PAVER PREPARATION INSTRUCTIONS

To preventcostly downtime,the pavershouldbechecked

thoroughly before each use. Use

the

list belowto assist

in checking the paver.

1. Checkengine

oil

(see enginemanual), hydraulicoil,

gear

box oil

and

diesel fuel.

2.

Referto

Lubrication Charton

page

25 and lubricate

as specified. (Somearea

orweather

conditions may

require extra lubrication).

3. Check hydraulic

hoses,

fittings, pumpsand motors for

leaks, excessive wear

or

damage.

4. Checkthe engine

safety

switch: (the

engine

should

only

start

when

forward/reverse

levers

are

in the

neutral position.) See figure 2.

5.

Checkallelectricalfunctionsbefo~edistributingasphalt.

6. Sprayfuel oil on any part of

the

paver

that comes in

contact with asphalt.

7. Check burner ignition.

STARTING TO PAVE

GENERAL

The paveris capable of placing bituminous base, binder

and surface courses, lime

or

portland cement stabilized

sub-base and graded aggregate materials up to a thick-

ness of 6 inches. The paverhas a production rate of 250

tons

per

hour.

Equipped with electric and manual thickness controls

and a 8' to 13' wide screed,

the

paver

can

handle everythingfrom drivewaysand smallparking lots

to large parking areas and secondary roads.

Before starting to pave,

keep

the

following points in

mind:

A. Plan the project so

that

the

narrowest

passes

are

first, (the basicwidthof the paver) leaving

the

widest

pass until last.

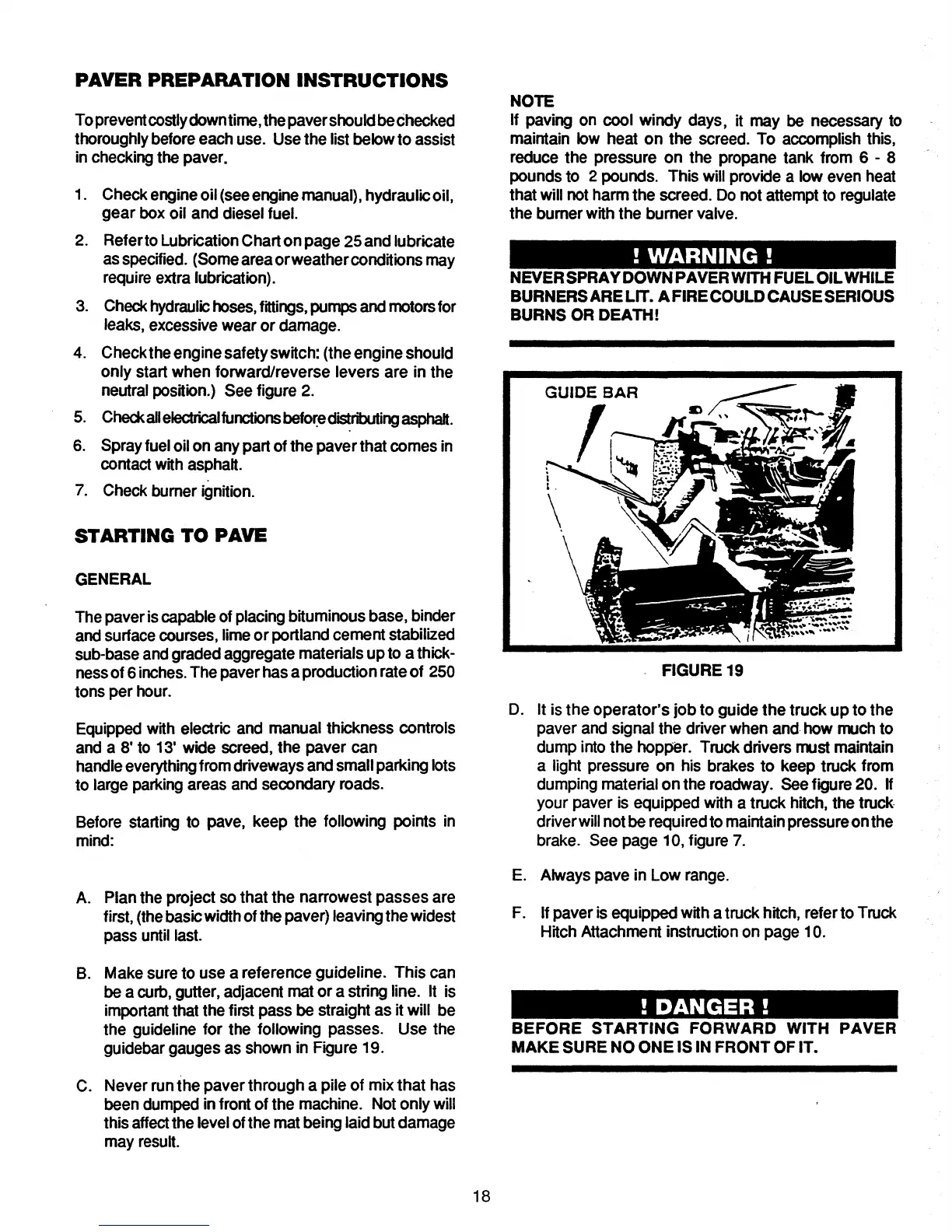

B.

Make

sure to

use

a

reference

guideline.

This

can

be a curb, gutter, adjacent mat

or

a string line. It is

important that the first pass

be straight as it will be

the

guideline

for

the following passes.

Use

the

guidebar gauges as shown in Figure 19.

C.

Never

run

the

paver

through

a pile of

mix

that

has

been dumped in front of the machine. Not

only

will

this affect the level of

the

mat being laid but damage

may result.

18

NOTE

If paving on

cool

windy days, it may be necessary to

maintain low heat

on

the

screed. To accomplish this,

reduce

the

pressure

on

the propane tank from 6 - 8

pounds to 2 pounds.

This

will provide a low even heat

that

will not

harm

the

screed. Do not attempt to regUlate

the

bumer

with

the

burner

valve.

!

WARNING!

NEVER

SPRAY

DOWN

PAVERWITH FUEL

OIL

WH"ILE

BURNERSARE

LIT.

AFIRE COULD CAUSESERIOUS

BURNS OR DEATH!

. FIGURE

19

D. It is

the

operator's

job

to

guide

the

truck

up

to

the

paver and signal

the

driver

when

and

how

much to

dump

into

the

hopper. Truck drivers roost maintain

a light pressure on his brakes to keep

truck

from

dumping material

on

the roadway. See figure 20. If

your

paver is equipped with a

truck

hitch, the truck·

driverwill

not

be requiredto maintainpressureon the

brake. See page 10, figure 7.

E. Always pave in

Low

range.

F. If paveris equipped with a truck hitch, referto Truck

Hitch Attachment instruction on page 10.

!

DANGER!

BEFORE

STARTING

FORWARD

WITH

PAVER

MAKE

SURE

NO

ONE

IS IN FRONT OF

IT.

Loading...

Loading...