3 Device Profile

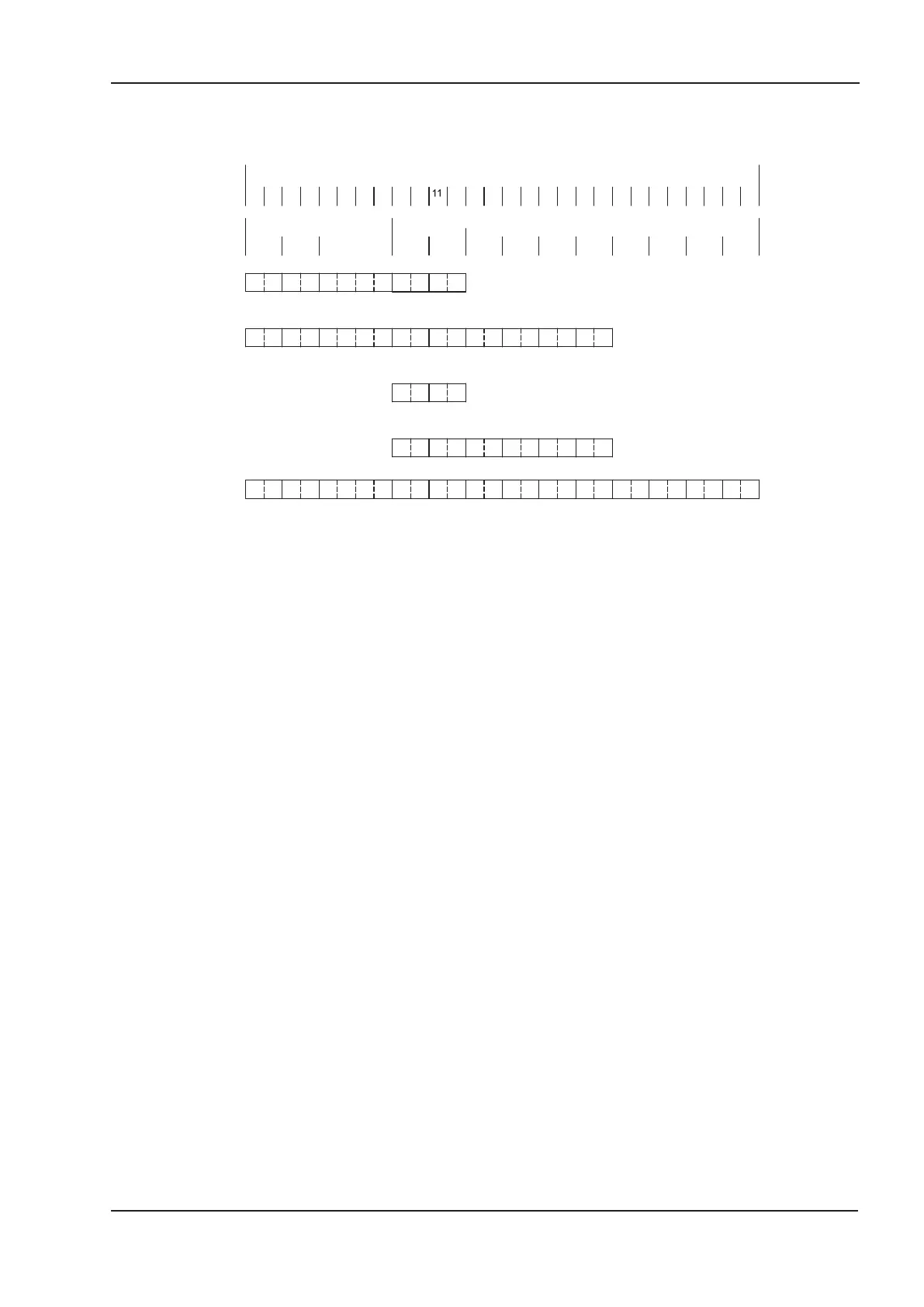

The PROFIBUS profile PROFIDRIVE includes the following parameter process-data objects (PPO):

The servo amplifier only uses the PPO-type 2 (with 4 words PKW-section and 6 words PZD-sec-

tion). The PKW-section is used mainly for the transmission of parameters for the servo amplifier,

the PZD-section is used principally for handling motion functions.

The telegram can be divided into two sections or data channels:

1. PKW-section (4 words, Bytes 1 to 8)

2. PZD-section (6 words, Bytes 8 to 20)

The PKW data channel can also be termed the service or parameter channel. The service channel

only uses confirmed communication services, and is used by the servo amplifier as a parameter

channel.

The PKW channel has no real-time capability.

The PZD data channel can also be termed the process data channel. The process data channel

uses unconfirmed communication services. The response of the servo amplifier to an unconfirmed

service can only be seen in the reaction of the amplifier (status word, actual values).

The PZD channel has real-time capability.

