FLIP

®

01.01.2019

English / Englisch

MAINTENANCE WORK AND REPLACEMENT OF WEARING PARTS

7.8.2 SETTING FOR SPECIAL CASES

In order to achieve a major abrasion at coarse sanding works no

additional pressure must be applied to the attachment! The sanding

pressure and consequently the aggressivity of the abrasive with

the FLIP

®

are adjusted by the guide rollers!

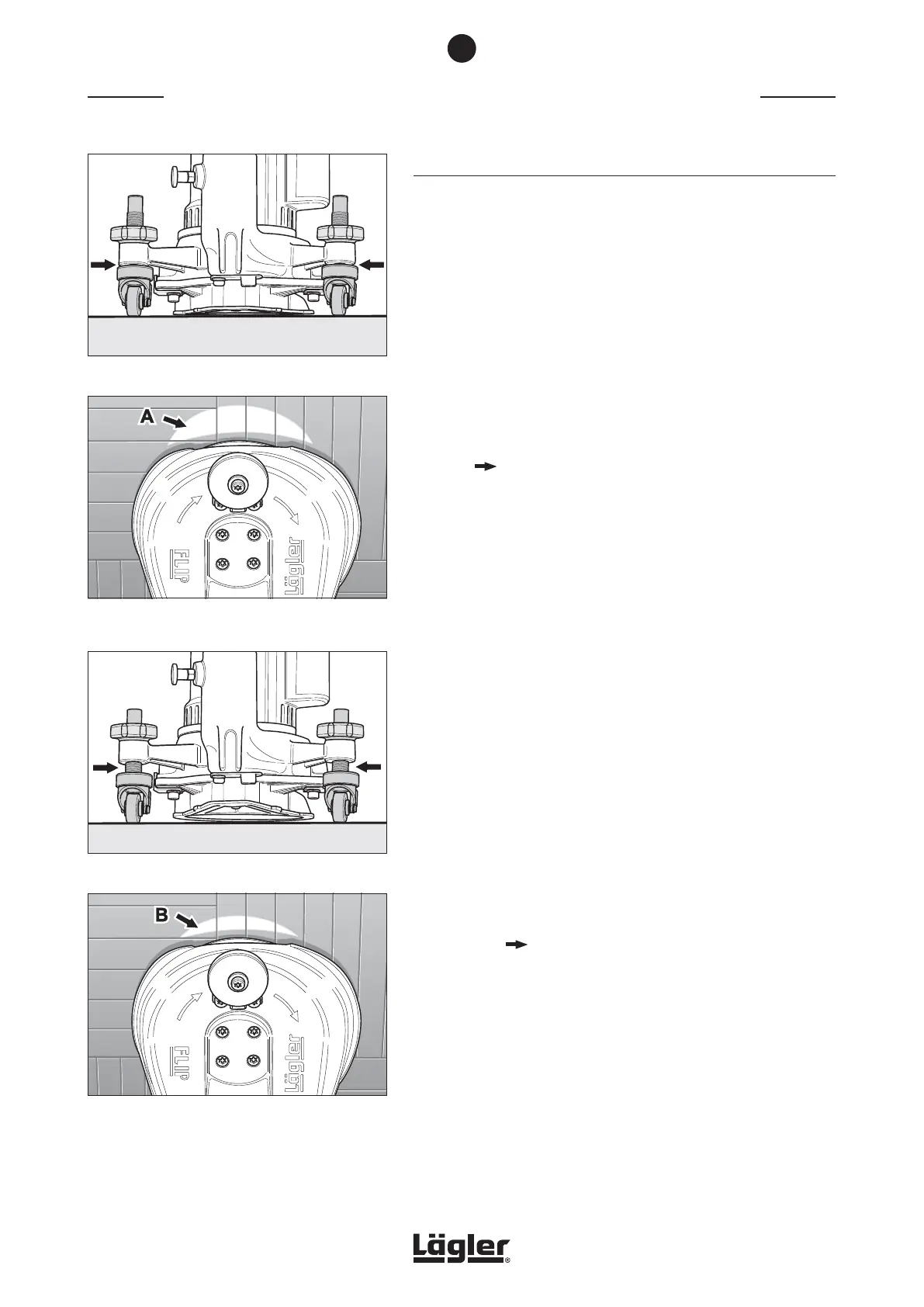

With a flat machine adjustment for fine sanding works (fig. 64)

