7.1.7 Start a motion task

Motion tasks are started by a transition edge (positive or negative) at Bit 6 STW. Bit 14 STW is

used to decide whether a stored motion task or a direct motion task should be carried out.

Conditions:

Hardware enable is present.

Amplifier is in the “Operation enabled” state.

For linear axis: reference point is set.

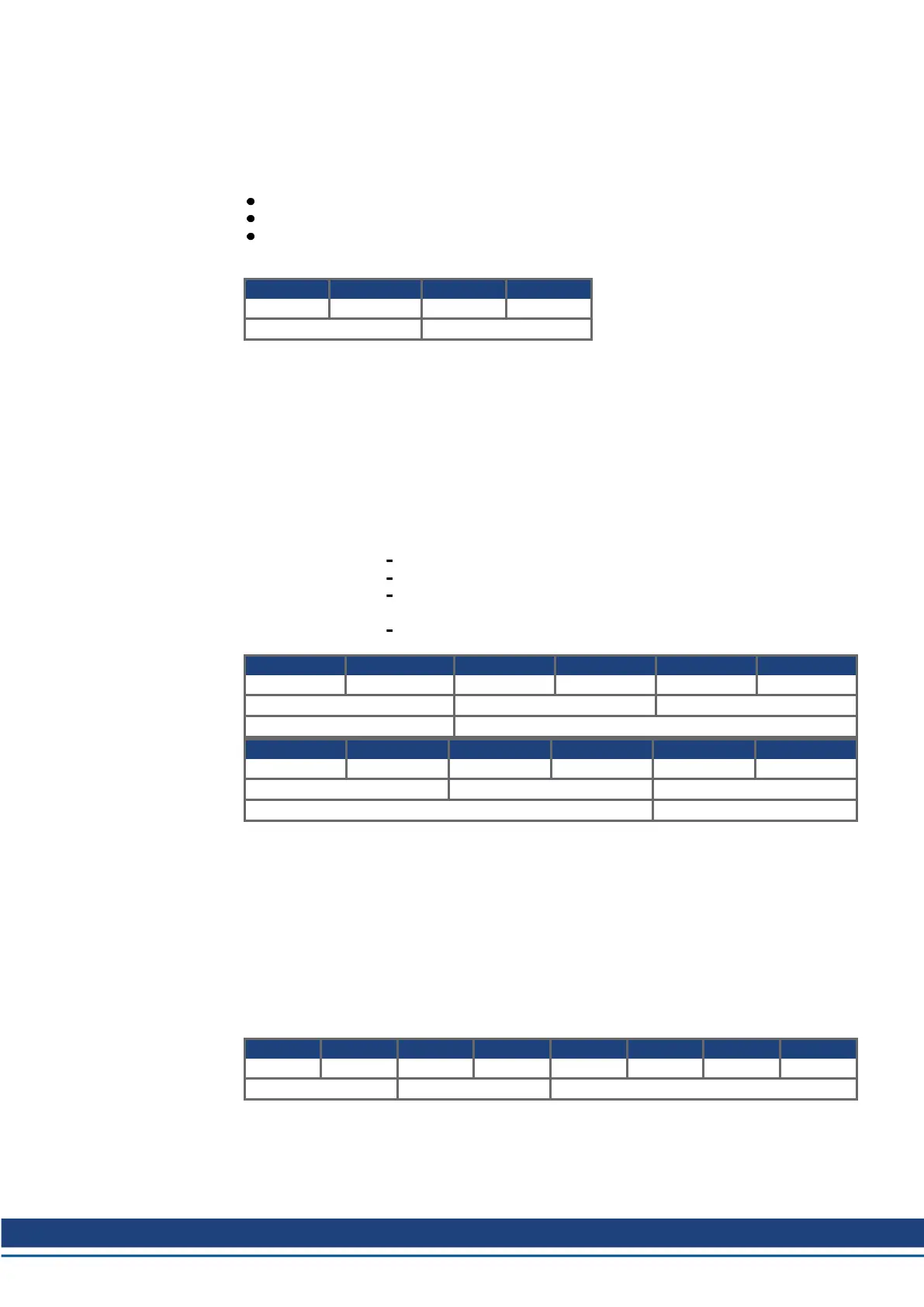

Example: start the EEPROM motion task number 10:

Byte 9 10 11 12

0000 0100 0F*11 1111 0000 0000 0000 1010

STW HSW

* F stands for a transition edge, the state of Bit 6 STW also depends on the previous state.

By setting bit 5 in the manufacturer specific status, the amplifier indicates that it has accepted the

motion task and is carrying it out.

7.1.8 Start a direct motion task

If the motion task data is to be directly sent from the controller, then a direct motion task must be

used. In this case, the target position, velocity and type of motion task are transferred using the

process data channel (PZD), together with the call of the motion task. If required, further para-

meters for this motion task (e.g. ramps) can be transferred previously by parameter tasks.

