37

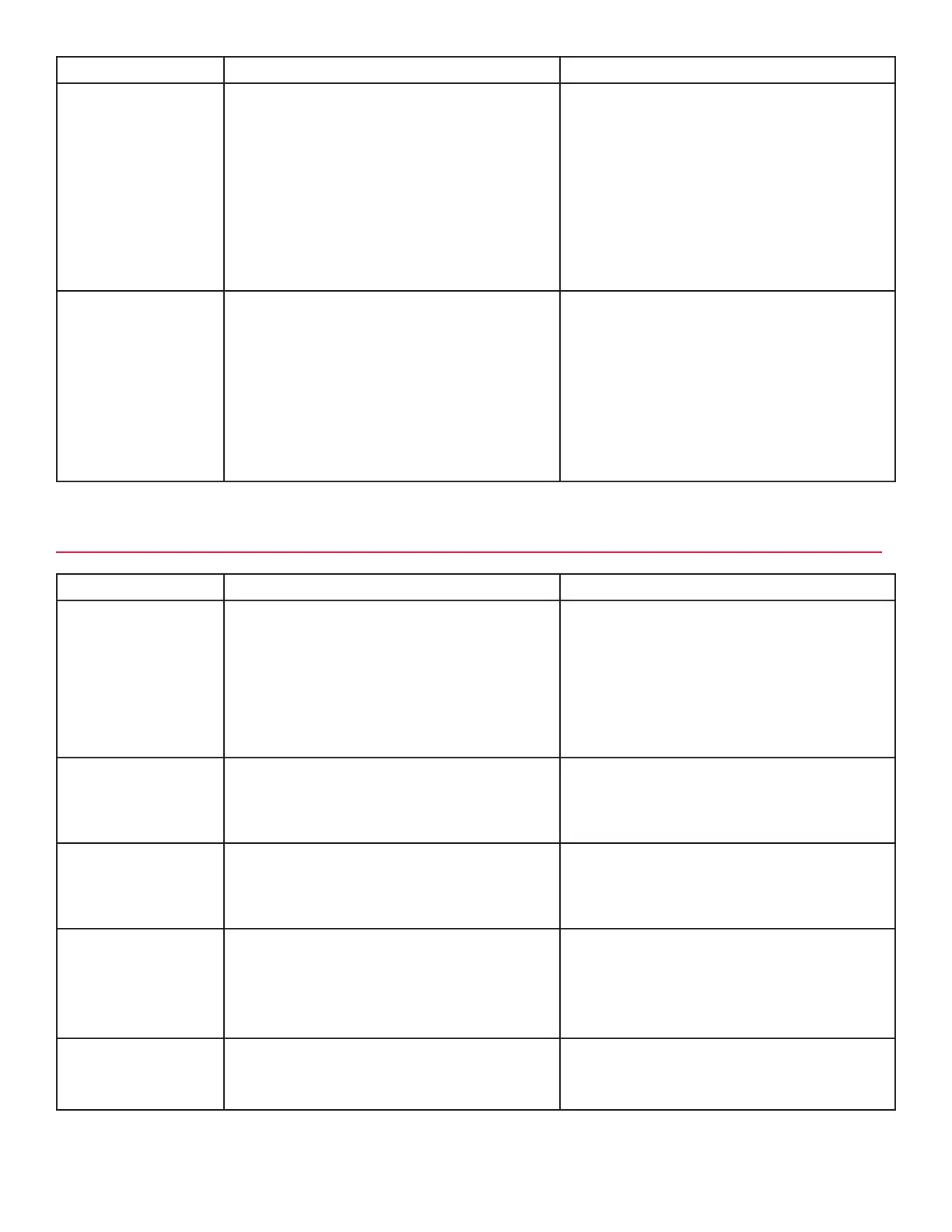

TROUBLE CAUSE REMEDY

Excessive foaming. 1. No ice in bin.

2. Incoming water or syrup temperature too high.

3. CO

2

pressure too high.

4. Water flow rate too high.

5. Nozzle and diffuser not clean.

6. Air in BIB lines.

1. Fill bin with ice and allow coldplate to

restabilize.

2. Correct temperature prior to reaching

dispenser.

3. Adjust CO

2

pressure downward, but not less

than 70 psi (0.483 MPa).

4. Adjust and reset ratio.

5. Remove and clean.

6. Bleed air from BIB lines.

Low or no carbonation. 1. Low or no CO

2

.

2. Low water pressure.

3. Worn or defective carbonator pump.

4. Backflow preventer not allowing water to flow.

5. Probe malfunctioning.

6. PCB malfunctioning.

1. Check CO

2

supply. Adjust CO

2

pressure to 70

psi (0.483 MPa).

2. Need water booster kit.

3. Replace carbonator pump.

4. Replace backflow preventer, noting the flow

direction arrow from pump to coldplate.