PROFIBUS for S300/S400/S600/S700 17

Kollmorgen 04/2017 Device Profile

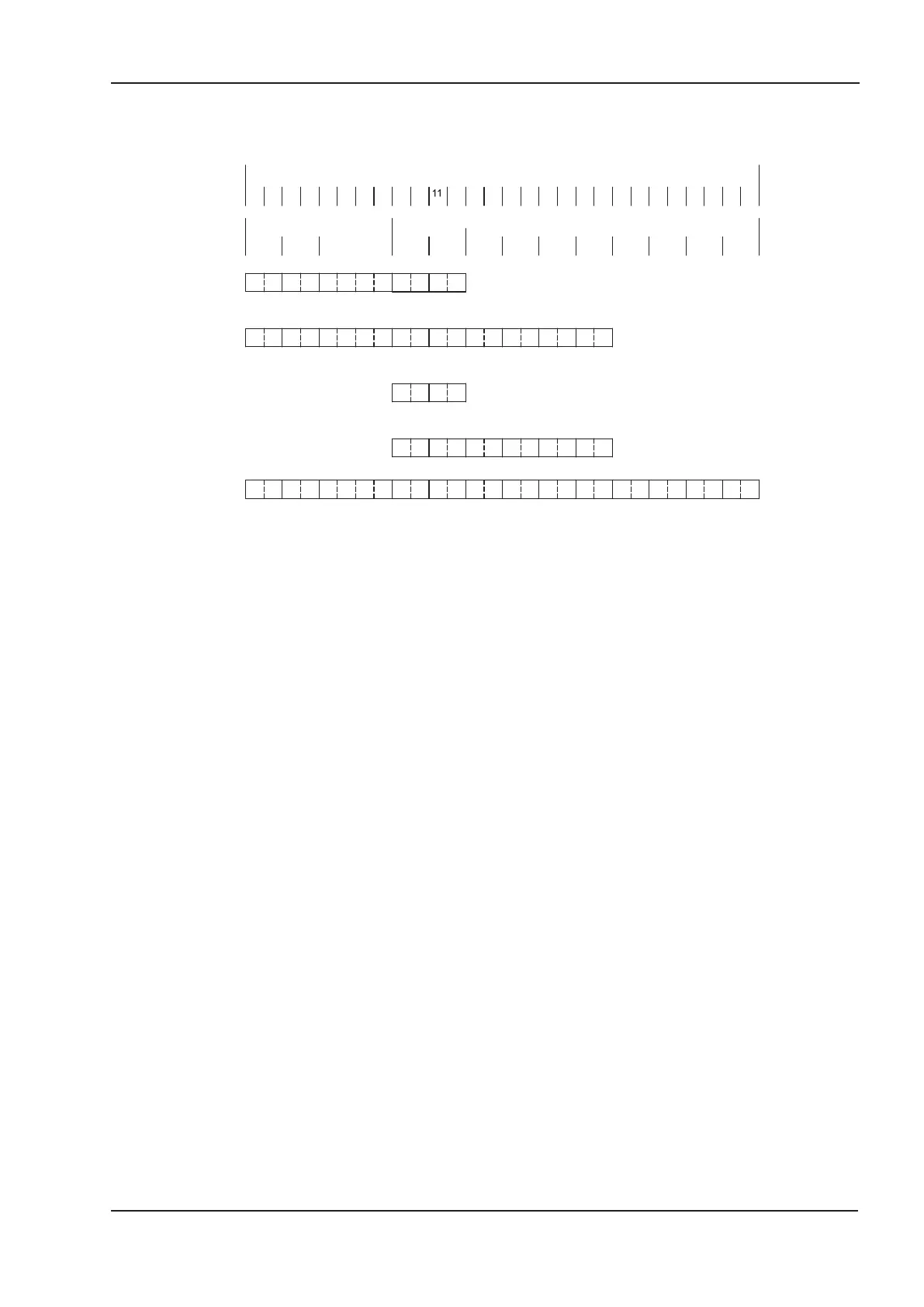

PKW

PKE IND PWE

PZD

STW

ZSW

HSW

HIW

PZD1 PZD2 PZD3 PZD4

Typ 1 : Octet-String 12

Typ 2 : Octet-String 20

Typ 3 : Octet-String 4

Typ 4 : Octet-String 12

PKW:

PKE:

IND:

PWE:

PZD:

STW:

ZSW:

HSW:

HIW:

12 3 45 678910

12 13 14 15 16 17 18 19 20

BYTE

Typ 5 : Octet-String 28

PZD6 PZD7PZD5 PZD8

21 2322 24 272625 28

PZD9 PZD10

4th octet reserved

Abbreviations

Parameter ID value

Parameter ID (1st and 2nd octet)

Index with PPO (3rd octet)

Parameter value (5th to 8th octet)

Control word

Status word

Main setpoint

Main actaul value

Process data

Loading...

Loading...