4 Parameter channel (PKW)

The digital servo amplifiers of the servo amplifier series have to be adapted to the circumstances of

your machine. The parameters for the controllers are set using either the setup software or via the

PROFIBUS.

4.1 Read/write an amplifier parameter

Read (AK = 1) or write (AK = 3) amplifier parameters

To read or write an amplifier parameter through PROFIBUS, the corresponding PNU must be used.

The parameters that are written to the servo amplifier can be transferred to the non-volatile memory

by using the command “non-volatile parameter save” (PNU 971).

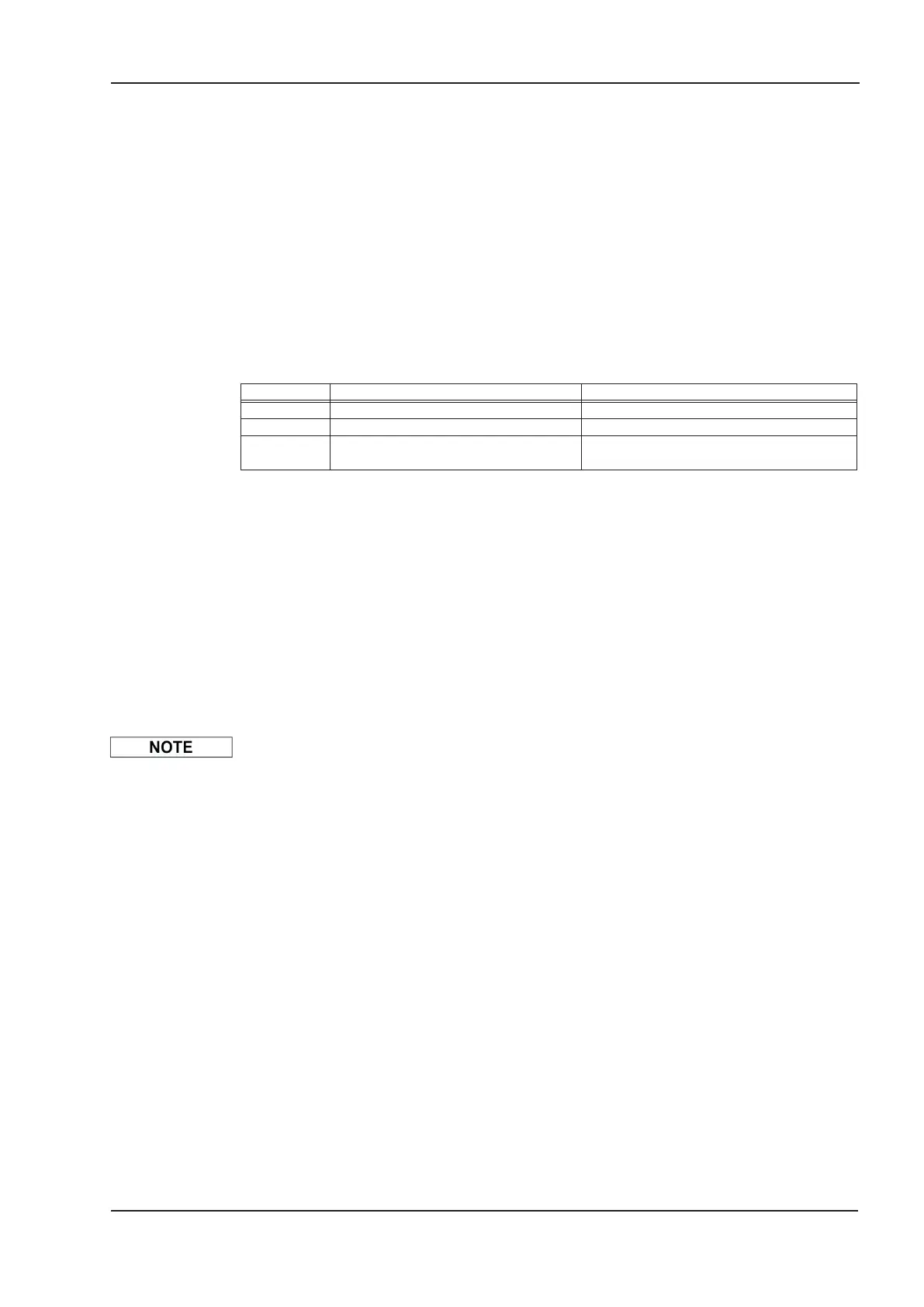

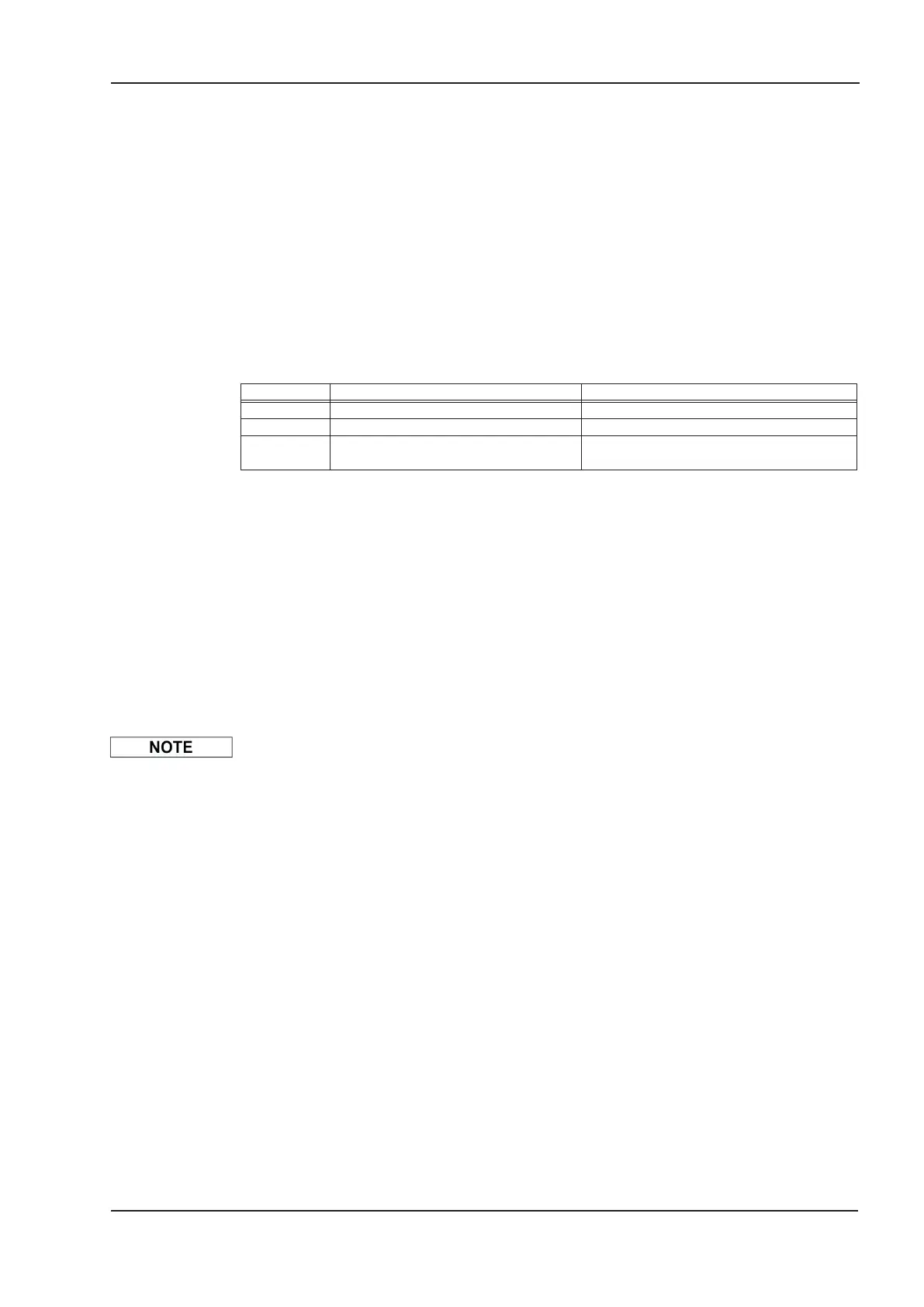

Telegram layout:

Request Response

PKE/AK 1 (read) / 3 (write) 2 (OK) / 7 (error)

PKE/PNU see 4.2.1 as transmitted

PWE

for AK = 3 see p.22ff for data type

for AK = 1 data type irrelevant

for AK = 3 returns the PWE of the request

for AK = 1 see p.22f for data type

4.2 Summary of the parameter numbers

All the parameter numbers (PNUs) for the servo amplifier are listed in numerical order in the table

on page 22ff, with a short description. The parameter numbers in the range 900 – 999 are pro-

file-specific for the PROFIBUS drive profile PROFIDRIVE. Parameter numbers > 999 are manufac-

turer- specific.

For better understanding, you can look up the ASCII commands which are in the column “ASCII

command” in the online help the setup software. A description of all ASCII commands can be found

in the ASCII reference lists (referring to the servo amplifier type) located on the product CDROM

and on our website.

Parameter numbers >1600 use the object channel (see p.33ff).

In the S400/S600 some amplifier parameters (e.g. GV) have 2 PNU numbers. Both of them can be

used to read and write the parameter (e.g. PNU 1200 and PNU 1672).

PROFIBUS for S300/S400/S600/S700 21

Kollmorgen 04/2017 Parameter channel (PKW)

Loading...

Loading...