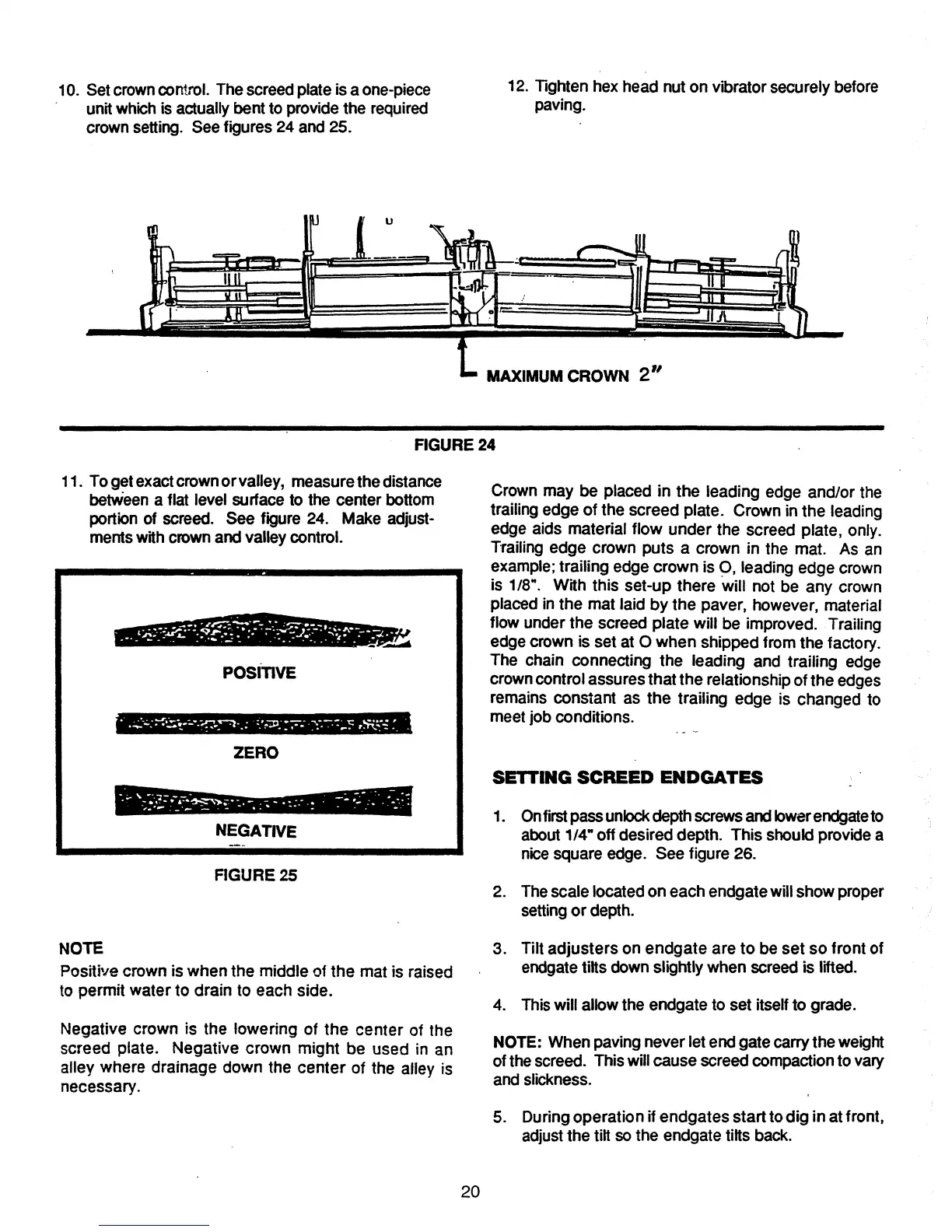

10. Set crown

control.

The screed plate is a one-piece

unit which is

adually

bent to provide the required

crown setting. See figures

24 and 25.

12. Tighten hex head nut on vibrator securely before

paving.

MAXIMUM CROWN

2"

FIGURE24

11. To get exactcrown

or

valley, measure

the

distance

betWeen a flat level surface to the center bottom

portion of screed.

See

figure 24. Make adjUst-

ments with crown and valley control.

