-~

...........

i

\

I

I.

GAUGE

GAUGE

TILT/

CON-T~OL

HANDLE

2.

Adjust

tilt

on

rear

edge

of

extension

by

turning

T-

handle

counter-clockwise.

This

is

done

to

give

the

same

amount

of

compaction

on

extension

and

slickness as main screed.

3. Ifdragoccurs, then too much pressureison the screed

extensionand the extensionis carryingall

the

weight.

Correct this

by turning the T-handle clockwise until

both

the

screed and the

screed

extension produce

the

same looking mat.

PAVER

OPERATION:

1.

Follow

start-up

procedures.

See

Engine

Start-Up,

page 8.

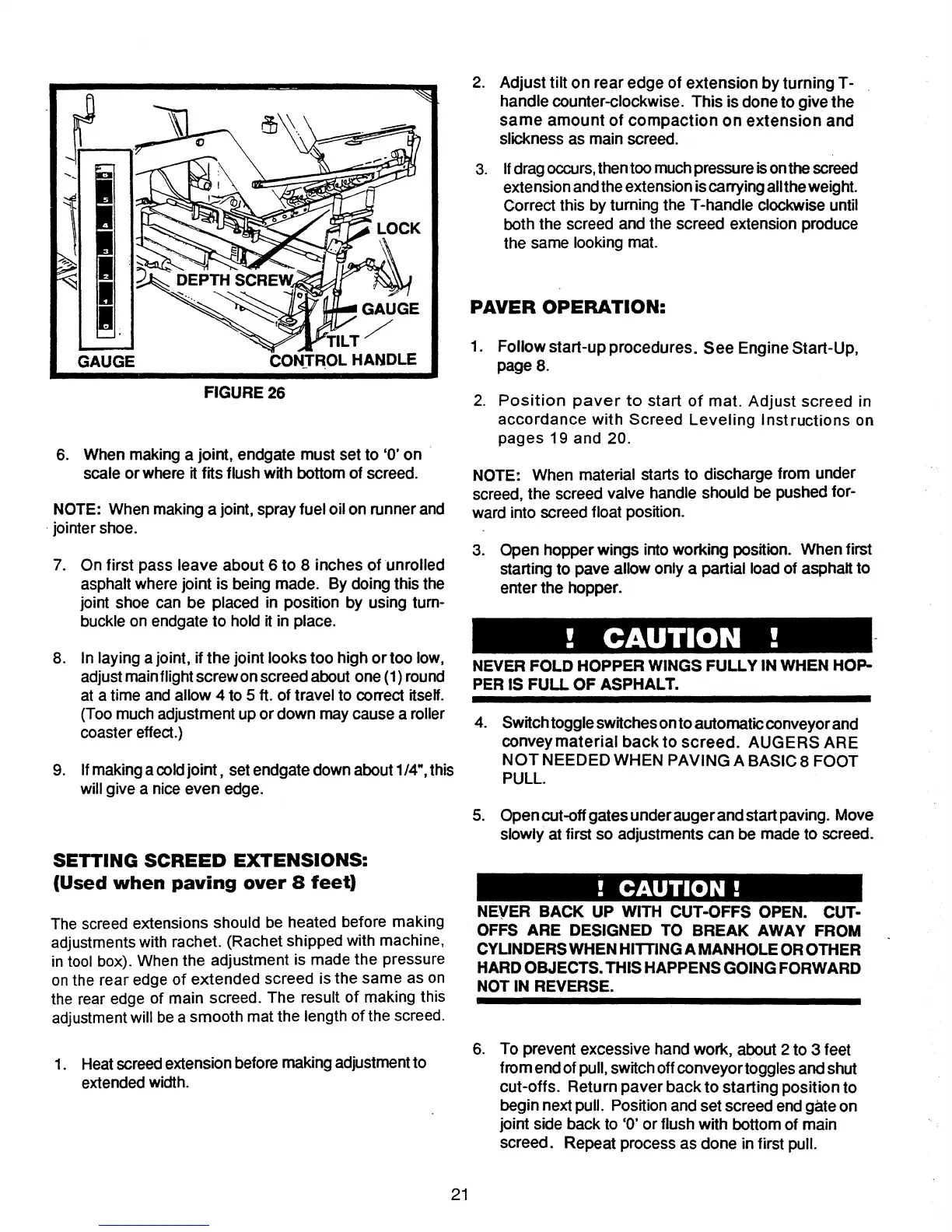

FIGURE

26

6.

When

making a joint,

endgate

must

set to '0'

on

.

scale

or

where it fits flush

with

bottom of screed.

NOTE: When making a joint,

spray

fuel

oil on runner and

. jointer shoe.

7. On

first

pass

leave

about

6 to 8

inches

of

'unrolled

asphalt where

joint

is being

made.

By

doing

this the

joint shoe can

be

placed in position by using turn-

buckle on endgate to hold it in place.

8. In

laying

a joint, if

the

joint

looks

too

high

ortoo

low,

adjustmain flight

screw

on

screed

about one (1) round

at a time and

allow

4 to 5 ft. of travel to correct itself.

(Too much adjustment

up

or

down

may cause a roller

coaster effect.)

9. If makinga cold

joint

, set endgate

down

about1/4",this

will give a nice

even

edge.

SETTING

SCREED

EXTENSIONS:

(Used

when

paving

over

8

feet)

The screed extensions should be heated before making

adjustments with rachet. (Rachet shipped with machine,

in tool box). When the adjustment is made the pressure

on the rear edge of extended screed is the same as on

the rear edge of main screed. The result of making this

adjustment will be a smooth mat the length of the screed.

1. Heat screed extension before making adjustmentto

extended width.

21

2.

Position

paver

to

start

of

mat.

Adjust

screed

in

accordance

with

Screed

Leveling

Instructions

on

pages

19 and 20.

NOTE:

When

material starts to discharge

from

under

screed,

the

screed valve handle

should

be pushed for-

ward into screed float position.

3.

Open

hopper

wings

into

working

position. When first

starting to

pave

allow

only

a partial load of asphalt to

enter

the

hopper.

!

CAUTION

!

NEVER

FOLD

HOPPER

WINGS

FULLY

IN

WHEN

HOP-

PER IS

FULL

OF

ASPHALT.

4.

Switch

toggleswitcheson to

automatic

conveyor

and

convey

material

back

to

screed.

AUGERS

ARE

NOTNEEDEDWHEN

PAVING A BASIC 8

FOOT

PULL.

5.

Open

cut-off

gates

under

auger

and

startpaving.

Move

slowly at first so

adjustments

can

be

made

to screed.

!

CAUTION!

NEYER

BACK

UP

WITH

CUT-OFFS

OPEN.

CUT-

OFFS

ARE

DESIGNED

TO

BREAK

AWAY

FROM

CYLINDERS

WHEN

HITTINGA

MANHOLE

OR

OTHER

HARD

OBJECTS.

THIS

HAPPENS

GOING

FORWARD

NOT

IN

REVERSE.

6. To prevent excessive hand

work,

about 2 to 3 feet

from

end of pull, switchoff

conveyor

toggles

and

shut

cut-offs.

Return

paver

back

to

starting

position

to

begin

next pull. Position and set

screed

end

gate

on

joint side

back

to '0'

or

flush

with

bottom

of

main

screed.

Repeat

process as

done

in first pull.

Loading...

Loading...