Vers. 062721 74

utilizing the MODBUS TCP protocol for screwdriver control, program switching, and data

acquisition.

Changing program parameters such as target torque via MODBUS is possible but not

recommended, and is never necessary except for the rare applications requiring more than

64 different programs.

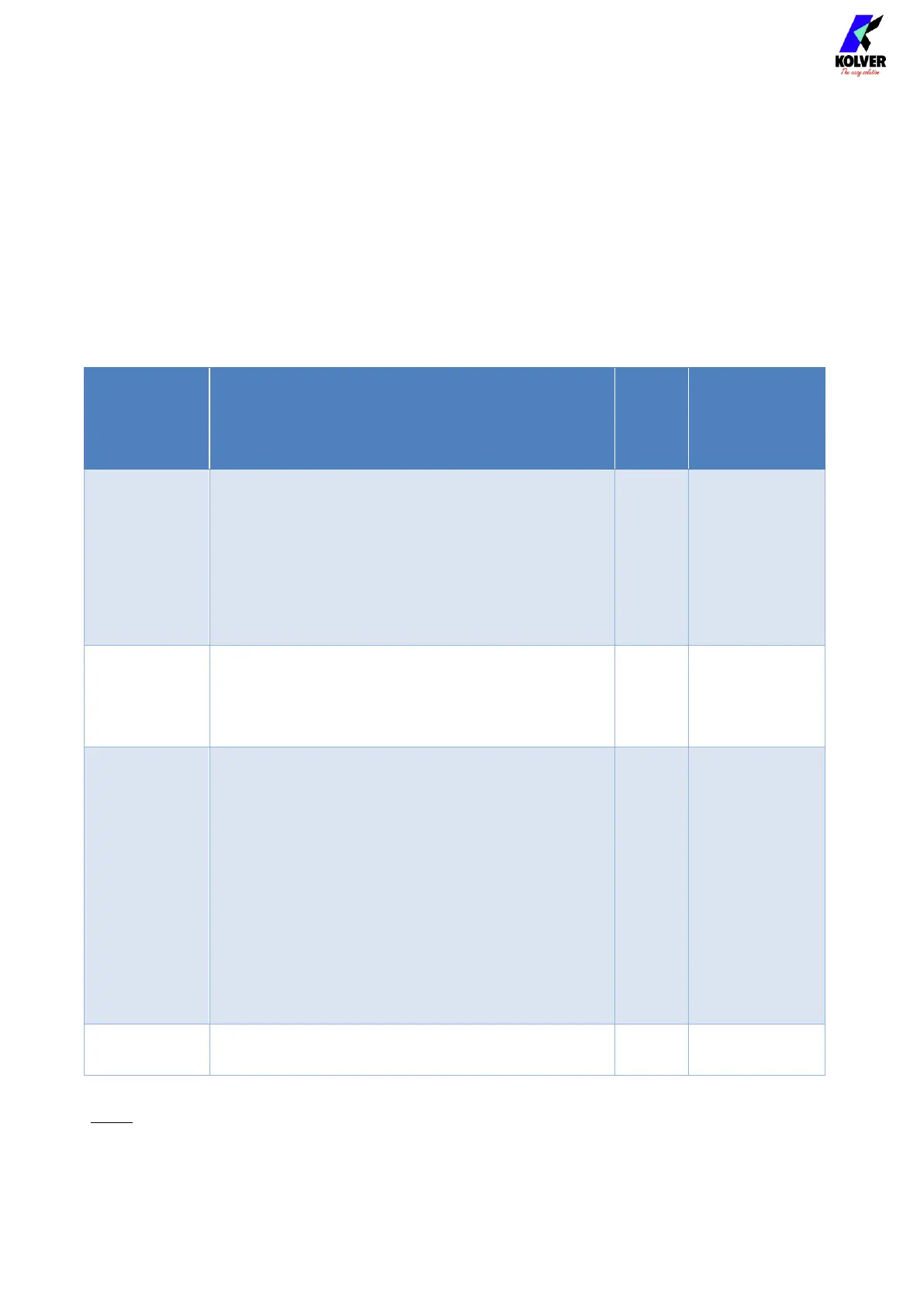

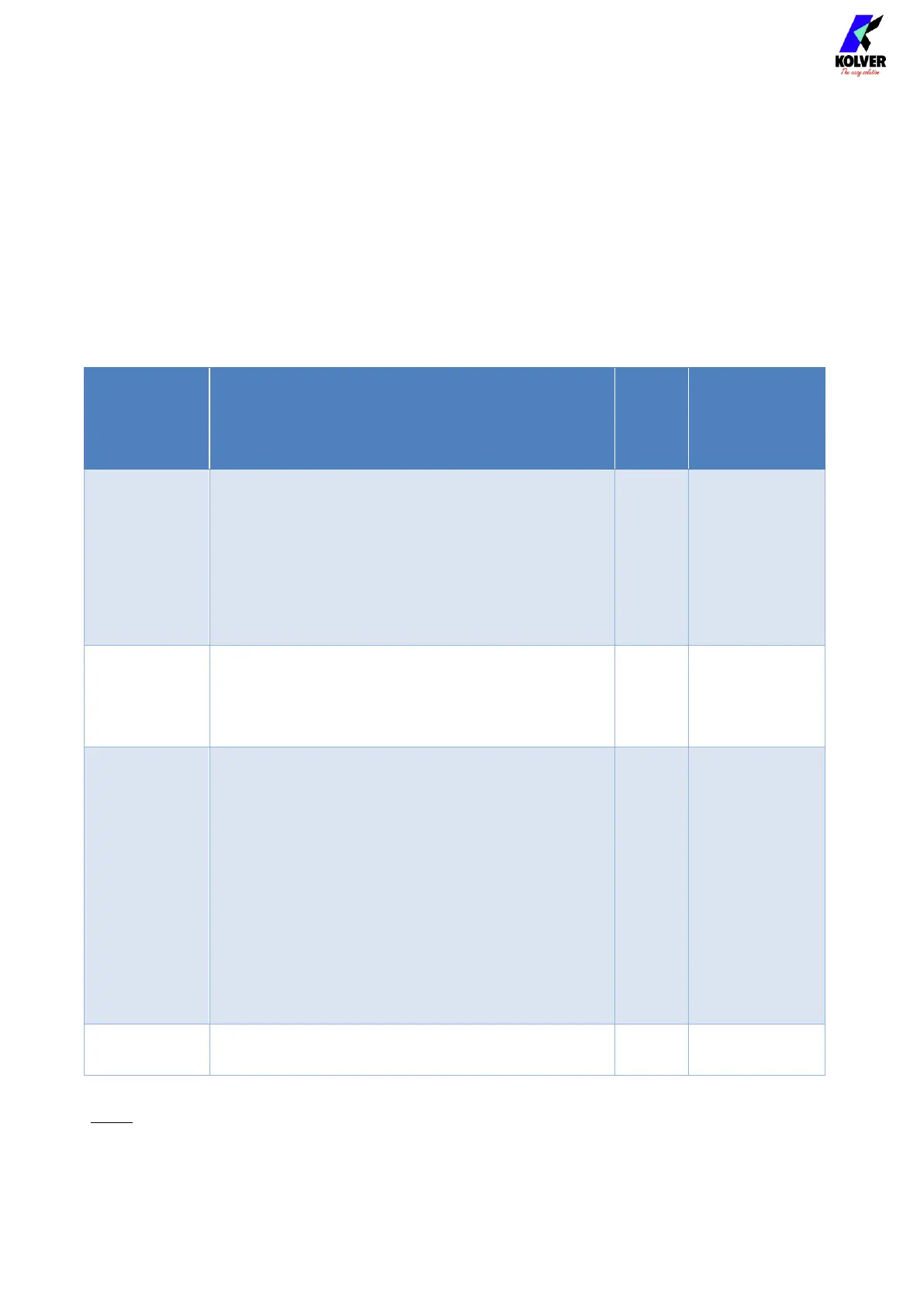

K-DUCER MODBUS map

The K-DUCER, MODBUS data is organized and accessed as follows:

Associated

MODBUS

function

codes

A mirror copy of the CN3 output pins 23 to 43

represented as bits;

Writeable coils mimicking the functionality of

CN3 input pins 13 to 20, providing

screwdriver motor control capability

01 (read coils)

05 (write

single coil)

15 (write

multiple coils)

Data related to the last screwdriving results

including closing torque and angle;

torque/angle charts; current screwdriving state

and errors; connected screwdriver info

04 (read input

registers)

HOLDING

REGISTERS

(bytes)

Current selected program;

Remote programming mode enter/exit flag;

All program settings;

All sequence setting;

Current selected sequence;

All options settings.

03 (read

holding

registers)

06 (write

single

register)

16 (write

multiple

registers)

A mirror copy of the CN3 input pins 1 to 20

represented as bits

*Note: all holding registers except CurrentProgram (7373) can only be written after entering

Remote Programming Mode. These registers contain all program, sequence, and option

Loading...

Loading...