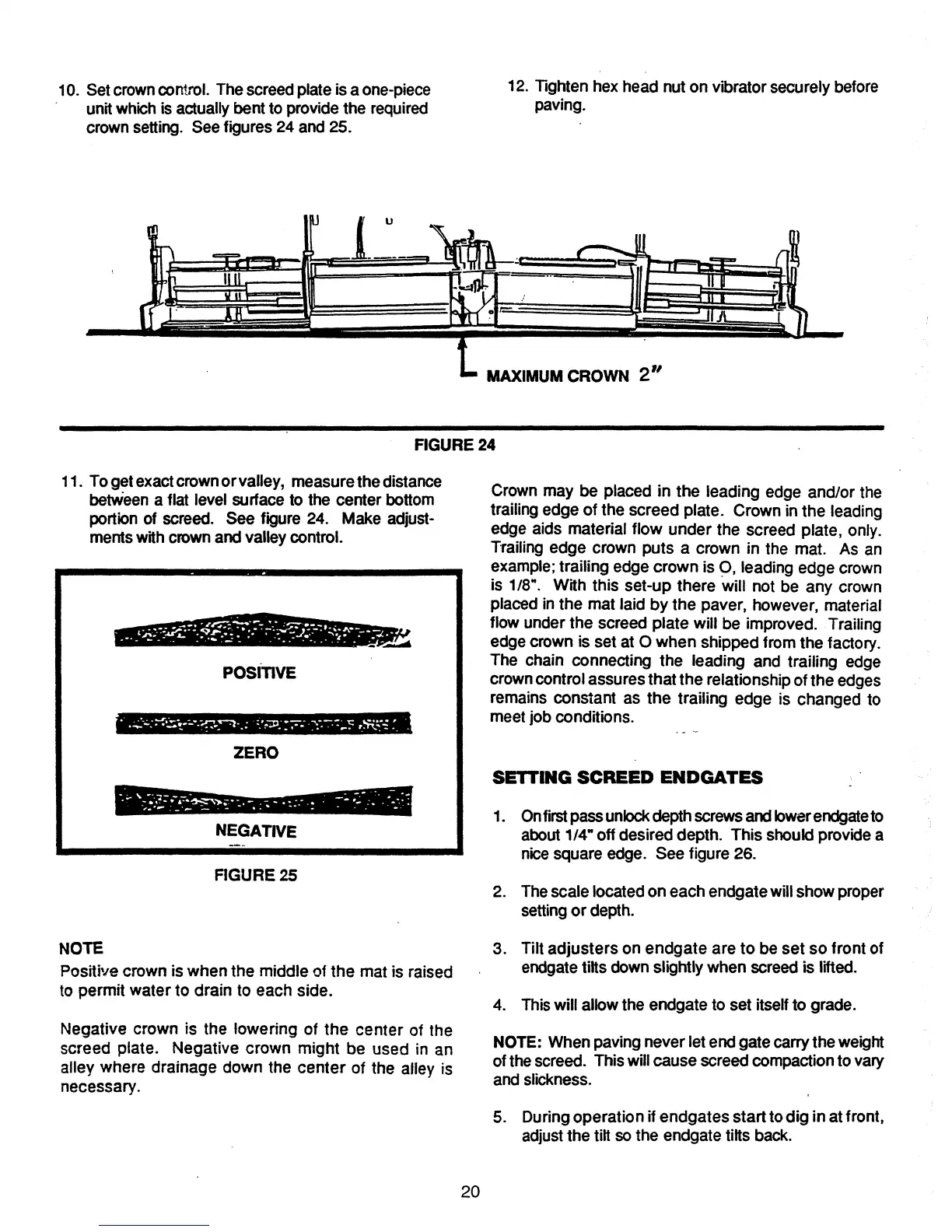

posinVE

ZERO

NEGATIVE

FIGURE 25

NOTE

Positive

crown

is

when

the

middle

of

the

mat

is raised

to

permit

water

to

drain

to

each

side.

Negative

crown

is the

lowering

of

the

center

of

the

screed plate. Negative crown might be used in an

alley

where

drainage

down

the

center

of the alley is

necessary.

20

Crown

may

be placed in

the

leading edge

and/or

the

trailing

edge

of

the

screed

plate.

Crown

in

the

leading

edge aids material

flow

under

the

screed plate, only.

Trailing

edge

crown

puts

a crown in the mat. As an

example; trailing edge

crown

is 9, leading

edge

crown

is 1/8". With this

set-up

there

will

not be

any

crown

placed in

the

mat

laid by

the

paver, however, material

flow under

the

screed

plate

will be improved

..

Trailing

edge crown is

set

at 0

when

shipped from

the

factory.

The chain connecting

the

leading and trailing edge

crown control assures

that

the

relationship of

the

edges

remains

constant as the trailing edge is

changed

to

meet job conditions.

SETTING SCREED ENDGATES

1. Onfirstpass

unlock

depth

screws

and

lower

endgate to

about1/4"off desired depth.

This

should provide a

nice square edge.

See

figure 26.

2.

The scale located on

each

endgatewill

show

proper

setting

or

depth.

3.

Tilt

adjusters

on

endgate

are

to

be

set

so

front

of

endgate tilts down slightly

when

screed is lifted.

4. This will allowthe endgate to set itself to grade.

NOTE: When paving never let end gatecarry

the

weight

of the screed. This will

cause

screed compaction to vary

and slickness.

5. During

operation

if

endgates

start

to

dig

in at front,

adjust the tilt so the endgate tilts back.

Loading...

Loading...