6.1.3 Enable the servo amplifier

The hardware enable signal (24V) must be applied, as a precondition for enabling the servo ampli

-

fier via the PROFIBUS. The enable through PROFIBUS can be made by setting the bit combination

for the “Operation enabled” state in the control word (STW).

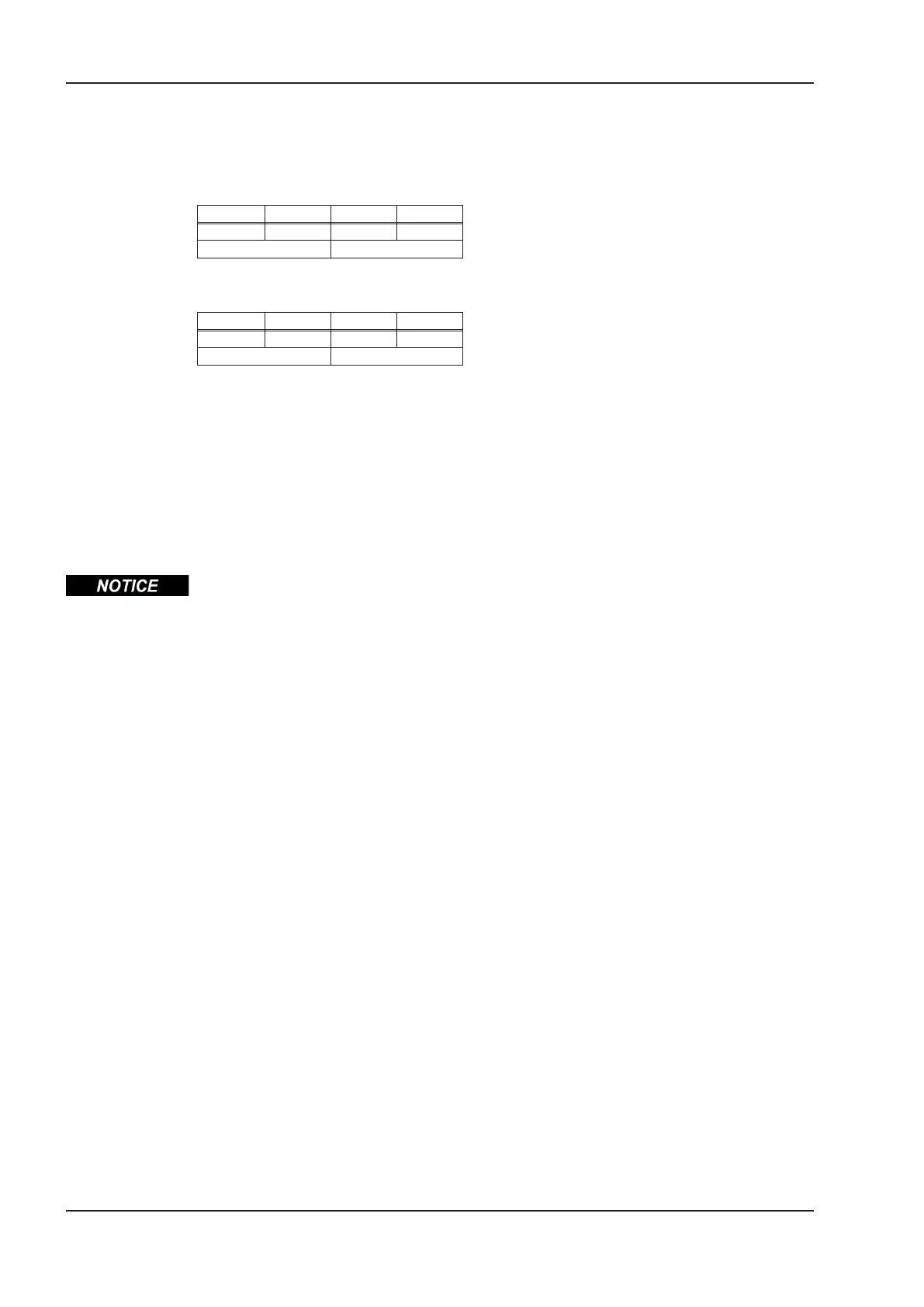

Byte 9 10 11 12

xxx0 x1xx 0011 1111 xxxx xxxx xxxx xxxx

STW HSW

The servo amplifier then reports back the corresponding state in its status word (ZSW), or indicates

a warning or error message.