Target position 35000 µm

Velocity 20000 mm/s

Motion task type relative to actual position

with following motion task without pause

target velocity for the following task should already be reached at the tar-

get position (only makes sense if there is no change of direction)

use SI (user) units

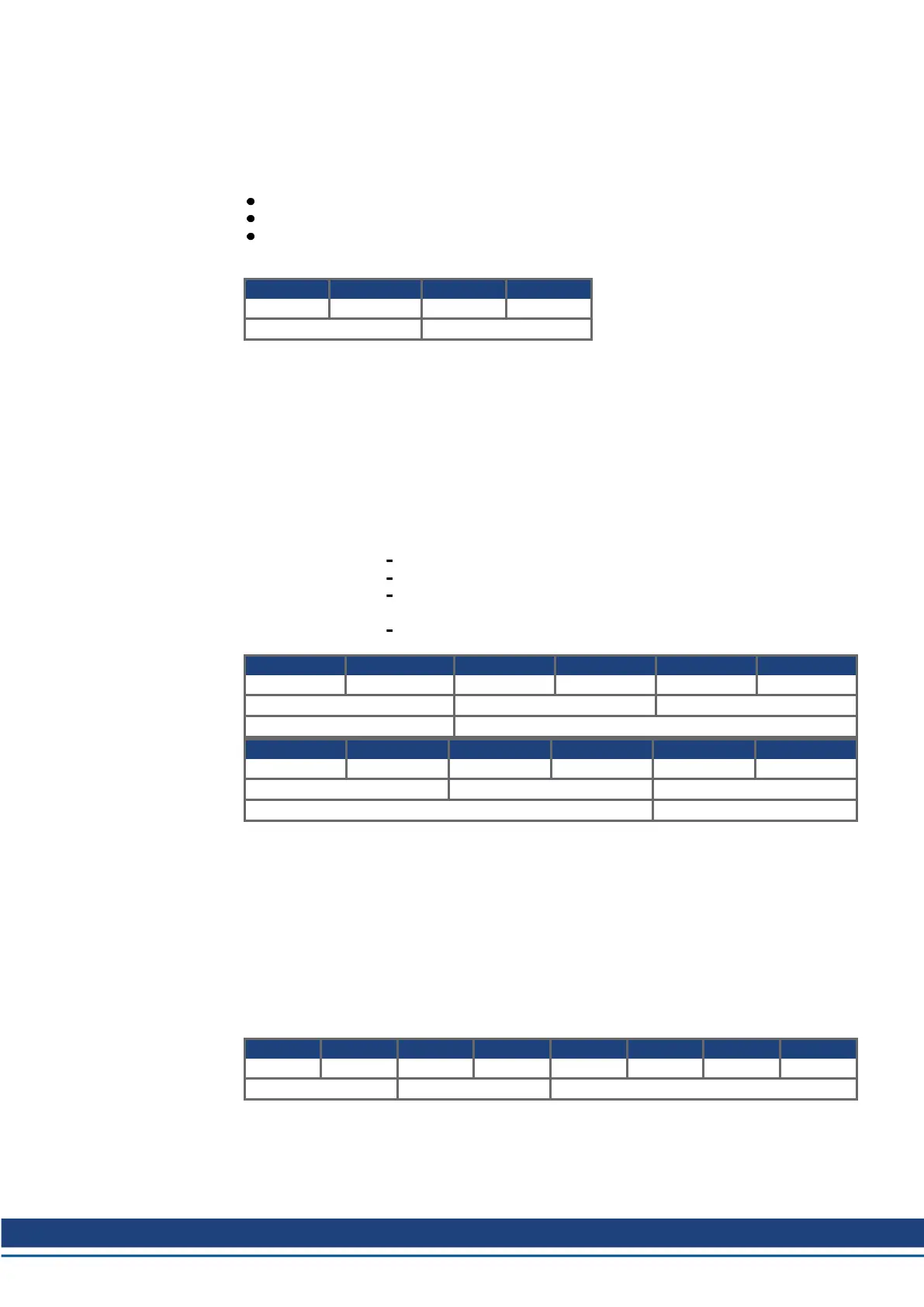

Byte 1 2 3 4 5 6

0100 0100 0F*11 1111 0000 0000 0000 0000 0100 1110 0010 0000

PZD1 PZD2 PZD3

STW velocity setpoint

Byte 7 8 9 10 11 12

0000 0000 0000 0010 0000 1111 0101 1000 0010 0001 0001 1101

PZD4 PZD5 PZD6

position setpoint motion task type

* F stands for a transition edge, the state of Bit 6 STW also depends on the previous state.

7.1.9 Polling a warning or error message

If a warning or error message is present, then parameter 1001 or 1002 can be interrogated to find

out the number of the warning or error.

7.1.10 Writing a parameter via parameter channel

Parameter v_max is used as an example to show how control parameters are transmitted from the

master to the servo amplifier.

Parameter number: 1816 111 0001 1000

Parameter value: 350000 µm/s 0000 0000 0000 0101 0101 0111 0011 0000

Byte 1 2 3 4 5 6 7 8

0011 0111 0001 1000 0000 0100 0000 0000 0000 0000 0000 0101 0101 0111 0011 0000

PKE IND PWE

Note: After an error has occurred in parameter transmission (AK = 7), a “Zero telegram” should be

transmitted, i.e. the first 8 bytes of the transmit telegram from the PLC should be kept at 0, until the

servo amplifier has responded with a zero telegram.

S300-S400-S600-S700 PROFIBUS | 7 Appendix

Kollmorgen | kdn.kollmorgen.com | December 2019 49

Loading...

Loading...