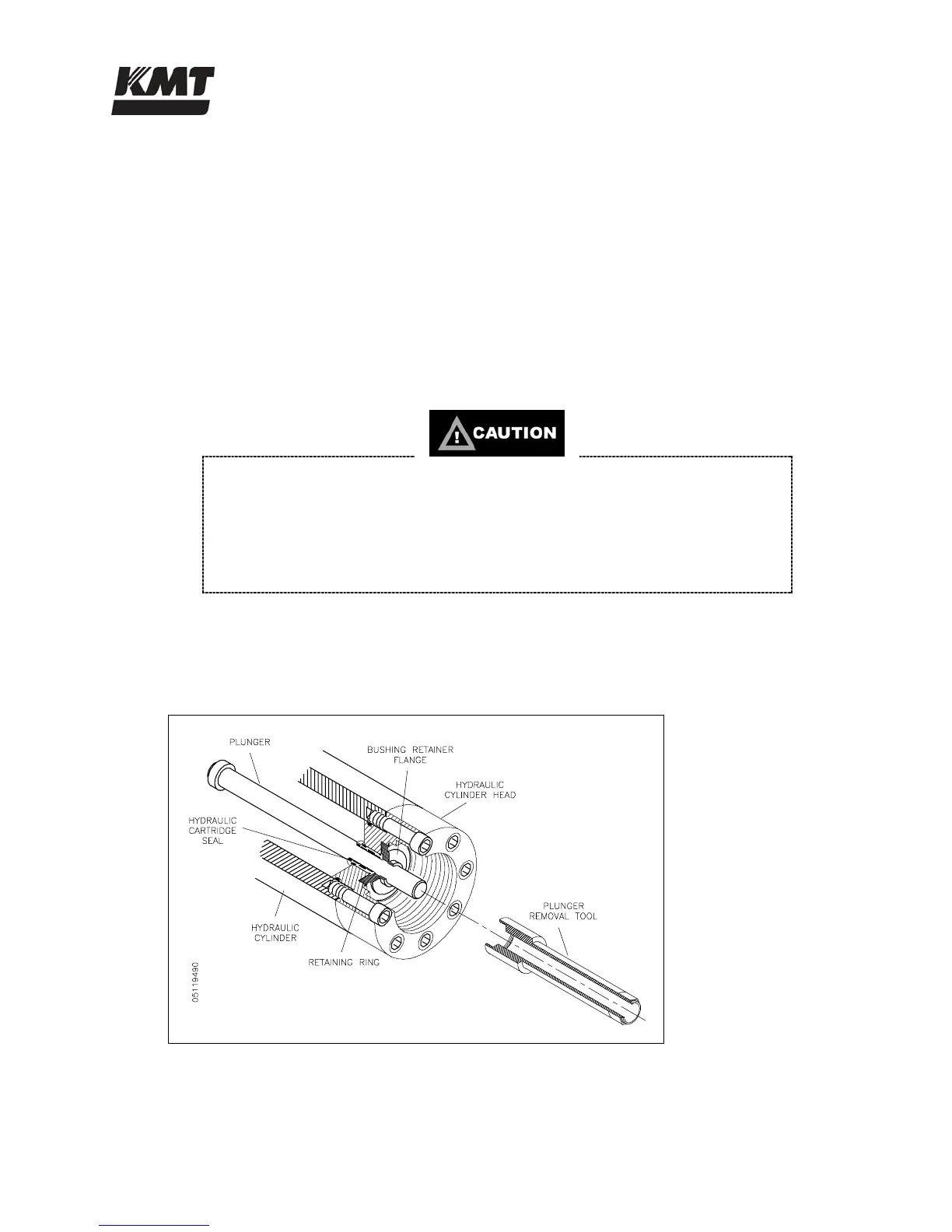

5. Use a flat screwdriver to remove the retaining ring from the hydraulic cylinder head.

6. Remove the bushing retainer flange and clean the surfaces, weep holes and grooves.

Check the retainer flange for cracks.

7. Replace the proximity switch by positioning the o-ring spacer and the switch. Apply

JL-M grease to the threads on the socket head screws and tighten, following the torque

specifications in Table 8-1.

It is recommended that the proximity switch be reinstalled as soon as practical.

Removal of the switch presents the potential of an oil spray hazard.

Ensure that the proximity switch is properly installed and secured prior to starting

the machine. Failure to tighten the two hold down screws on the switch will result

in the spray of hydraulic oil.

8. Thread the large end of the plunger removal tool onto the hydraulic cartridge seal and pull

the cartridge out, over the plunger.

Figure 8-14: Hydraulic Cartridge Seal Removal

9. With the cartridge removed, the plunger can now be removed with the hydraulic cylinder

head in place. The plunger is held in position by six retainer pins. The pins close around

the plunger button to retain the plunger, and retract to release the plunger.

Loading...

Loading...