V - 19

Basic Settings and Operation

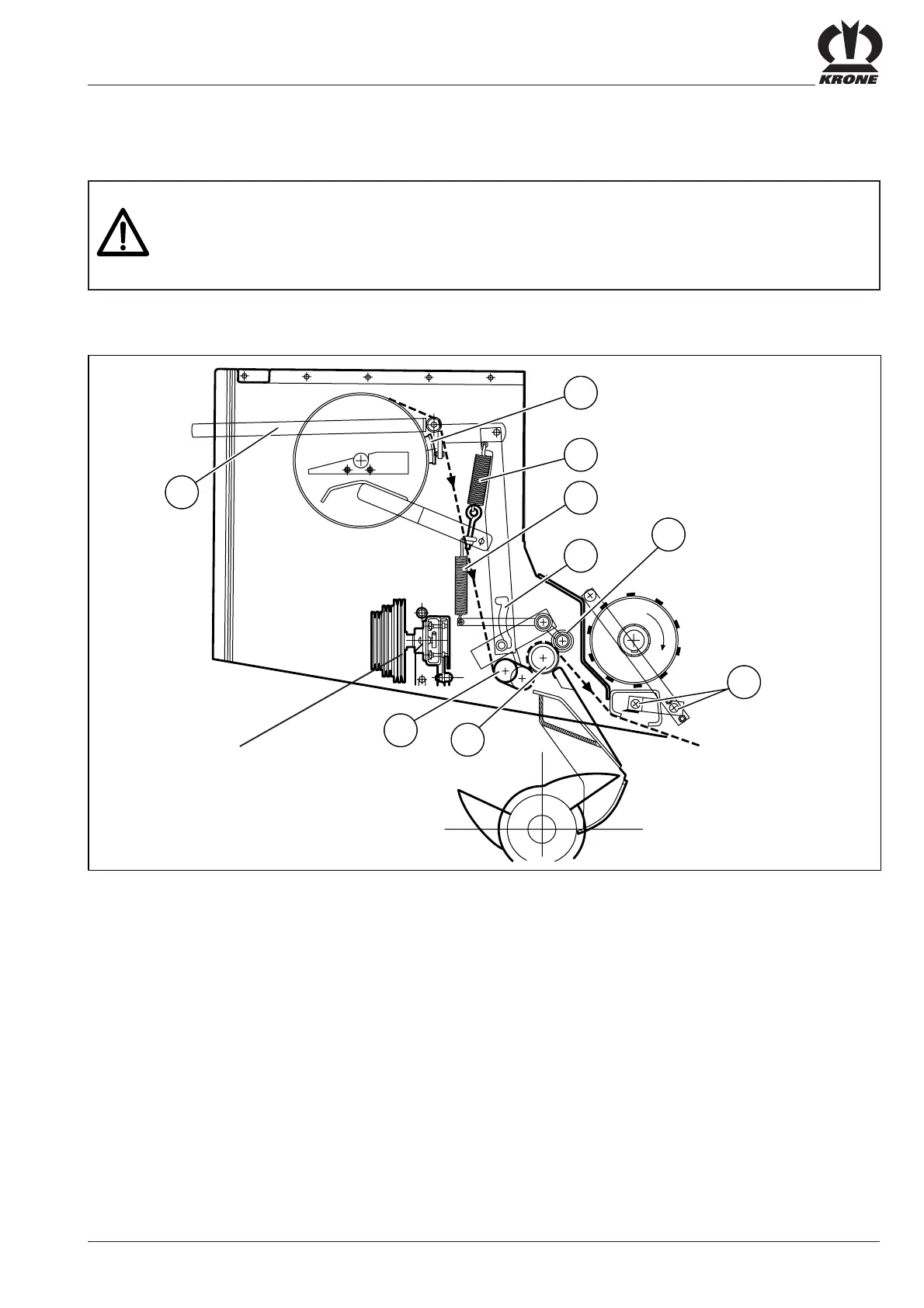

RBV00212

6

9

2

8

3

1

7

5

4

5.7 Net Wrapping

5.7.1 Special Safety Instructions

The following general rules apply to all maintenance, assembly, repair and adjustment work:

• Bring the round baler to a complete standstill.

• Switch off the motor, remove the ignition key and disconnect the 12 V supply voltage.

• Secure the tractor and round baler against rolling.

5.7.2 Components

1 cutter bar

2 connecting link guide

3 pressure roller

4 rubber-coated roller

5 net stretcher bar

6 net brake spring

7 brake lever

8 net brake

9 pressure roller spring

5.7.3 General Information

The netting is threaded from the net roll over the guide

shaft to the net stretcher bar (5); from there it is

threaded between the rubber-coated roller (4) and the

pressure roller (3) into the cutter bar area (1). When

the wrapping process begins, the rubber-coated roller

(4) feeds the netting into the feed channel and the

rotating round bale. The netting is picked up by the

round bale along with the baling material. The round

bale pulls the netting from the netting roll over the

rubber-coated roller (4) and the net stretcher bar (5)

by self-rotation. The netting is kept taut by the net

brake (8) throughout the rapping process. Following

the wrapping process, the cutter bar (1) is slewed into

the net path and cuts the netting.

twine wrapping

mechanism

(special equipment

for MultiCut)

Loading...

Loading...