2K8

1-4-24

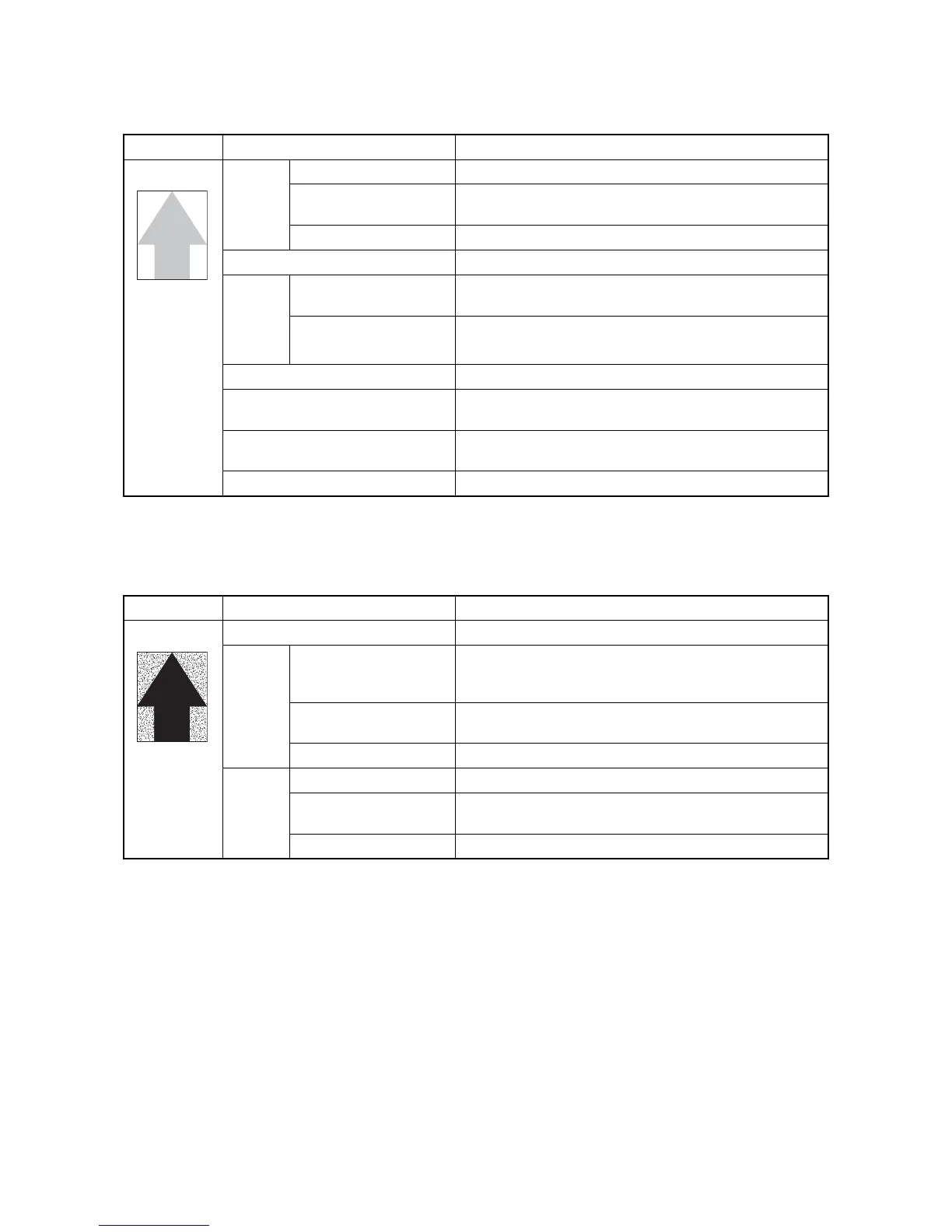

(5) Image is too light.

(6) The background is colored.

Print example Causes Check procedures/corrective measures

Defec-

tive

develop-

ing bias

output.

Defective developing unit. Replace the developing unit for the color that causes an error.

Defective high voltage

PWB.

Replace the high voltage PWB (See page 1-5-34).

Defective engine PWB. Replace the engine (See page 1-5-29).

Dirty drum. Perform the drum surface refreshing (See page 1-3-12).

Defec-

tive

develop-

ing bias

output.

Defective high voltage

PWB.

Replace the high voltage PWB (See page 1-5-34).

Defective engine PWB. Replace the engine (See page 1-5-29).

Defective color calibration. Perform the color calibration (Refer to operation guide).

Insufficient toner. If the display shows the message requesting toner replenish-

ment, replace the container.

Insufficient agitation of toner con-

tainer.