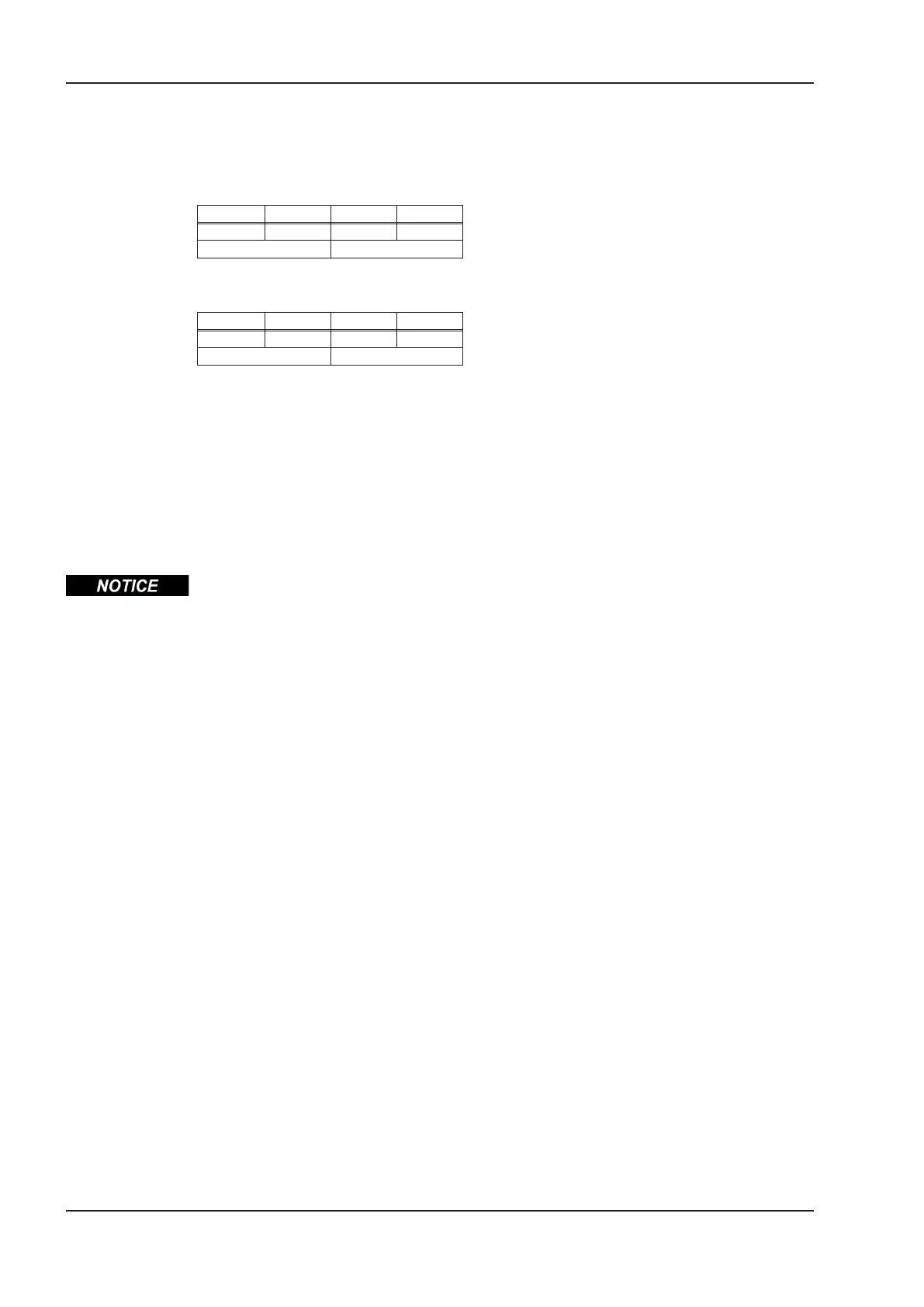

Byte 9 10 11 12

xxxx xx1x 0010 0111 xxxx xxxx xxxx xxxx

ZSW HSW

6.1.4 Start jog mode (on positioning opmode)

Jog mode is started in a similar manner to homing. To start, Bit 8 STW must be set. The jog velocity

is given by the product of the 16-bit main setpoint in PZD2 and the multiplier defined by PNU 1894.

The sign of the main setpoint determines the direction of movement.

It is not necessary to have a reference point set for jogging.

6.1.5 Set reference point

Take care that the position of the reference point permits the following positioning operations. The

parameterized software limit-switches in the servo amplifier may not be effective. The axis could

then drive up to the hardware limit-switch or the mechanical stop. There is a danger of damage

being caused.

The control word (STW) Bit 12 = 1 defines the present position as being the reference point. The

positioning functions are enabled. The shifting of the zero point (NI-offset) is ineffective.

The replay “Reference point set” is made through Bit 17 in the manufacturer-specific status register

(PNU 1002) or Bit 1 (manufacturer status of the process data).

Conditions:

PNU930 ¹ -16

No motion function active manufacturer specific status, process data 5 bit 0

46 PROFIBUS for S300/S400/S600/S700

Appendix 04/2017 Kollmorgen

Loading...

Loading...