DIRECTIONAL CONTROL ADJUSTMENT

GENERAL

There

are

two adjustments required to make the machine

run straight. One is to the control cables, the other is to

the adjustment screws

located

on each

torque

hub

motor. To keep

the

machine

running

straight follow

the instructions below.

FORWARD OR REARWARD (cable correction)

When

starting

forward with

forward/reverse

levers

push handles together.

If

machine

veers left or '

right

adjustment

is required.

Make

adjustment

to

control cable clevis connection at

the

pump. This may

be done by adjusting cable clevis. After adjustment,

pumps should be in sequence.

!

DANGER!

DO NOT

SUBSTITUTE

FASTENERS

OF

ANY

KIND

UNLESS

THEY

ARE

EQUAL

IN

SIZE

AND

GRADE

AS

ORIGINAL

EQUIPMENT.

28

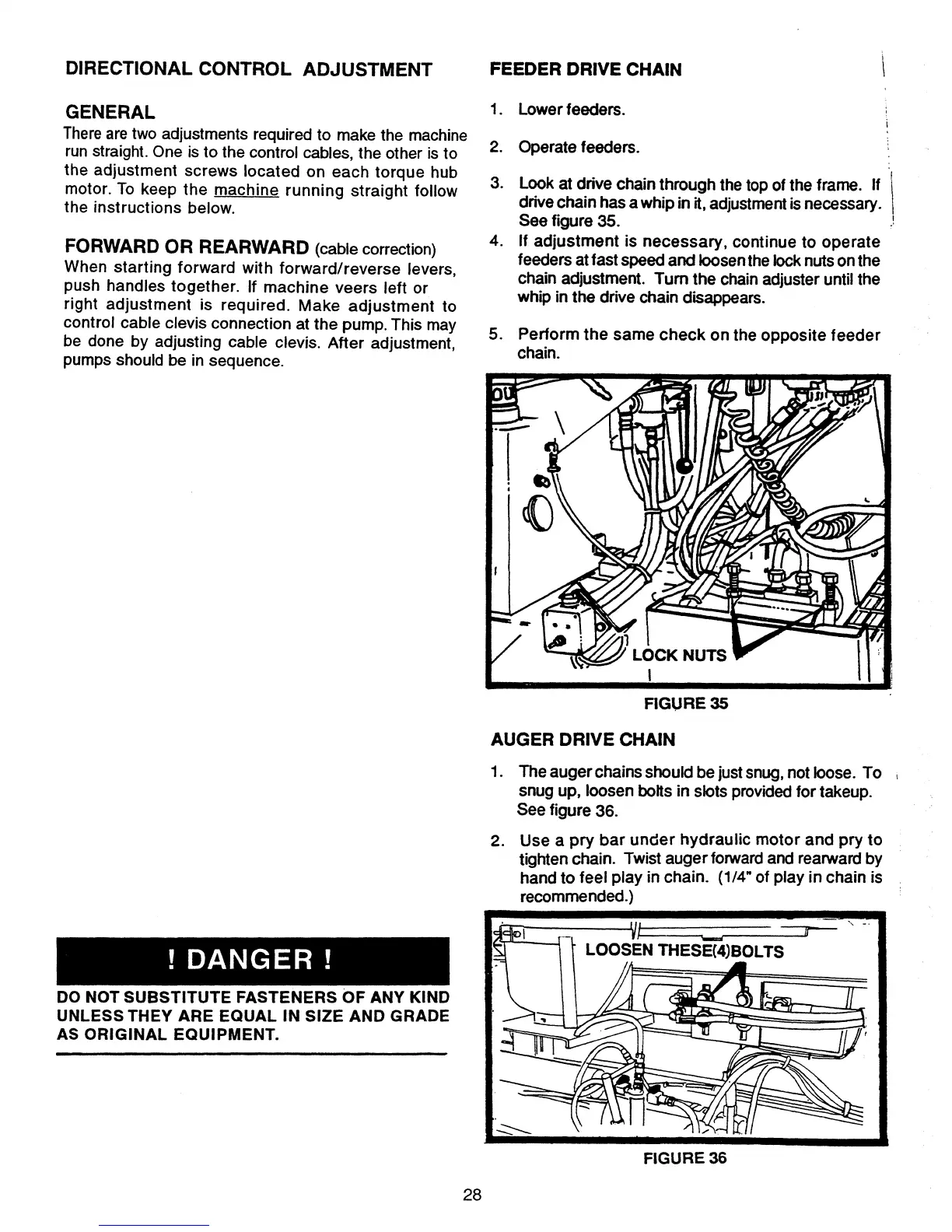

FEEDER DRIVE CHAIN

1. Lowerfeeders.

2. Operate feeders.

3. Look at drive chain through the top of the frame. If

drivechain hasawhipin it, adjustment isnecessary.