5. Replace probe.

6. Replace PCB.

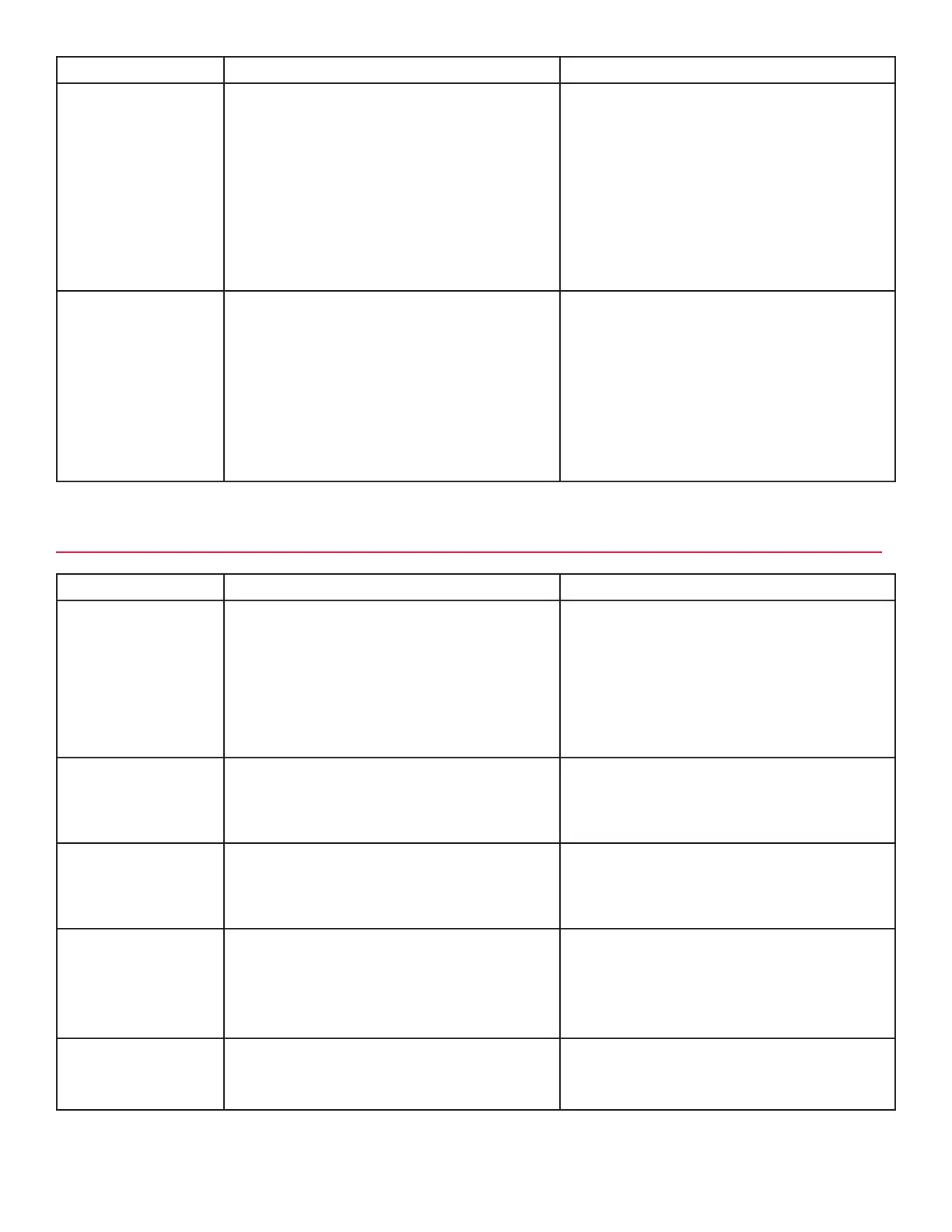

TROUBLE CAUSE REMEDY

Push ice chute; no

response.

1. Dispenser not connected to power source.

2. Key switch in sleep position.

3. Dispenser in sleep mode.

4. Wiring harness not plugged in.

5. PC board defective.

6. Malfunctioning power supply.

1. Connect dispenser to power source.

2. Turn key switch to on position.

3. Touch screen, wait, enter code.

4. Plug in wiring harness.

5. Replace PC board.

6. Check voltage to power supply. Check fuses.

Push chute, ice door

opens but motor does

not run.

1. Wiring harness not plugged in.

2. PC board defective.

3. Motor defective.

1. Plug in wiring harness.

2. Replace PC board.

3. Replace motor.

Push chute, motor runs

but ice door does not

open.

1. Solenoid not connected to PC board.

2. Solenoid defective.

3. PC board defective.

1. Connect solenoid to PC board.

2. Replace solenoid.

3. Replace PC board.

Push chute, ice door

opens, motor runs, but

ice does not dispense,

or ice is of poor quality.

1. Dispenser is out of ice.

2. Agitator pin is missing or damaged.

3. Poor ice quality.

4. Key not installed on agitation shaft.

1. Fill dispenser with ice.

2. Replace agitator pin.

3. Service ice machine.

4. Install key onto agitation shaft.

Noisy/cavitating

carbonator pump.

1. Insufficient incoming water supply pressure. 1. Verify incoming supply water pressure to

carbonator pump is a minimum of 75 psi (0.516

MPa), or maximum of 125 psi (0.862 MPa).

Ice Bin/Ice Chute/Carbonator Pump Troubleshooting

Loading...

Loading...