a larger part of the sanding plate’s surface is touching the floor

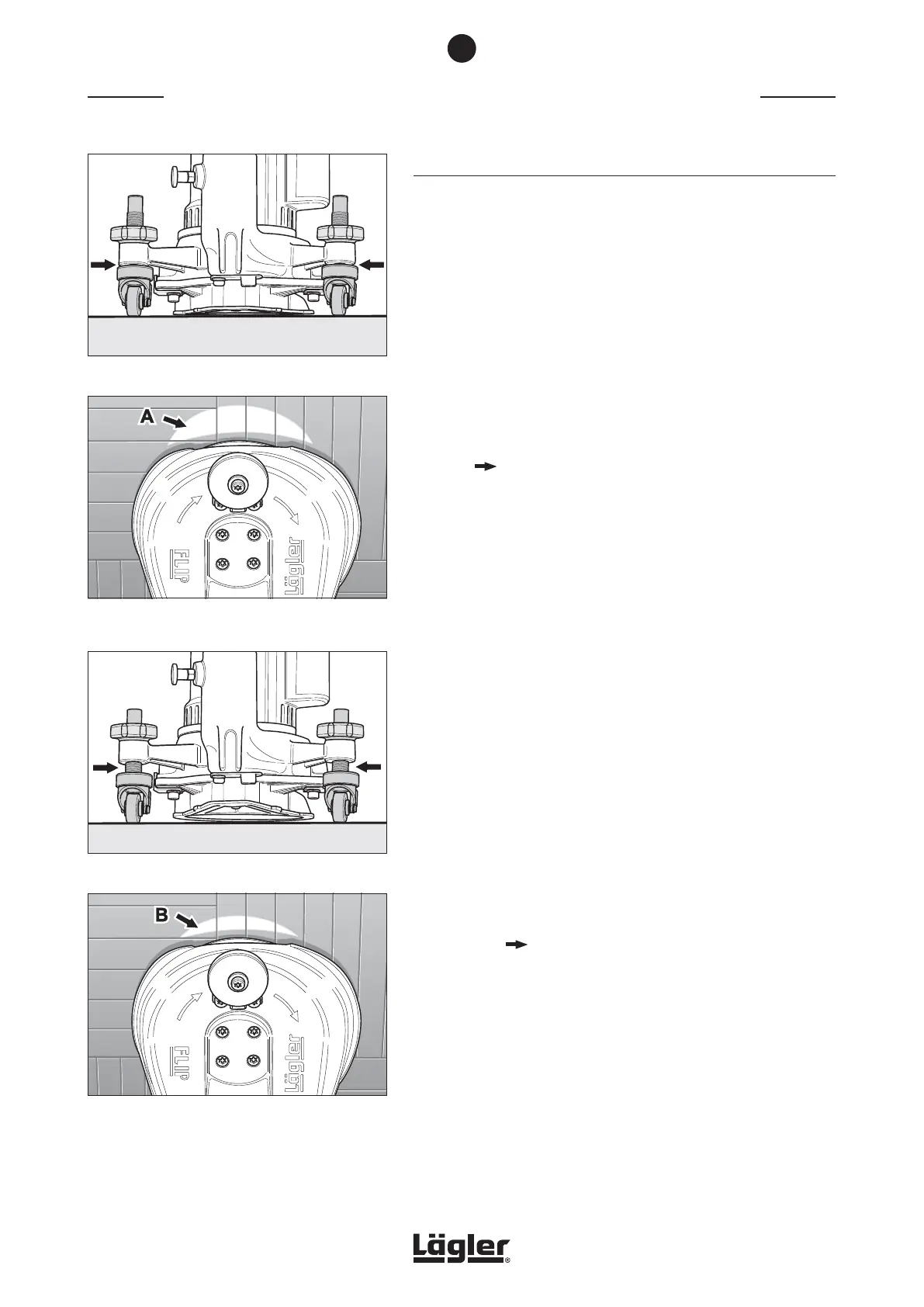

(fig. 65, A) than this would be the case with a steeper machine

adjustment for coarse sanding works (fig. 66 and fig. 67, B).

The steeper the machine adjustment the more aggressive the

abrasive!

The standard setting can easily be restored using the universal

spanner ( Section 7.8.1 , Standard setting).

If you would like a steeper or flatter setting than the standard

setting, proceed as follows:

1 Switch off the machine and pull the power plug out of the

socket!

2 Loosen the locknut of the guide roller to be adjusted

(fig. 56, A).

If the locknut is screwed on too tightly, you can turn the

vertical guide roller axis counterclockwise with the universal

spanner to loosen the locknut (fig. 56, B).

3 Now turn the guide roller one or two rotations in the desired

direction.

4 Retighten the locknut.

5 Adjust the second guide roller.

6 Conduct a trial sanding operation and check the sanding

results ( Section 7.8.1, Standing setting, steps 8 to 10).

7

Fig. 66 Steeper adjustment angle for rough sanding work.

Fig. 64 Flat adjustment angle for fine sanding work.

Fig. 67 Small sanding surface B and therefore major

aggressivity of the abrasive.

Fig. 65 Large sanding surface A and therefore lower

aggressivity of the abrasive.

40

Loading...

Loading...