See figure 35.

4. If adjustment is necessaryt continue to operate

feedersatfast

speed and loosenthelock nutsonthe

chain adjustment.

Tum

the chainadjusteruntil the

whip in the drive chain disappears.

5. Perform the same check on the opposite feeder

chain.

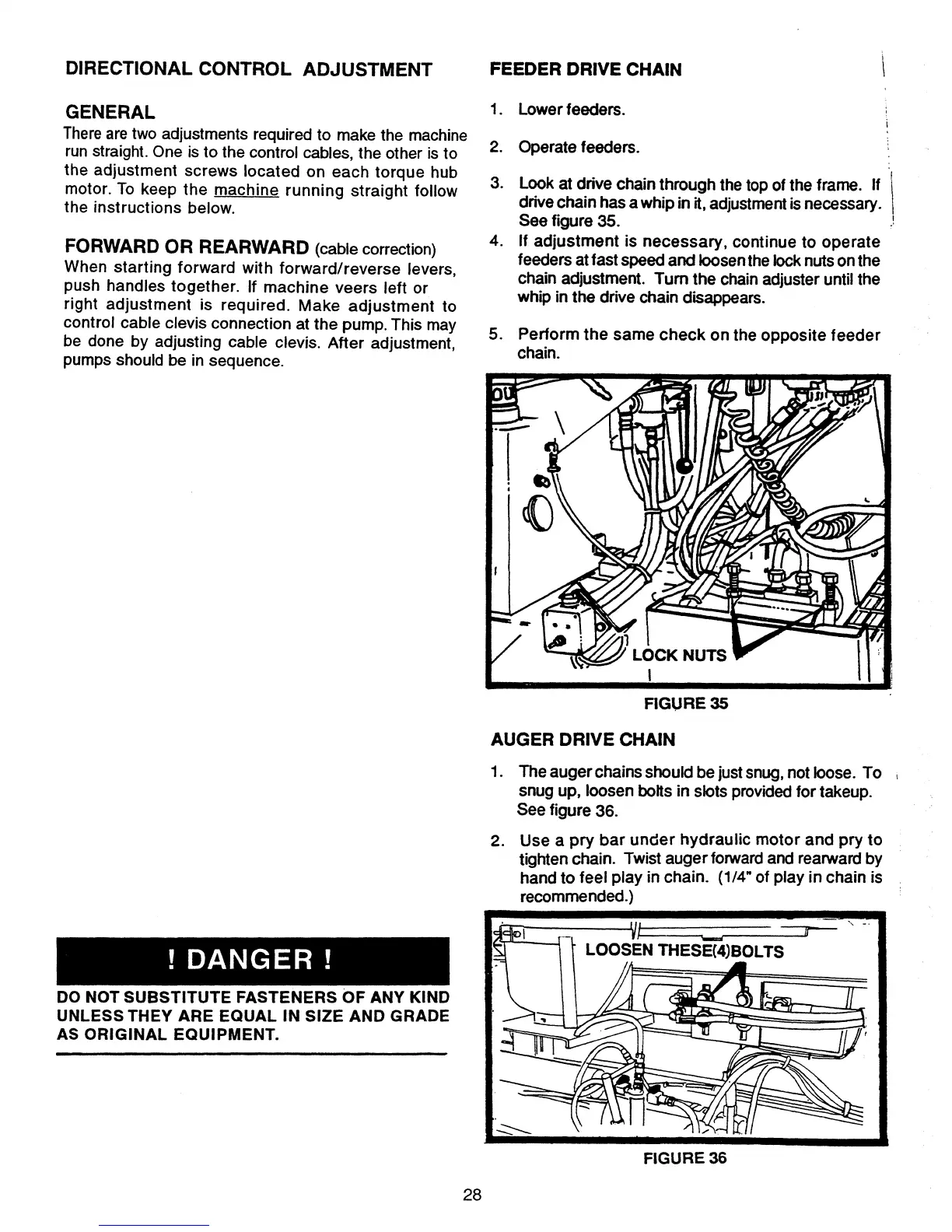

AUGER DRIVE CHAIN

1. The auger chains should be justsnug,not loose. To

snug up, loosen bolts in slots provided for takeup.

See figure

36.

2. Use a

pry

bar

under

hydraulic

motor

and

pry

to

tighten chain. Twist auger

forward

and rearwardby

hand to feel play in chain. (1/4" of play in chain is

recommended.)

f:JL'1-----J./I--------

---

" _.

FIGURE 36

Loading...

Loading...