PLMNL0199 REV. J Effective Date: 08/05/21 15 FiberCUT

®

ST Operation Manual

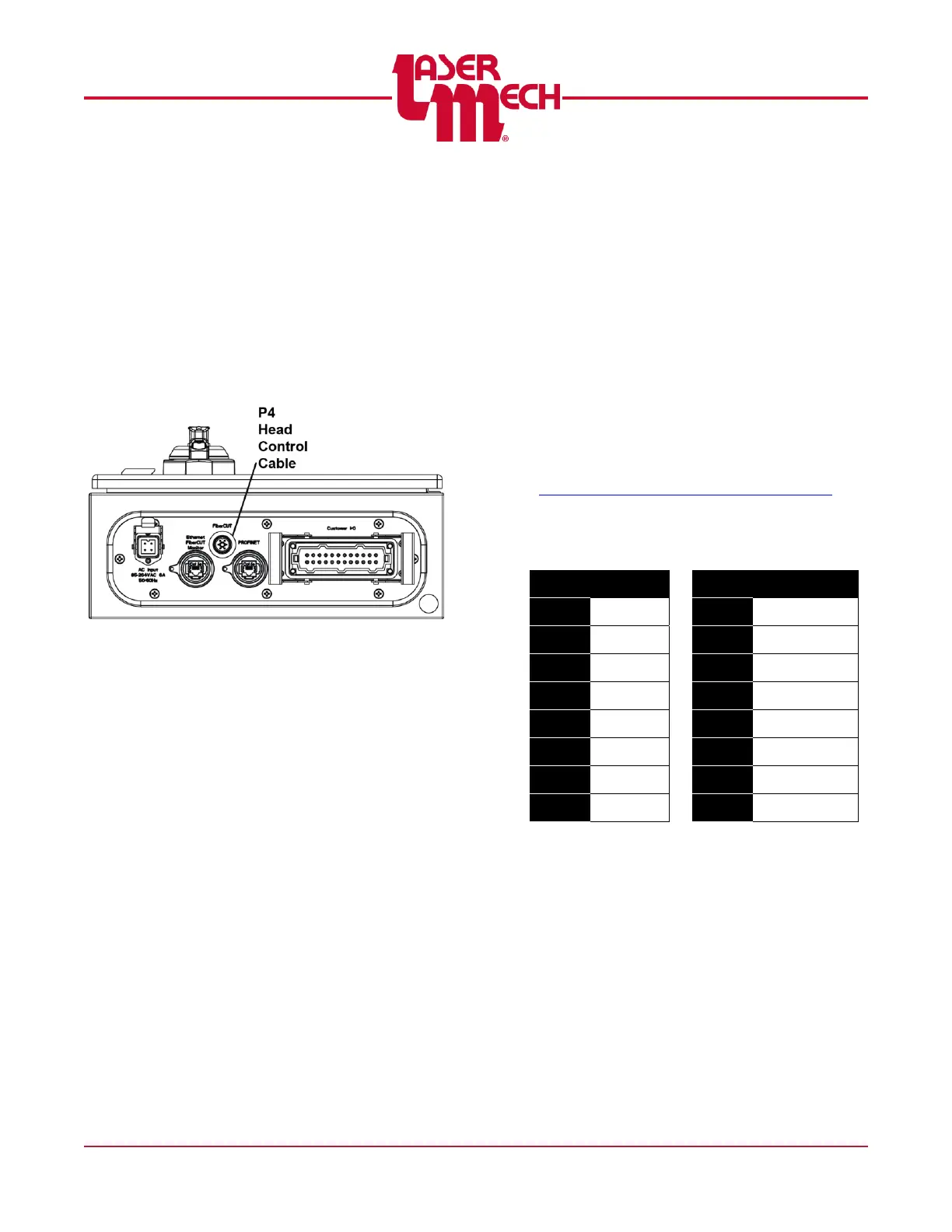

3.8 Head-Control Cable (P4)

A straight through 14-conductor cable

(PLCAB0489) connects the FiberCUT

®

head to the controller. See Figure 18.

Route this cable away from high power and

high voltage wires to prevent interference.

This cable is a high-flex cable designed for

robotic applications, but minimizing the

amount of exposure to movement and

flexing can increase the life of the cable.

Figure 18

3.9 Remote I/O Options

The remote I/O option in the FiberCUT

®

controller simplifies the hardware

integration into the laser processing cell.

Instead of using the discrete I/O

connections in the customer I/O connector,

the integration can consist of a relatively

simple cable. Four different protocols are

available to support most industrial

networks.

Device configuration files (EDS or

GSD) and supplemental manuals are

available for download from the

FiberCUT

®

Updates web page:

http://www.lasermech.com/fibercutupdates

All remote I/O options include the

digital inputs and digital outputs shown

below.

Some controllers also include analog

voltage and temperature readings for

monitoring purposes. Voltages are

reported as 12-bit numbers, where 0-

4095 = 0-5V. Temperatures are

reported as hundredths of degrees

Celsius, where 0-7000 = 0.00-70.00°C.

The (4) sections that follow provide

specific data mappings for each

controller configuration.

Loading...

Loading...