Shake the toner container vertically approximately 10 times.

Paper damp. Check the paper storage conditions, replace the paper.

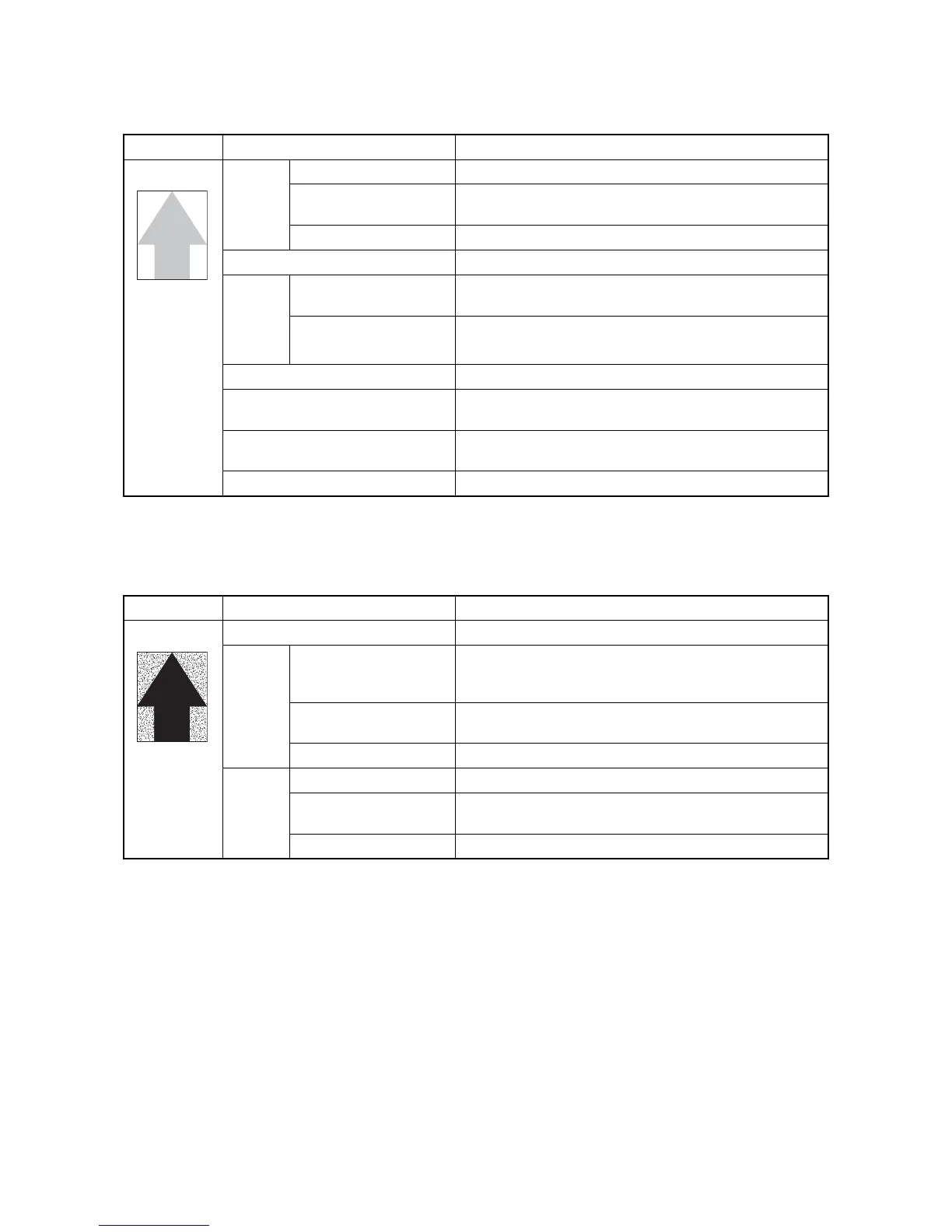

Print example Causes Check procedures/corrective measures

Defective color calibration. Perform the color calibration (Refer to operation guide).

Defec-

tive

develop-

ing bias

output.

Defective developing unit. Check the four colors of image by using the test page of ser-

vice mode. If the defect appears on a particular color, replace

the developer for that color (See page 1-5-12).

Defective high voltage

PWB.

Replace the high voltage PWB (See page 1-5-34).

Defective engine PWB. Replace the engine (See page 1-5-29).

Defec-

tive drum

surface

charging.

Defective drum unit. Replace the drum unit (See page 1-5-14).

Defective high voltage

PWB.

Replace the high voltage PWB (See page 1-5-34).

Defective engine PWB. Replace the engine (See page 1-5-29).

Loading...

Loading...